High fructose syrup production wastewater treatment technology

A technology for production of wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments.

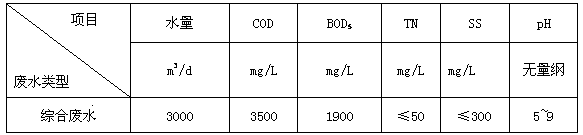

[0017] Table 1 shows the water quality indicators of wastewater discharged from a fructose syrup enterprise:

[0018]

[0019] Treatment process of the present invention is:

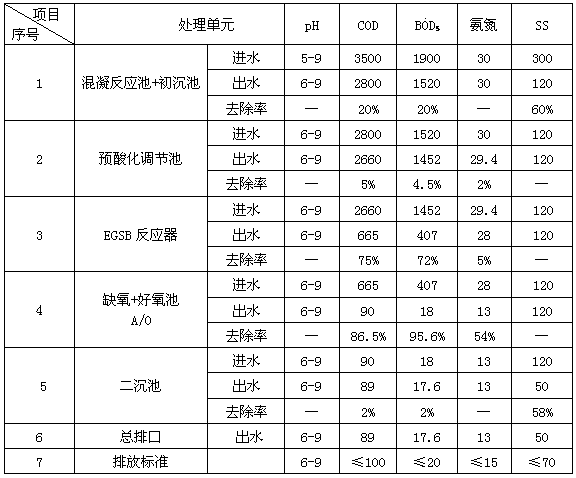

[0020] The production and domestic wastewater is discharged to the grid well through the pipeline, and the large particles are removed by the mechanical grid, and then enters the adjustment tank, and then the wastewater is lifted and pumped to the coagulation reaction tank, and large floc alum flowers are formed through the coagulation effect of dosing Then enter the primary sedimentation tank, remove most of the organic matter and SS by gravity sedimentation, and then discharge it into the pre-acidification adjustment tank. A thermometer is set in the pre-acidification adjustment tank to control the water temperature in the pre-acidification tank at 35-38 °C and PH at about 6.5-8.5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com