Bottle steering mechanism

A steering mechanism and bottle technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of bottle conveying to the target position and the wrong orientation of bottle 8

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

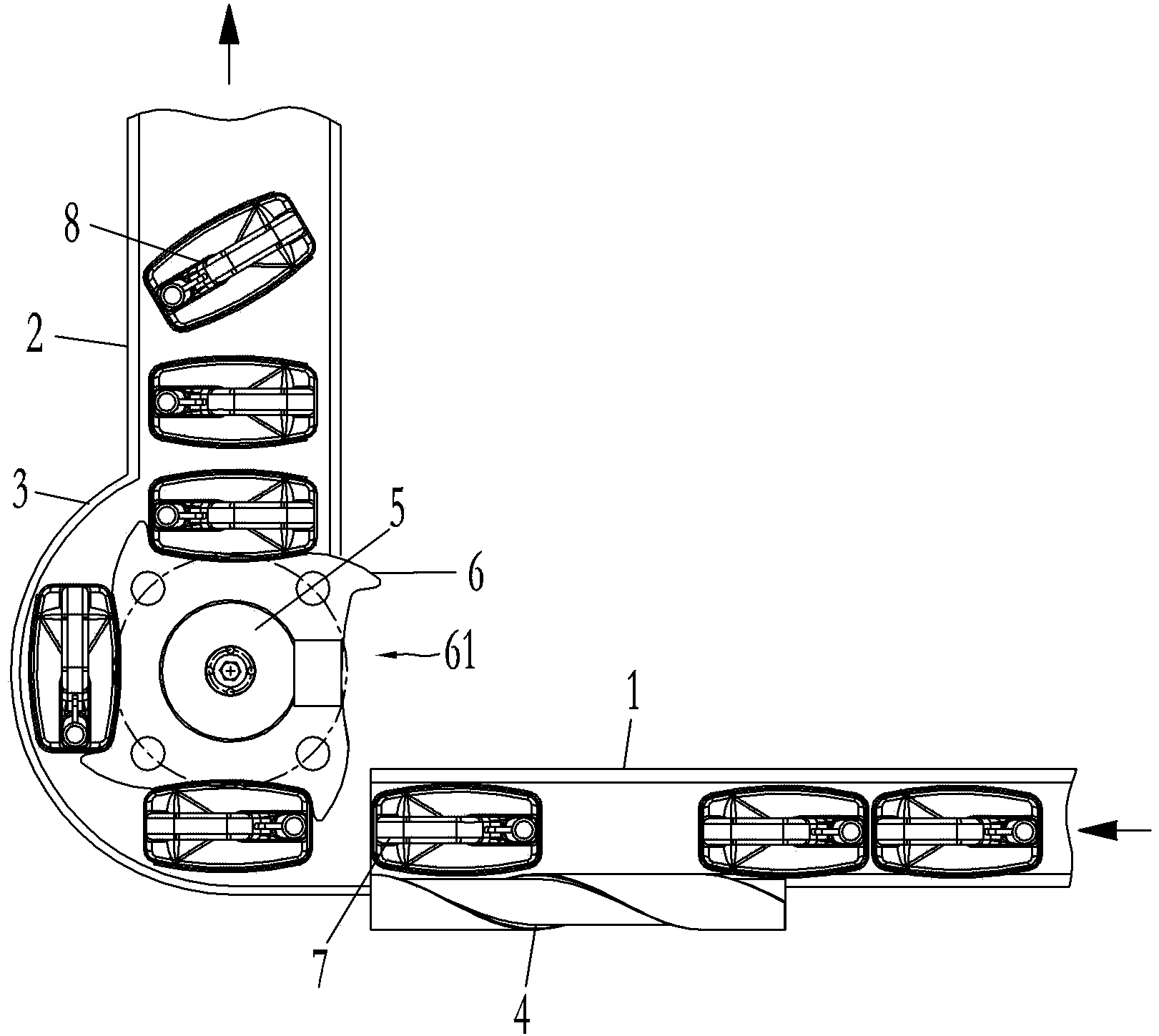

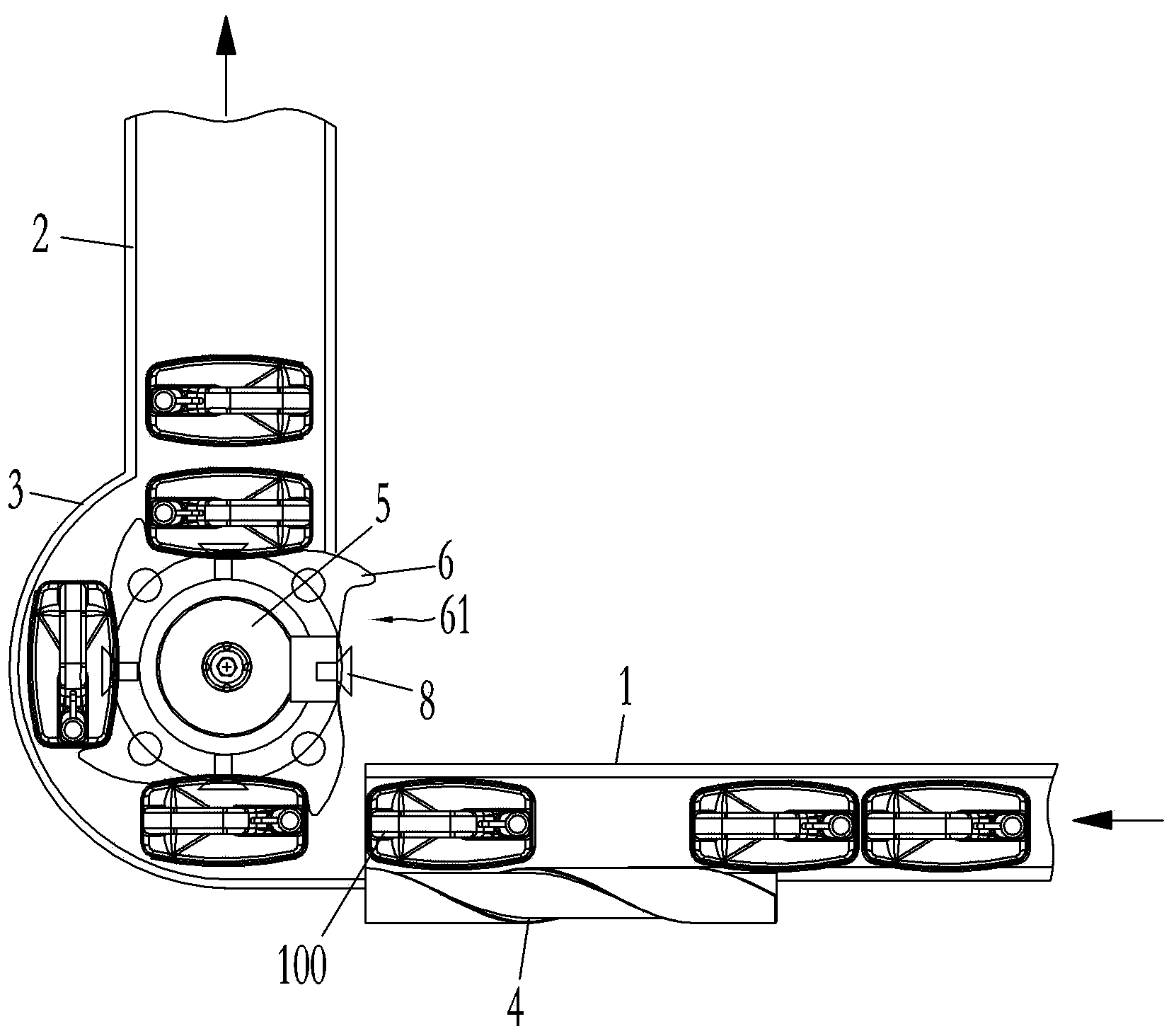

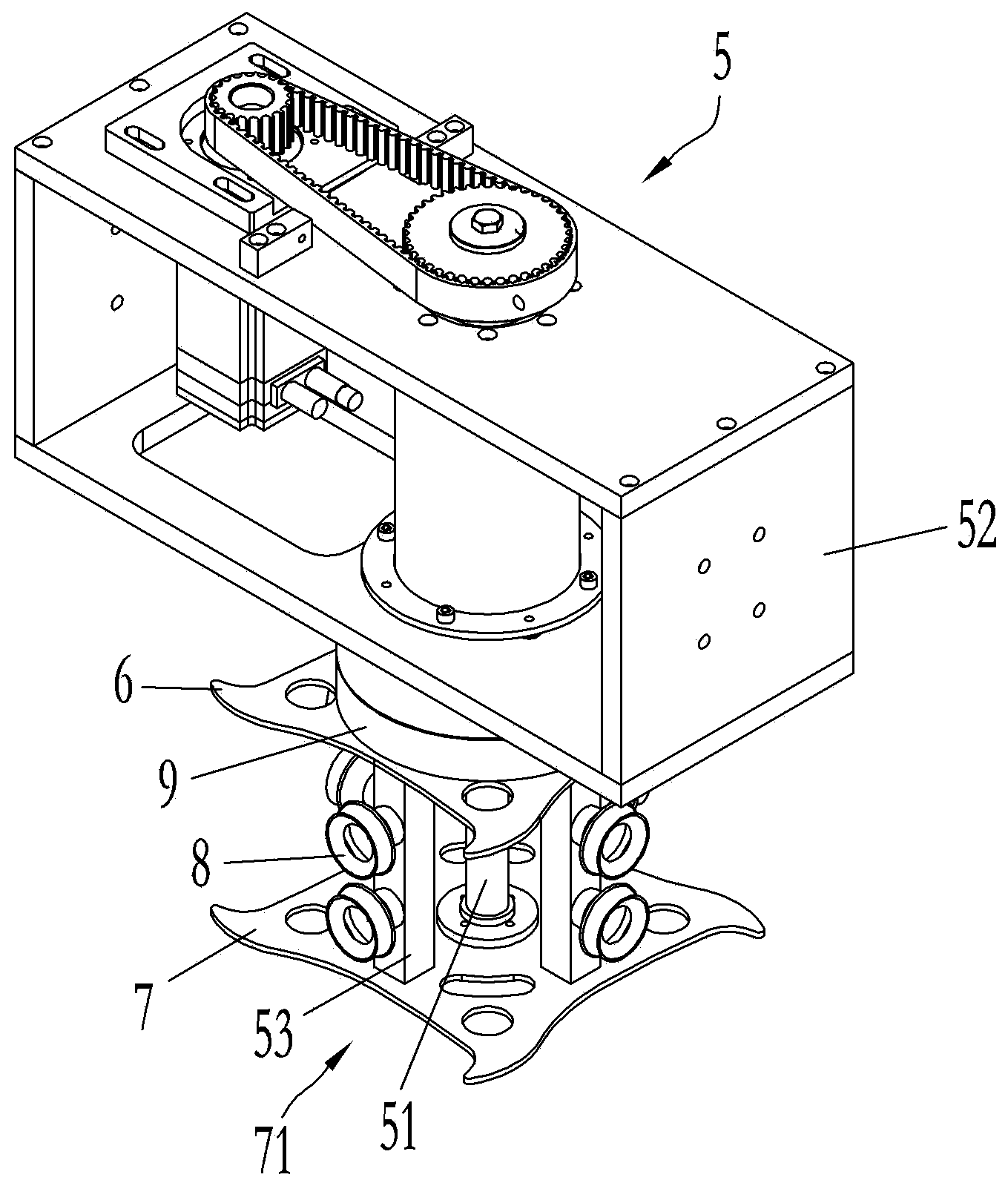

[0017] Such as Figures 2 to 9 As shown, the bottle steering mechanism includes a guardrail 3 docked with conveying devices 1 and 2 in two different conveying directions upstream and downstream, a screw positioning device 4 and a rotating device 5 located inside the guardrail 3, the rotating The upper and lower parts of the rotating shaft 51 of the device 5 are provided with claws 6, 7 that rotate with the rotating shaft, and the upper and lower claws 6, 7 have a plurality of corresponding slots 61, 71 that can hold the bottle 100 therein. , as shown in the figure, it is the case of four card slots, which are evenly distributed around the rotating shaft 51, and the position of the card slots 61, 71 is provided with a follower claw 6 between the upper and lower claws 6, 7. , 7 rotating suction cup 8, the suction cup 8 cooperates with the vacuuming device (not shown in the figure, it can be fixed on the fixed frame 52 of the rotating device, or can be fixed at other positions), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com