Prepressing type movable trash compactor

A garbage compressor and pre-compression technology, which is applied in the directions of garbage conveying, garbage collection, loading/unloading, etc., can solve the problems of reducing garbage transportation efficiency, low garbage compression compactness, and high garbage moisture content, and achieves high transshipment costs. The effect of high waste loading and disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

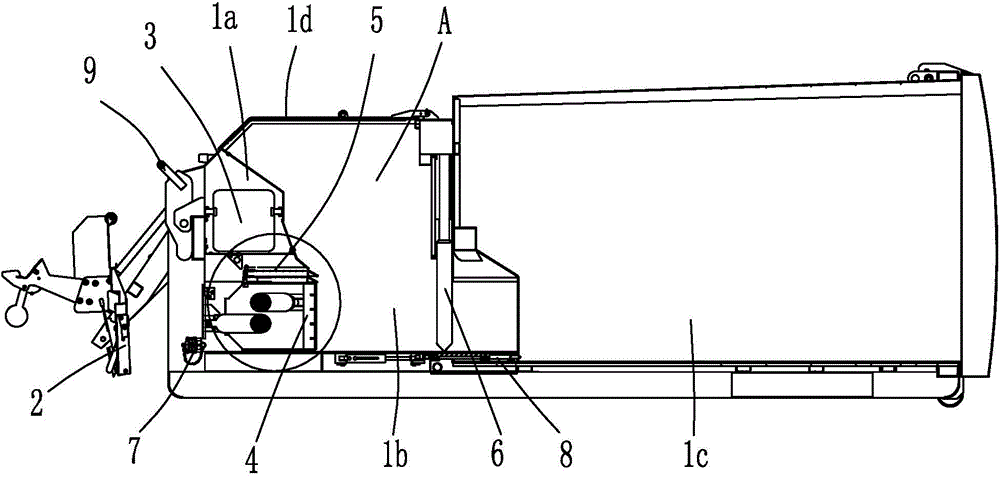

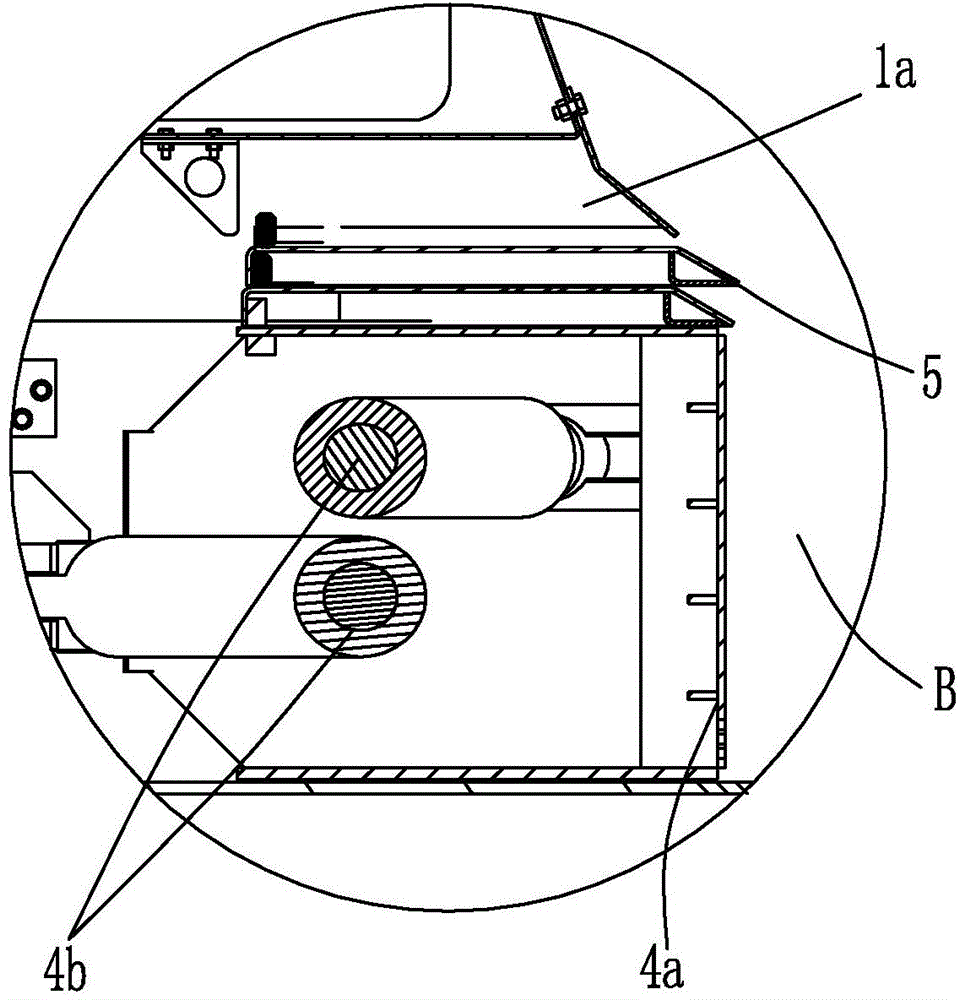

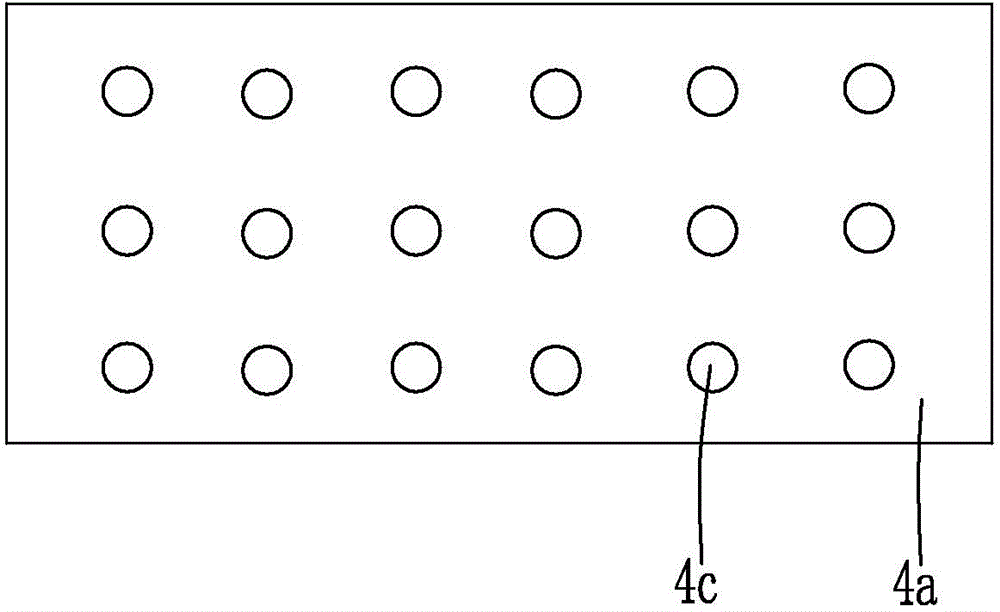

[0019] combine figure 1 , figure 2 As shown, a pre-pressurized mobile garbage compressor consists of a box structure, a flip feeding mechanism 2, a hydraulic control system 3, a pusher assembly 4, a retractable cover plate 5, a gate mechanism 6, and a main drainage system 7 , Auxiliary drainage system 8, suspension ring 9 etc. are formed. The box structure is composed of a liquid electric warehouse 1a, a push chamber 1b and a dustbin 1c, and the three are arranged in sequence from front to back.

[0020] The overturning feeding mechanism 2 is located directly in front of the box structure and is hinged on the box structure. There is a feeding port on the top of the push chamber 1b. The feeding port is equipped with an openable cover plate 1d, and the cover plate 1d is hinged on the box. body structure. The hydroelectric control system 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com