Transport vehicle for automatic material transport system

A material transfer system and transfer vehicle technology, which is applied in the field of transfer vehicles in the automatic transfer system of silicon wafer boxes, can solve problems such as reducing transfer efficiency, and achieve the effects of improving transfer efficiency, increasing the number of loads, and improving transfer methods and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

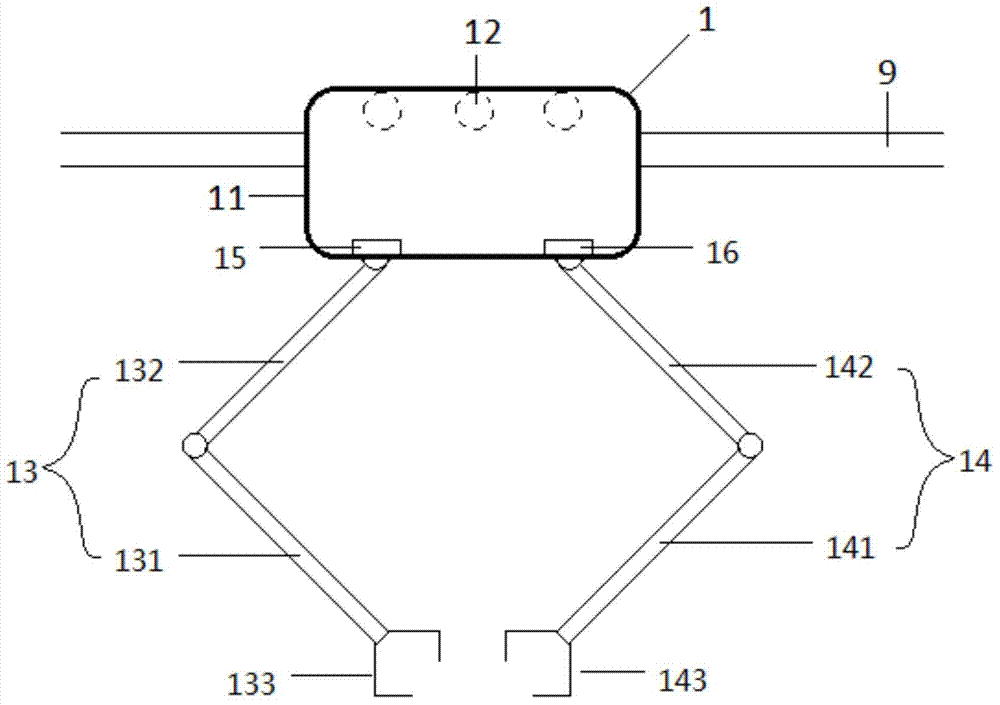

[0019] see figure 1 In this embodiment, the transport vehicle 1 used in the automated material transport system is suspended on the track 9 of the system, and it includes a vehicle body 11, a control unit (not shown) in the vehicle body, wheels 12 on the top of the vehicle body, and lifts at the bottom of the vehicle body device.

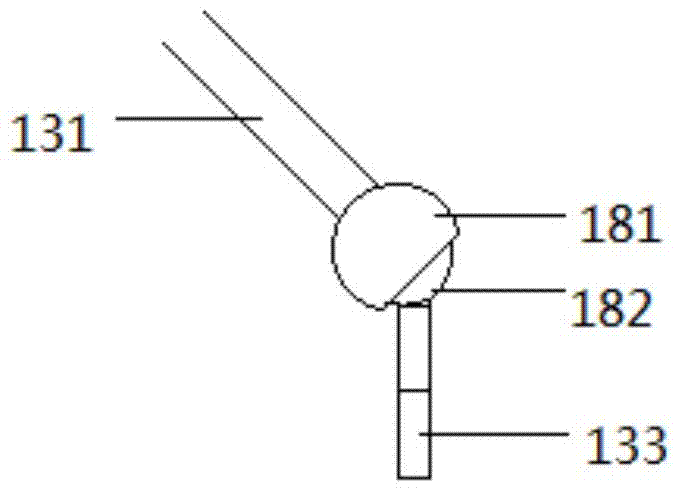

[0020] Wherein, the lifting device includes a first telescopic mechanical arm 13 and a second telescopic mechanical arm 14, and the first telescopic mechanical arm 13 and the second telescopic mechanical arm are respectively fixed on the front and rear sides of the vehicle body through the first turntable 15 and the second turntable 16. , and can be rotated horizontally. The first telescopic mechanical arm 13 is formed by a foldable connection between a first front straight arm 131 and a first rear straight arm 132. The end of the first front straight arm 131 is provided with a first picking and placing gripper 133 for picking and placing silicon w...

no. 2 example

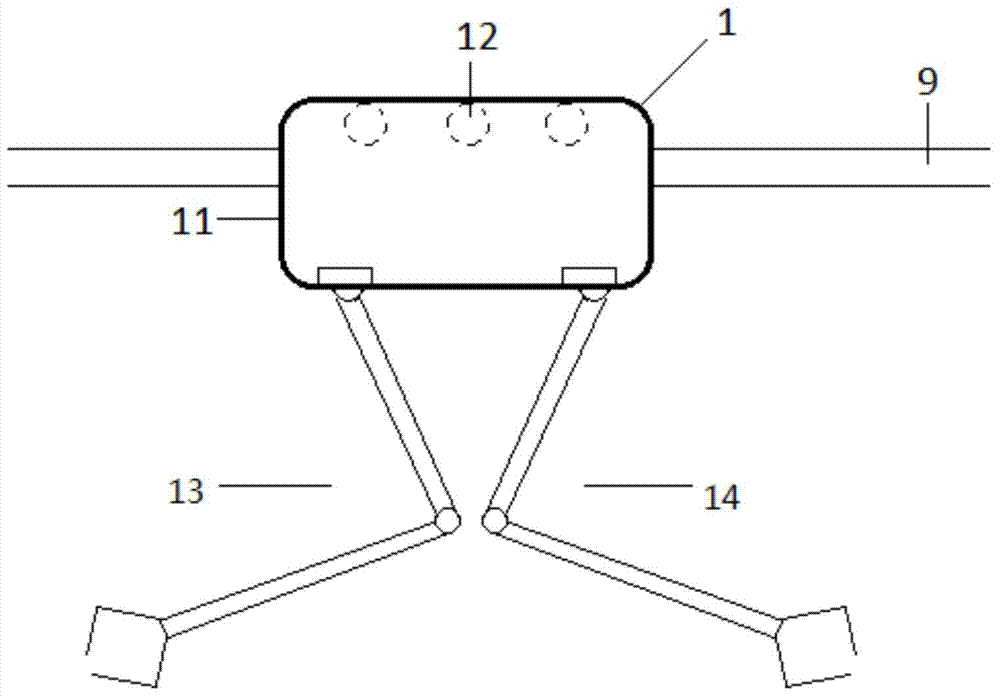

[0025] In this embodiment, the settings of the vehicle body, the control unit, the wheels, and the two telescopic mechanical arms are all the same figure 2 As shown in , but different from the first embodiment, the two telescopic mechanical arms are not fixed on two turntables respectively, but are fixed on a large turntable at the same time, and the large turntable is fixed on the bottom of the vehicle body and can rotate horizontally . Through such an arrangement, the front and rear positions of the two telescopic robotic arms can be exchanged, so that the silicon wafer box grabbed by the rear telescopic robotic arm can be transferred to the transport vehicle in front of the transport vehicle.

no. 3 example

[0027] In this embodiment, on the basis of the first embodiment, a large turntable is added, that is, the first turntable and the second turntable are fixed on a large turntable at the same time and can rotate horizontally, and the large turntable is fixed on the bottom of the vehicle body and can be rotated horizontally. Rotate horizontally. Through such a setting, the flexibility of the mechanical arm can be further increased, and the transport efficiency of the transport vehicle can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com