A full-scale borehole stability simulator

A wellbore stability and simulator technology, applied in boreholes/well components, measurement, earthwork drilling and production, etc., can solve problems such as limited measurement parameters, inability to simulate the mechanical environment, and inability to intuitively respond to the wellbore, to achieve optimal performance , intuitive observation, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

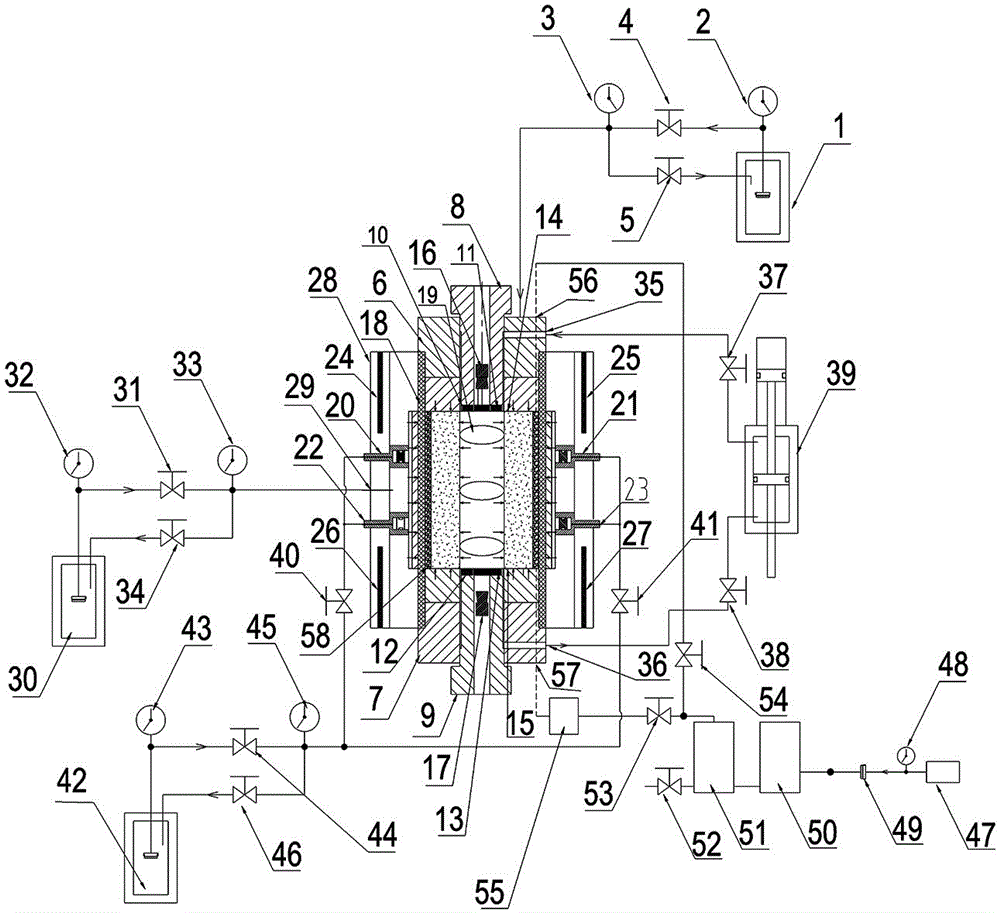

[0017] Such as figure 1 As shown, a full-scale wellbore stability simulator includes a cylindrical sealing rubber sleeve 18 sheathed outside the core. A pore pressure permeable layer 58 is provided between the core and the sealing rubber sleeve 18. The core is permeated by pore pressure. The layer 58 is in contact with the sealing rubber sleeve 18. A well diameter measuring instrument 19 is arranged inside the core. The two ends of the sealing rubber sleeve 18 are respectively installed with an upper axial pressure piston 6 and a lower axial pressure piston 7 for sealing the ports of the sealing rubber sleeve 18 Both the upper axial compression piston 6 and the lower axial compression piston 7 are provided with through holes communicating with the internal space of the sealing rubber sleeve 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com