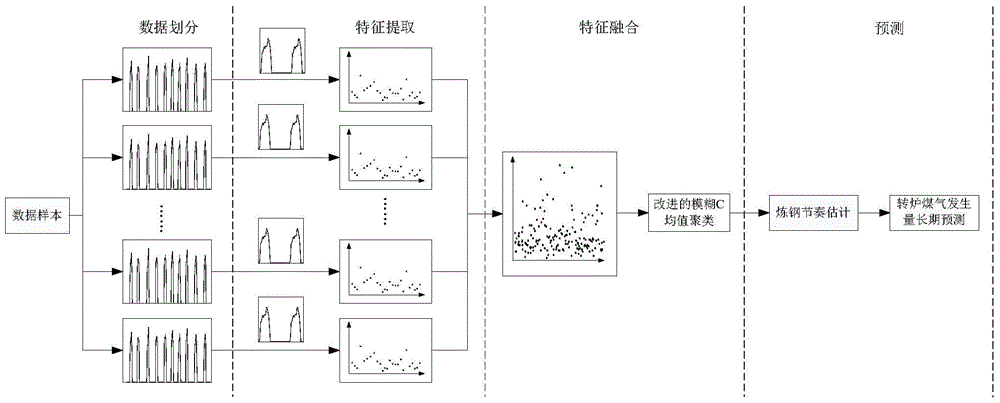

Long-term prediction method of converter gas generation in metallurgical enterprises based on steelmaking rhythm estimation

A converter gas and prediction method technology, applied in the information field, can solve problems such as long-term prediction of converter gas generation, and achieve the effect of improved prediction accuracy and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

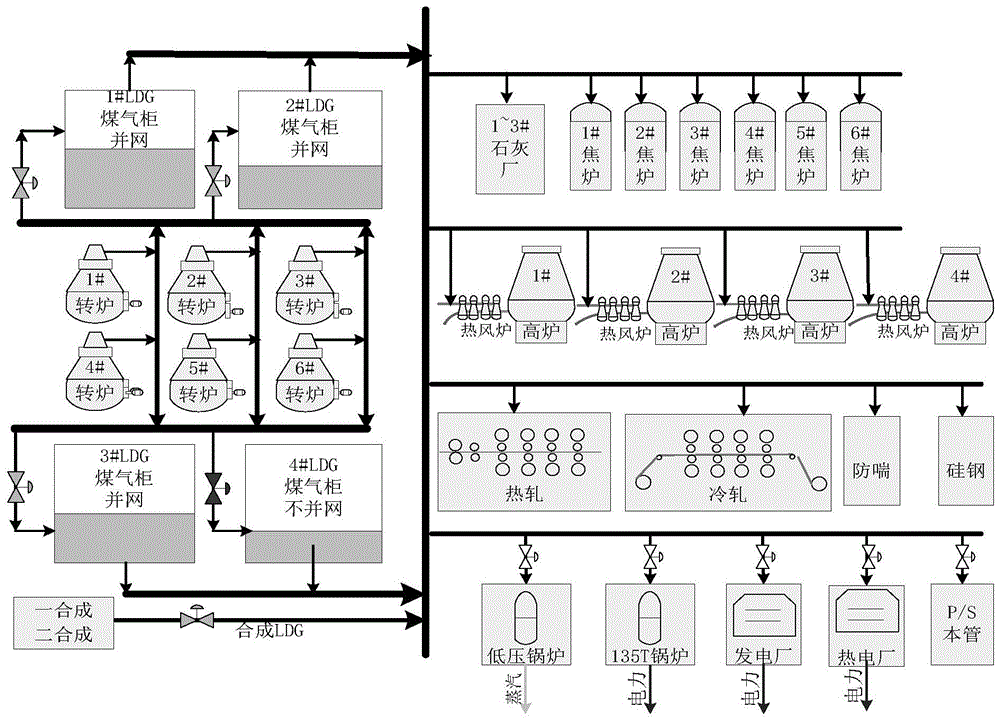

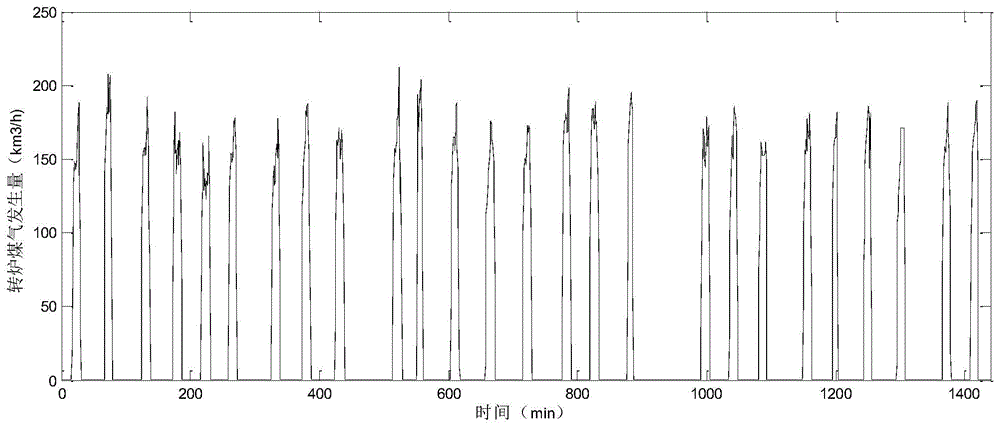

[0024] In order to better understand the technical solution of the present invention, the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 2 It is a pipe network diagram of a converter gas system in a metallurgical enterprise. The sources of converter gas are 6 converters, which generate about 27km per hour. 3 The blast furnace gas will enter the grid-connected gas cabinet through the gas pipeline network, and then be distributed to various users. Since the amount of converter gas is affected by the pace of converter steelmaking, the series of converter gas generation shows as follows: image 3 The form shown, that is, each peak in the figure represents a heat of steel in the converter. Although on-site gas dispatchers can complete a simple long-term prediction of converter gas generation through manual real-time monitoring, combined with factors such as steelmaking production plans, maintenance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com