Variable damping joint

A damping and joint technology, applied in the field of variable damping joints, can solve the problem that the workpiece can be adjusted in a limited position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

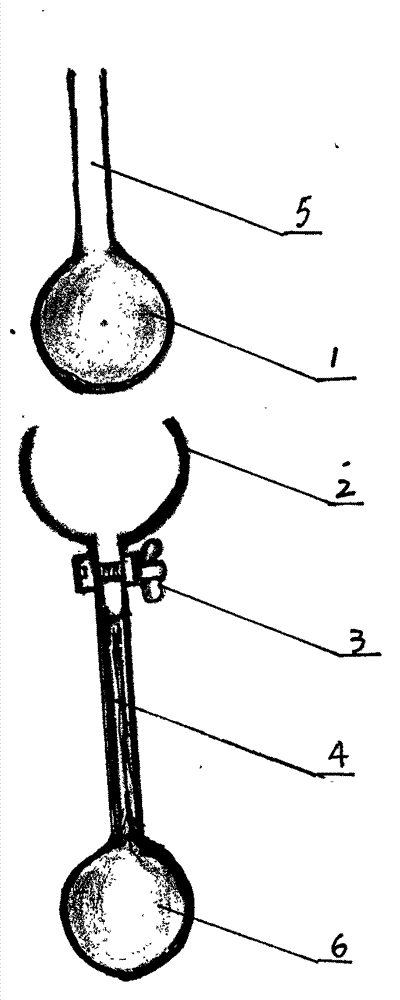

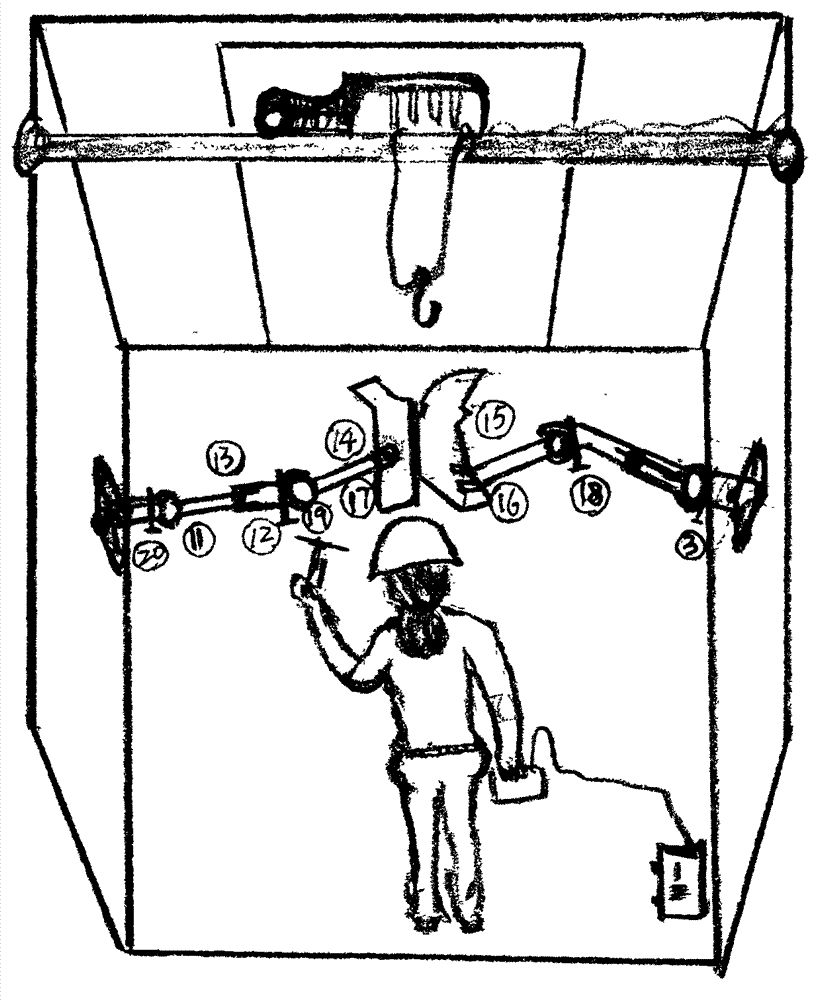

[0015] Such as figure 1 , the joint head 1 is a sphere with a certain radius, which is connected to the joint handle 5 at the back; the joint socket 2 is a spherical shell with a slightly smaller inner radius than the joint head 1, and 1 / 3 of the top is cut off, and it is divided into two from the middle; There can be two components with hemispherical shells manufactured in the same way. On the upper part of the joint handle 4, the root of the joint socket 2 is provided with a mounting hole for adjustment, and a bolt and a wing nut for convenient adjustment are inserted to form the adjustment device 3. The other end of the glenoid fossa 2 can also be the articular head 6.

[0016] Loosen the nut and insert the joint head into the joint socket. If it is required to be in a low damping state, the adjusting nut is loose, and the joint is in a relatively free sliding state; if it is required to be in a medium damping state, the adjusting nut is tightened, and the joint is in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com