Device for adjusting moving blades of axial flow fan

A technology of blade adjustment and axial flow wind, applied in the field of electric power, can solve problems such as large moment of inertia, low adjustment efficiency, complex processing technology, etc., achieve flexible transmission, stable angle, and solve the effects of inconsistent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

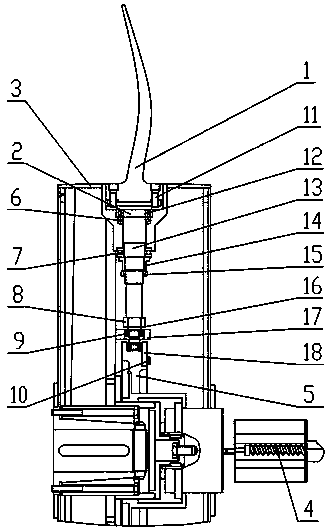

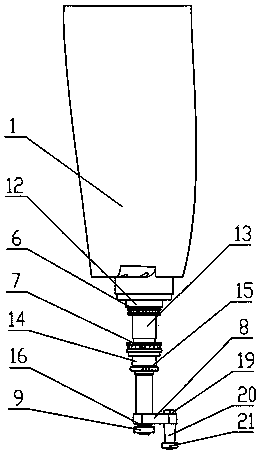

[0010] The invention will be further described below in conjunction with the accompanying drawings.

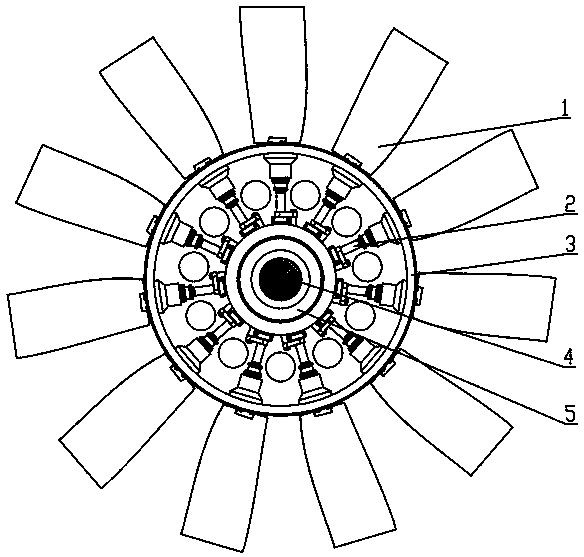

[0011] An axial-flow fan motor blade adjustment device, which is mainly composed of a moving blade (1), a transmission group (2), a wheel hub (3), a hydraulic transmission system (4), and a control panel (5), and is characterized in that the transmission group ( 2) Through the hub (3) upper blade installation shaft hole and the moving blade (1) are locked and connected with high-strength bolts (11); the transmission group (2) consists of a single row radial ball bearing (2) (12), a Thrust ball bearing (1) (6), one-way thrust ball bearing (2) (7), bearing pressure sleeve (14), round nut (15), connecting rod body (8), circlip for shaft (16) 1. The single-row radial ball bearing (1) (9) is set on the transmission shaft (13) in turn, and the single-row radial ball bearing (1) (9) falls in the support ring (17) and is placed on the connecting rod body (8) A rotating shaft (20) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com