Touch display structure

A touch display and touch module technology, which is applied to instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve problems such as easy mechanical interference and fragile surface glass, and achieve interference problems. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

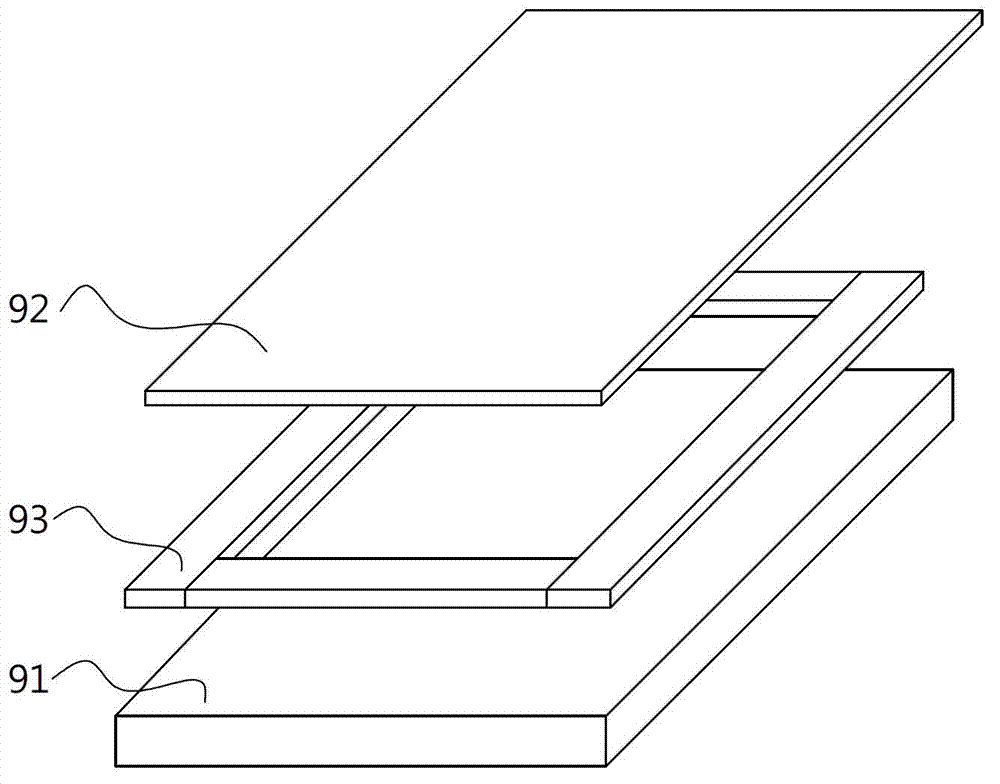

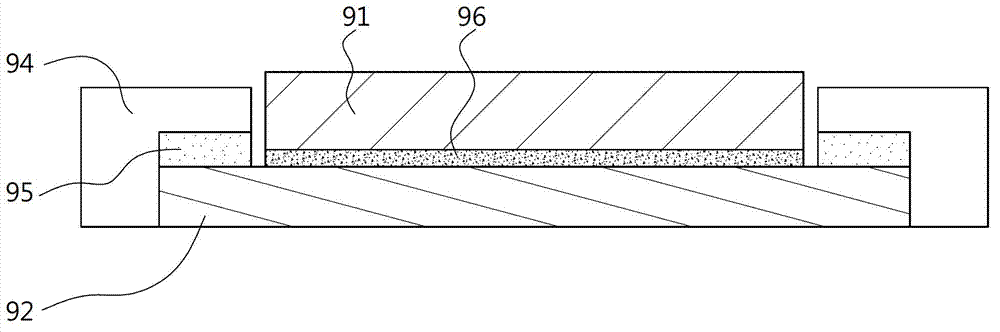

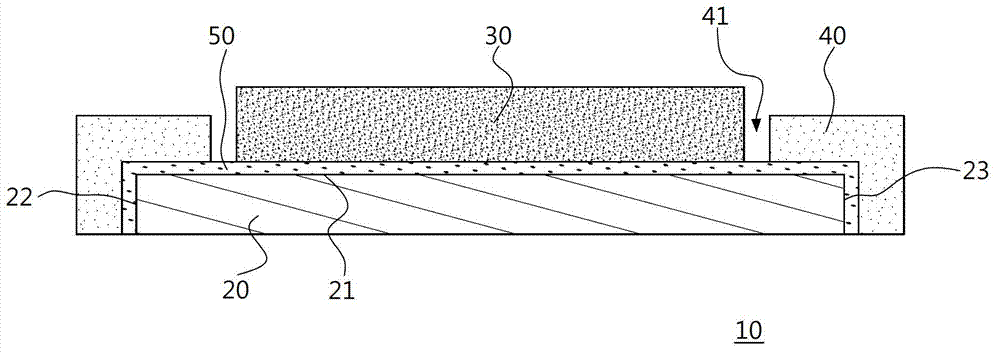

[0056] Please also see image 3 as shown, image 3 It is a schematic diagram of an embodiment of the touch display structure of the present invention, as shown in the figure: the touch display structure 10 in this embodiment at least includes a touch module 20, a display module 30 and a frame 40, wherein the touch module 20 has The joint surface 21 and at least two side surfaces 22, 23, and the two side surfaces 22, 23 are respectively adjacent to the joint surface 21 opposite to the left and right. In addition, the joint surface 21 and the two side surfaces 22, 23 of the touch module 20 are covered with One layer of adhesive layer 50 is a transparent and fluid adhesive substance.

[0057] The above-mentioned frame 40 is arranged on the periphery of the touch module 20 and bonded with the adhesive layer 50. In other words, the adhesive layer 50 is filled between the frame 40 and the touch module 20, and the touch module 20 is arranged on the frame 40 and the frame 40 has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com