Drilling method for achieving PCB high hole-site precision

A technology of PCB board and drilling method, which is applied in the field of PCB manufacturing, can solve the problems of high input cost, limited improvement effect, unfavorable promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

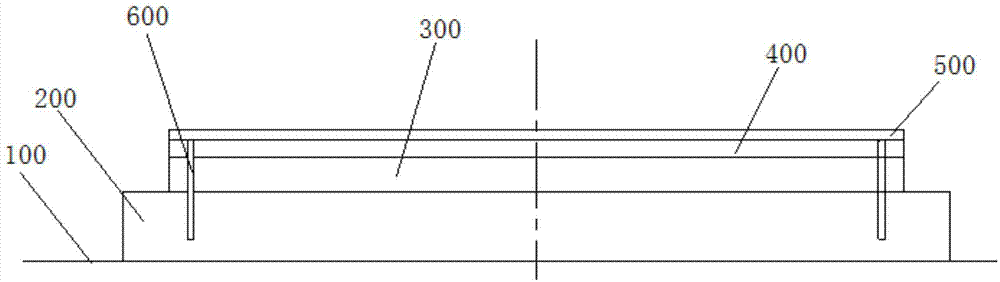

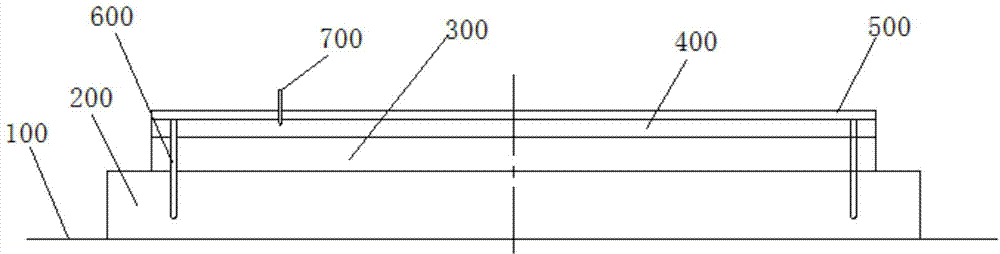

[0026] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

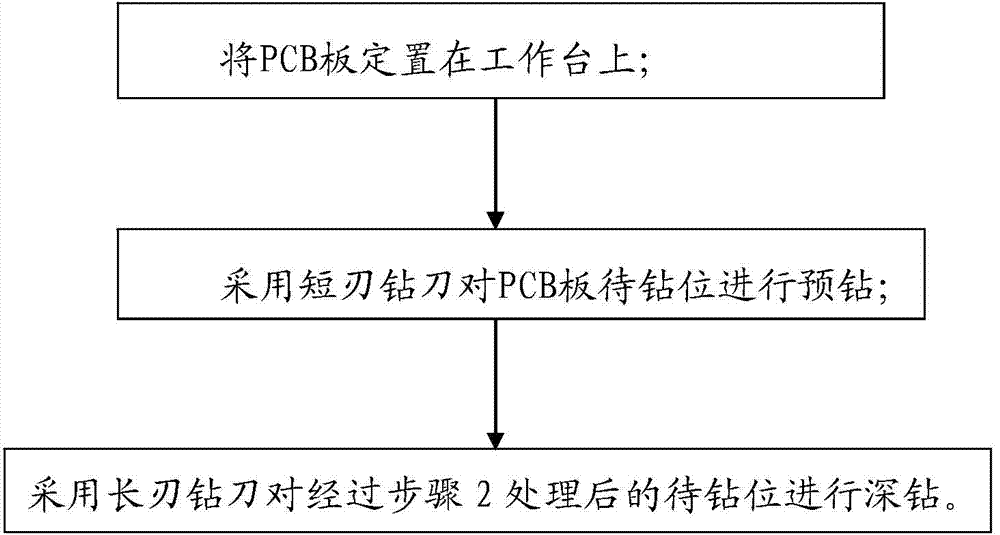

[0027] refer to Figure 1 to Figure 4 , a drilling method for realizing high hole position accuracy of a PCB, comprising the steps of:

[0028] Step 1, fix the PCB board on the workbench;

[0029] Step 2, use a short-edged drill to pre-drill the PCB board to be drilled;

[0030] Step 3, using a long-edged drill bit to perform deep drilling on the position to be drilled after step 2.

[0031] The drilling method for realizing the high hole position accuracy of the PCB board described in this embodiment is to fix the PCB board through step 1, so as to avoid the movement of the PCB board during the drilling process and affect the drilling accuracy; The drill position is pre-drilled, so that the PCB board is to be drilled to drill a shallow hole first. Since the short-blade drill is more rigid than the long-blade drill, it is not easy to slip when it touches th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blade length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com