Wire box

A silk box and silk material technology, applied in processing material handling, manufacturing tools, additive manufacturing, etc., can solve problems such as easy to change moisture, affect printing quality, affect printing process and printing quality, and meet the requirements of reducing use conditions , The effect of saving the use of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

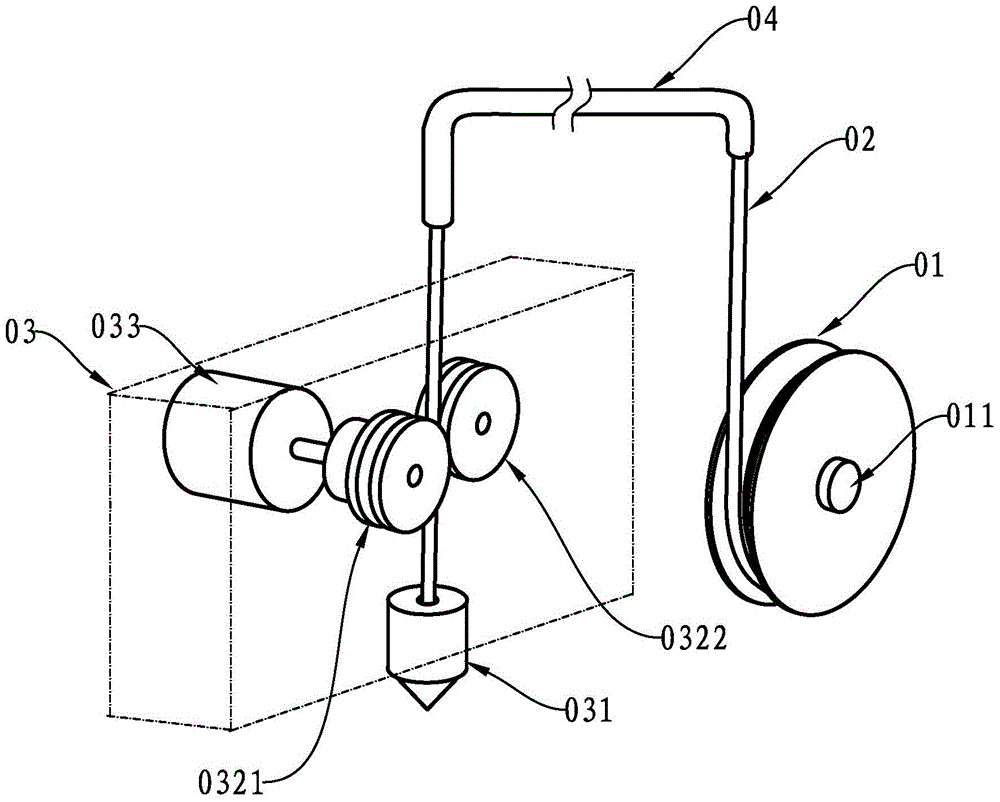

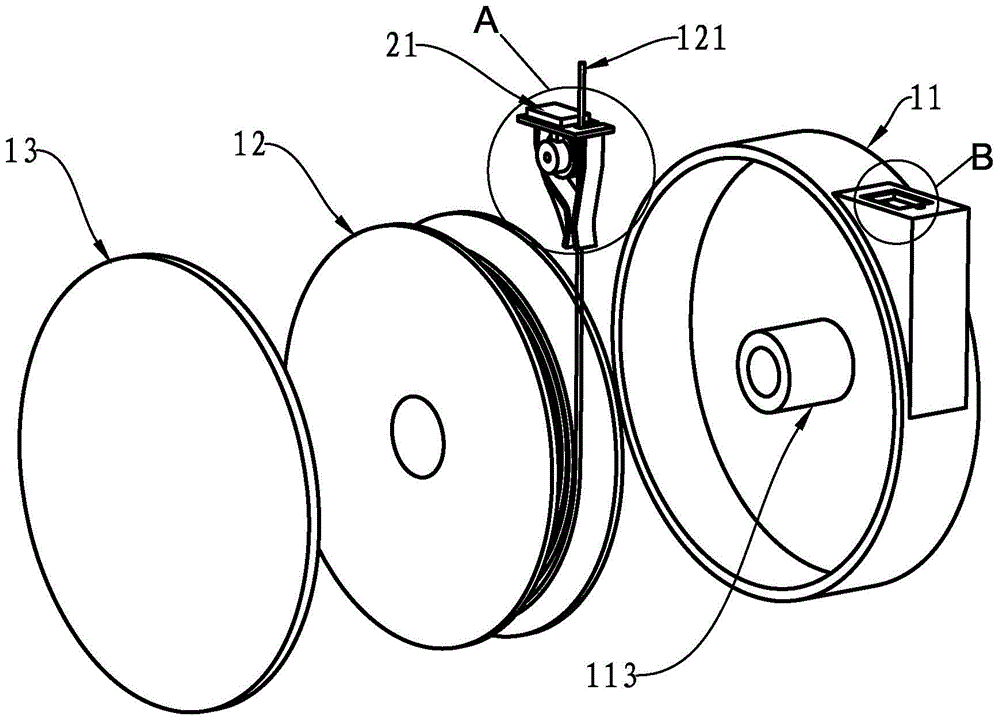

[0025] see figure 2 , the wire material box consists of a base 11, a cover 13, a reel, a wire material 121 wound on the reel, a display screen 21, a substrate and a counting wheel located on the substrate, a control memory, a sensor, an alarm and a pair of elastic board composition.

[0026] see Figure 3 to Figure 5 , the base 11 cooperates with the cover 13 to form a box with a silk outlet 111, the base 11 is provided with a rotating shaft 113, and the reel 12 wound with the silk 121 is rotatably installed on the rotating shaft 113; A mounting hole 112 of a display screen 21 is formed near the material outlet 111, and the display screen 21 is electrically connected to the control memory located on the substrate 22 for displaying data information such as the amount of silk material in the control memory; the counting wheel 24 is fixed on On the base plate 22, one end of a pair of elastic plates 231 and 232 is fixed on the base plate 22, and the other ends are pressed again...

no. 2 example

[0029] As a description of the second embodiment of the present invention, only the differences from the above-mentioned first embodiment will be described below. The above-mentioned pair of elastic plates are replaced by a pair of springs, and one end of one of the springs in the pair of springs is fixed to the bottom of the base. On the side wall, one end of the other spring is fixed on the corresponding position of the face cover, and the other ends of the pair of springs are fixed with pressure blocks. When the face cover is installed on the base, the two pressure blocks are tightly pressed and form a cross-sectional area smaller than The cross-sectional area of the filament channel.

no. 3 example

[0031] As a description of the third embodiment of the present invention, only the differences from the above-mentioned first embodiment are described below, and the above-mentioned substrate and the control memory, sensor and display screen, elastic plate and alarm are replaced by a mechanical counter. The device is installed on the mechanical counter, and the rotating shaft of the mechanical counter is fixedly connected with the rotating shaft of the counting wheel. In this example, the elastic plate is electrically connected with the alarm as the opening switch of the alarm.

[0032]The idea of the present invention is mainly to provide a metering unit for measuring the amount of wire used near the outlet of the wire box, a friction unit for controlling the force and speed of the wire output from the wire box, and a friction unit for displaying the wire output of the wire box. A display unit for the remaining or used amount of silk in the silk box; it is convenient for mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com