Centering and locating method for welding pipeline assembly

A technology of centering and positioning, pipeline group, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated construction, inconvenient welding construction of pipeline group, expensive equipment of the matching device, etc., to achieve the intuitive method of alignment The effect of clear, high centering accuracy and convenient calculation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

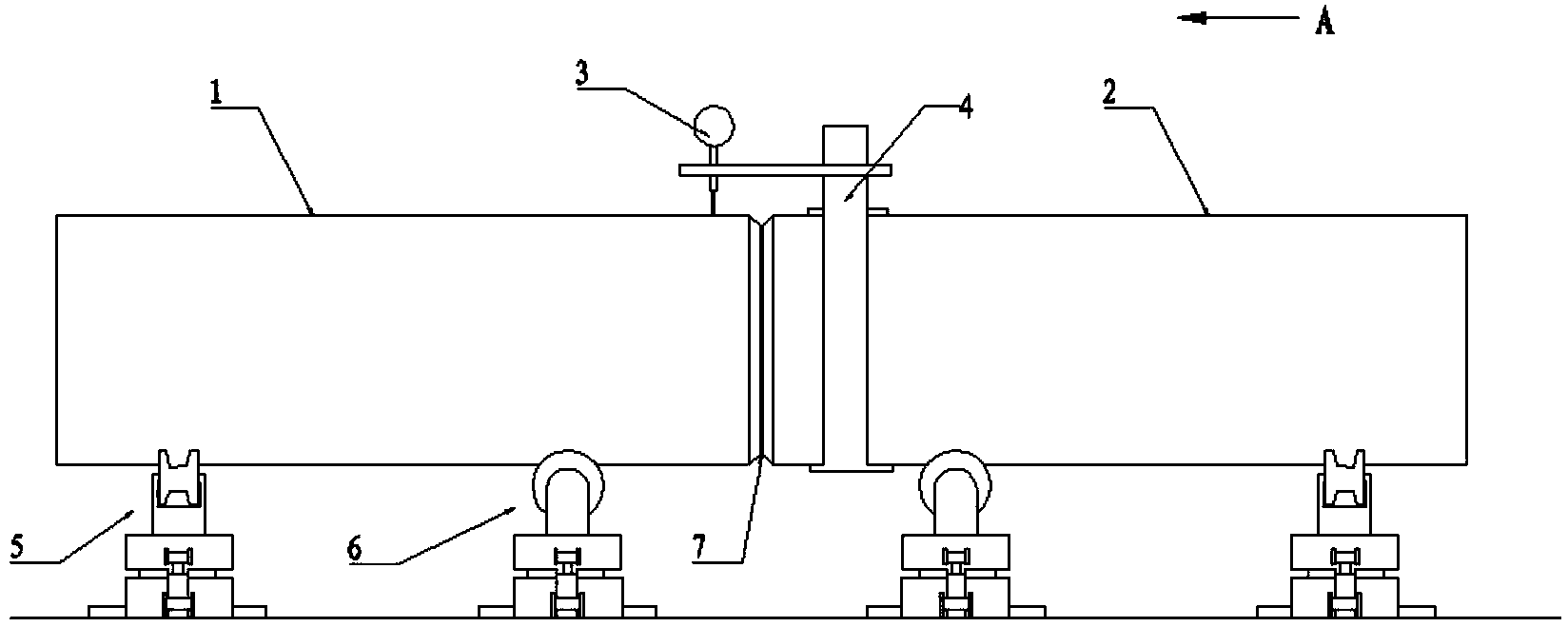

[0042] (1) Through the adjustment of the hydraulic tug-roll device, the pipeline is roughly centered first;

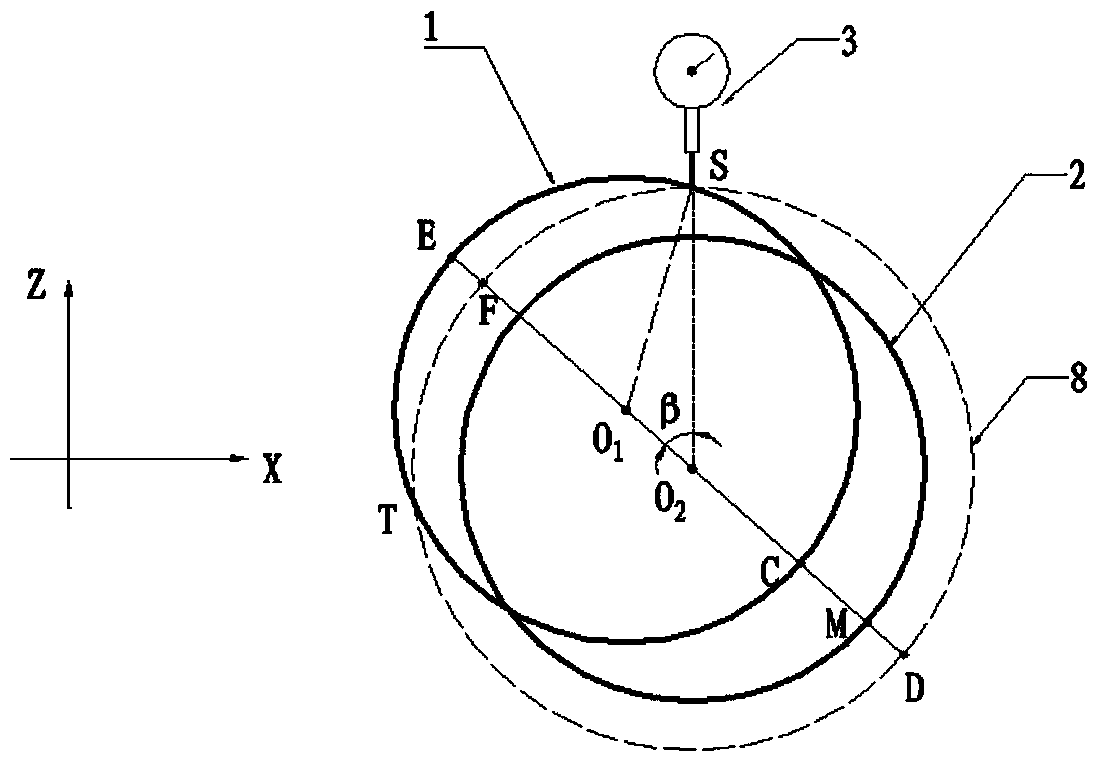

[0043](2) Fix the meter frame on the outer circumference of the rotated pipeline 2, adjust the measuring rod of the digital display dial gauge to be vertically downward, and make the measuring head touch any point S of the fixed pipeline 1 as the initial measurement position point;

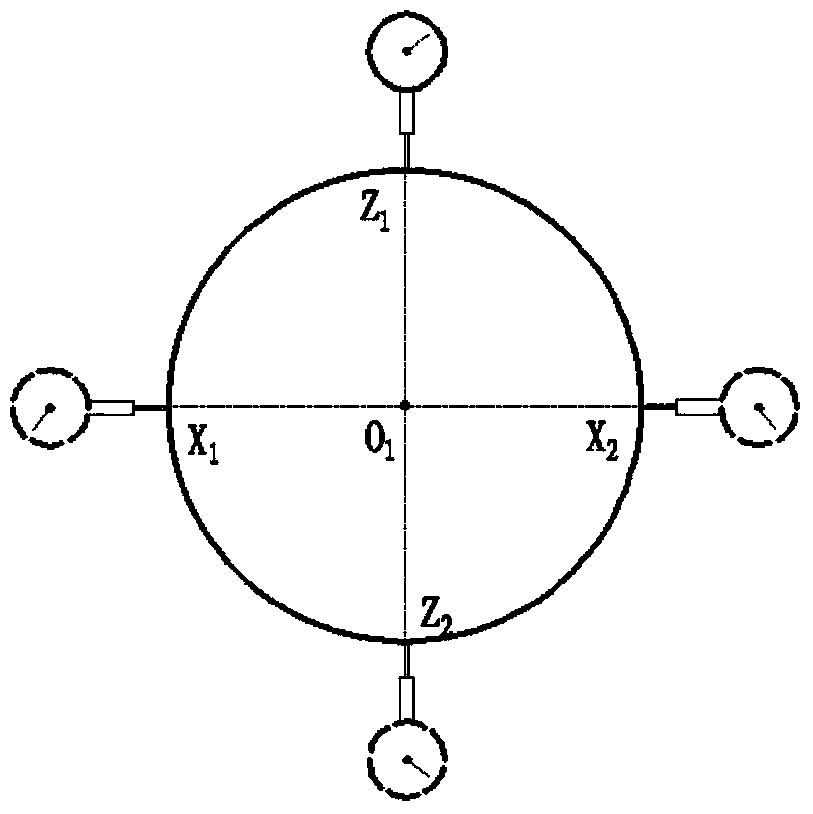

[0044] (3) Adjust the digital dial indicator to zero, and use the hydraulic tow-roll device to make the rotated pipeline 2 circle the center of the rotated pipeline O 2 The axis where it is located slowly rotates 360° clockwise, and write down the two maximum values of the absolute value change of the digital display dial indicator, that is, the maximum value |CD| in the two processes from S to T and from T to S , |EF|.

[0045] (4) Calculate the adjusted distance of the rotated pipeline 2 in the Z direction and the X direction, the calculation formula is as follows:

[0046] The adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com