A Method of Determining the Angle of Casting Mold in Directional Solidification Casting

A technology of directional solidification and casting, which is applied in the field of determining the angle of casting molds in directional solidification casting, can solve the problems of crystal defects of directional solidification castings and large dispersion rate, and achieve the effect of eliminating circumferential temperature gradients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

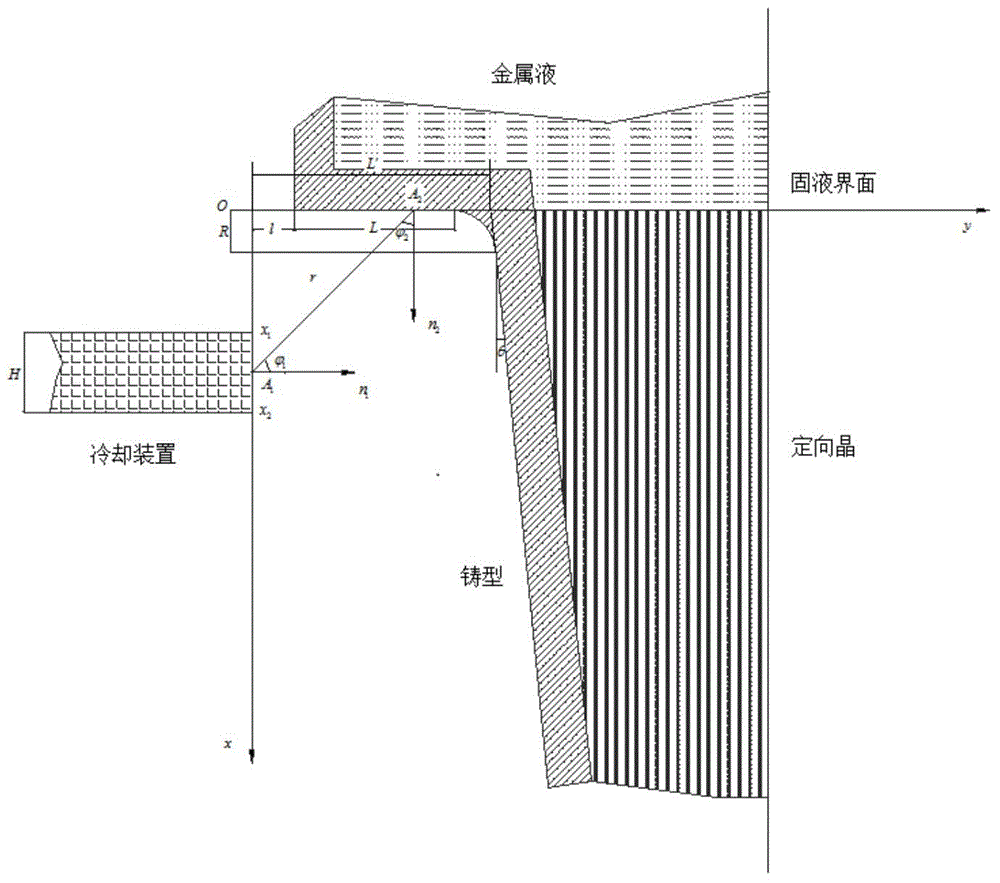

[0038] The present invention provides an example of determining the placement angle of a turbine blade mold of a certain type of gas turbine in a directional solidification furnace. As shown in Figure 1(a) and (b), it is the casting mold and blade wireframe diagram of a certain type of gas turbine blade,

[0039] According to the method provided in the present invention, utilize the program that provides in appendix A to carry out calculation, obtain the radiation angle coefficient change habitat diagram of the outer wall of the turbine blade at the root of the turbine blade shown in Fig. 3 (a), Fig. 3 (b) Fig. 3(c) shows the change habitat diagram of the radiation angle coefficient of the outer wall of the turbine blade airfoil casting mold.

[0040] According to Fig. 3(a), Fig. 3(b) and Fig. 3(c), the single-point radiation angle coefficients along the tenon root of the turbine blade, the joint between the tenon root and the airfoil, and the longitudinal direction of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com