Integrated slurry purifier with three-dimensional space

A technology of mud purification and three-dimensional space, which is applied in the direction of chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of inflexible working conditions, unfavorable mobile loading and unloading, large footprint, etc., and achieve a small footprint , The quality is stable and reliable, and the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

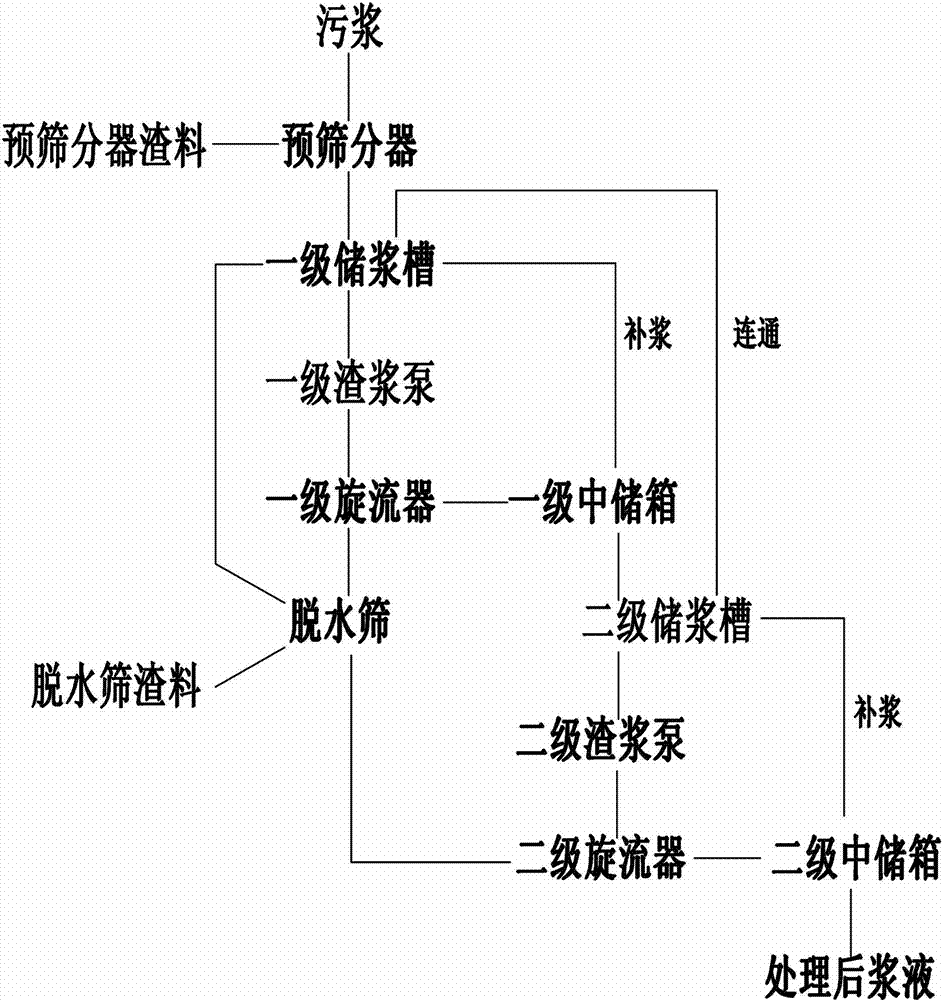

Method used

Image

Examples

example

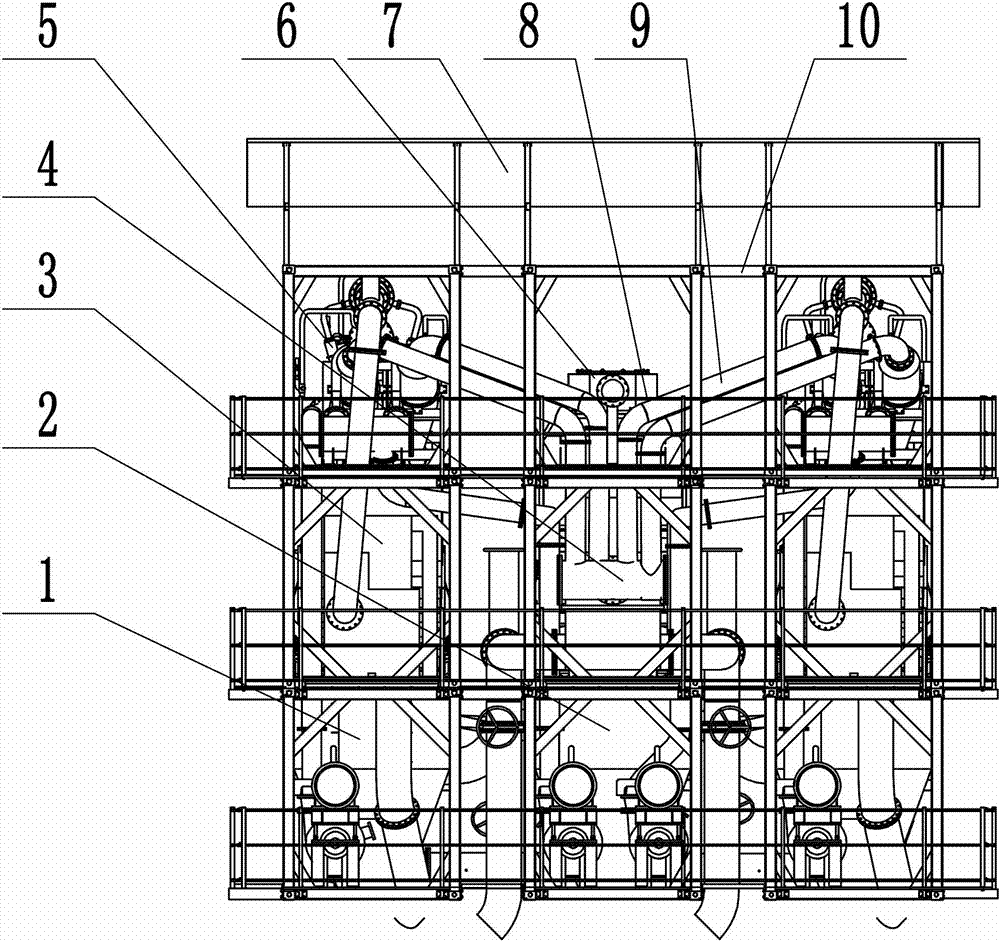

[0049] 1. Series operation:

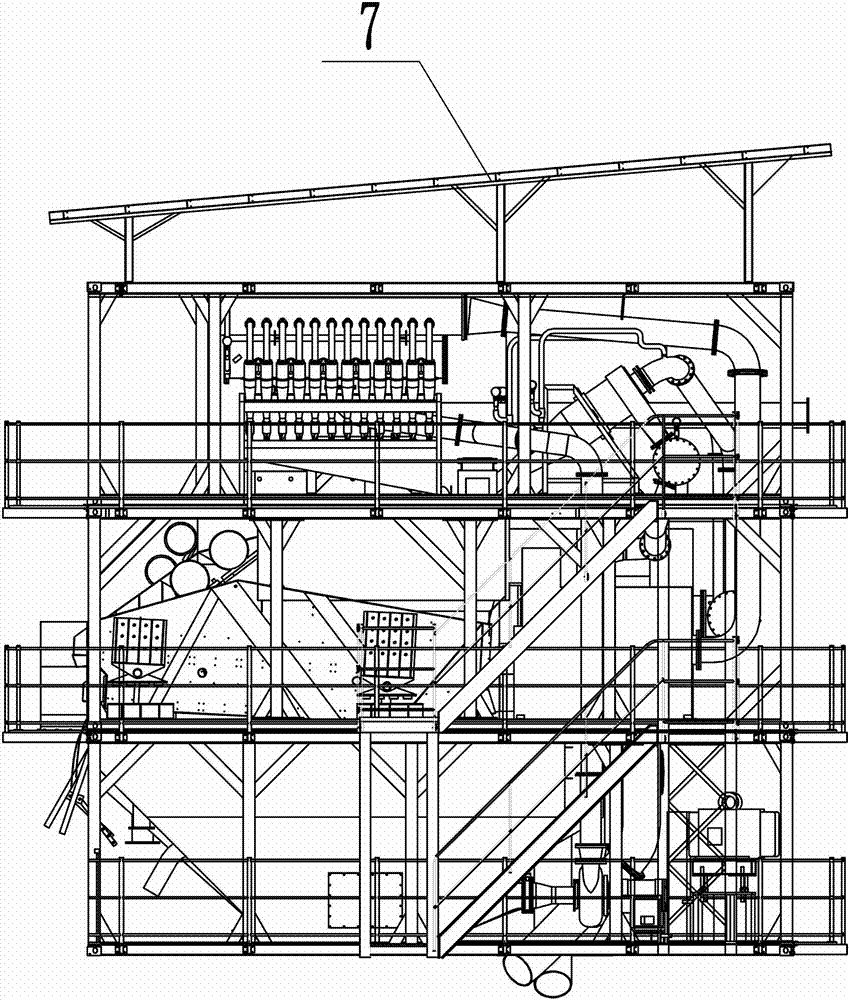

[0050] The slurry to be processed is transported into the slurry inlet tank of the total slurry inlet frame 6, and flows down to the pre-screen frame 4, where particles of more than 2 mm are separated by the pre-screen and discharged, and the under-screen slurry enters the primary slurry tank frame 2 in the middle of the lower layer. The primary slurry pump arranged in the primary slurry tank frame 2 transports the slurry to the primary cyclone of the cyclone frame 5 through the pipe valve system 9 for separation. The cyclone frame 5 is provided with multiple sets of cyclones which are switched into a multi-stage series structure, and the underflow of the cyclone enters the intermediate layer dewatering screen frame 3 and is separated by the dewatering screen for a second time. The residue on the screen is discharged, the slurry under the screen is collected by the collection tank arranged in the secondary slurry storage tank frame 1, and then flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com