Injector for nasal feeding

A syringe and nasal feeding technology, applied in the field of medical equipment, can solve problems such as waste of resources, easy spillage of food, pollution, etc., and achieve the effects of reducing workload, improving utilization rate, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

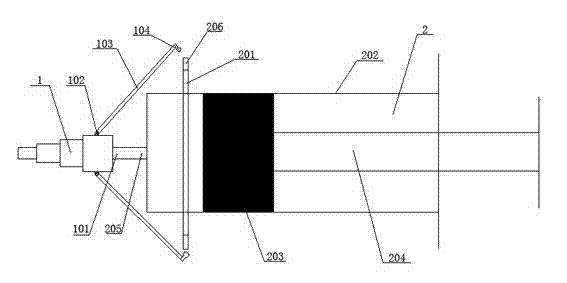

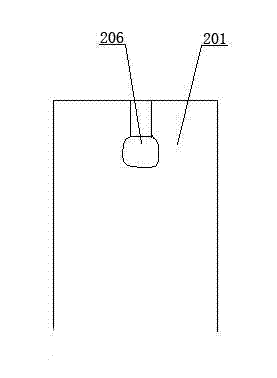

[0009] The syringe for nasal feeding includes a cylinder body 202, a piston head 203, a push rod 204 and a nipple 205. One end of the syringe 2 with the nipple 205 is provided with a hand rest 201 to prevent slipping. The groove 206 matched with the head 104, the upper port of the groove 206 is smaller than the lower port, the protrusion 104 on the connecting rod 103 is buckled in to achieve the effect of fixing the connecting body 1 on the syringe 2, and the protrusion 104 is set One end on the connecting rod 103, the other end of the connecting rod 103 is connected with the support 102 arranged on both sides of the connecting body 1, the interface 101 of the connecting body 1 communicates with the nipple 205 of the syringe 2, the connecting body 1 and the syringe 2 They are all made of heat-sterilizable poly-4-methylpentene, and the other end of the connecting body 1 is provided with bosses of different calibers for connecting gastric tubes of different types.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com