Actuating drive

一种驱动装置、传动装置的技术,应用在机电装置、电动组件、机壳/外罩/支承物等方向,能够解决复杂等问题,达到价格便宜、高运行可靠性和调节精度、准确轴向定位的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

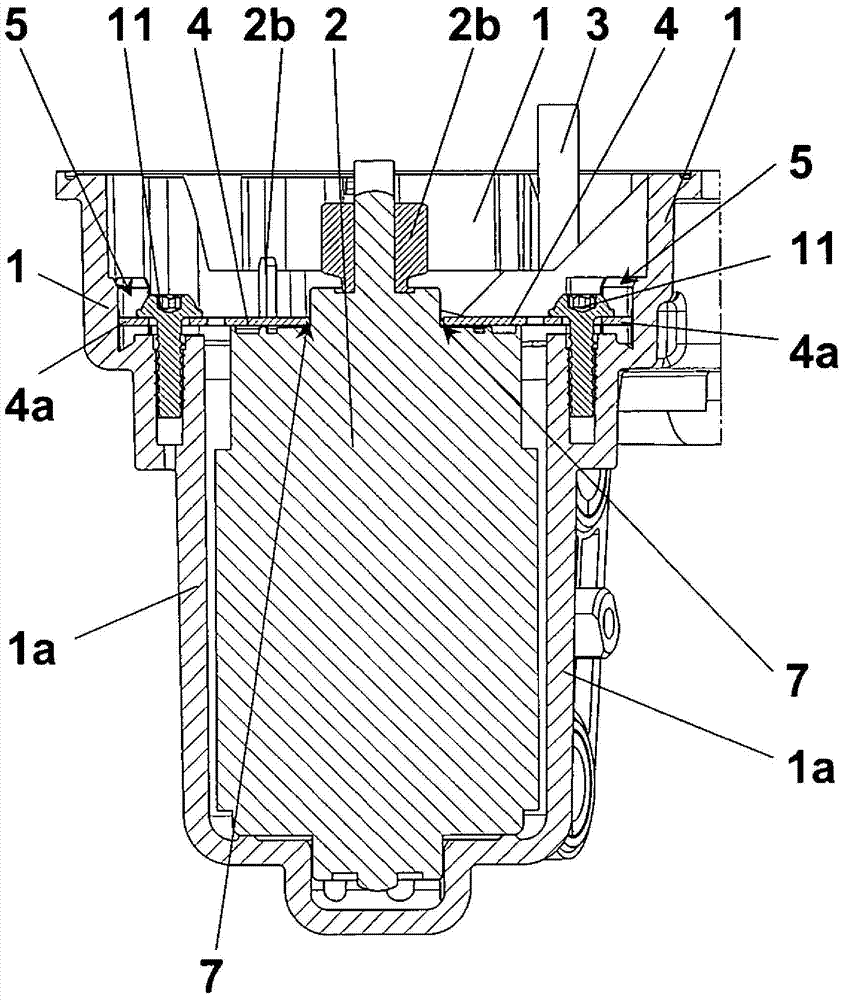

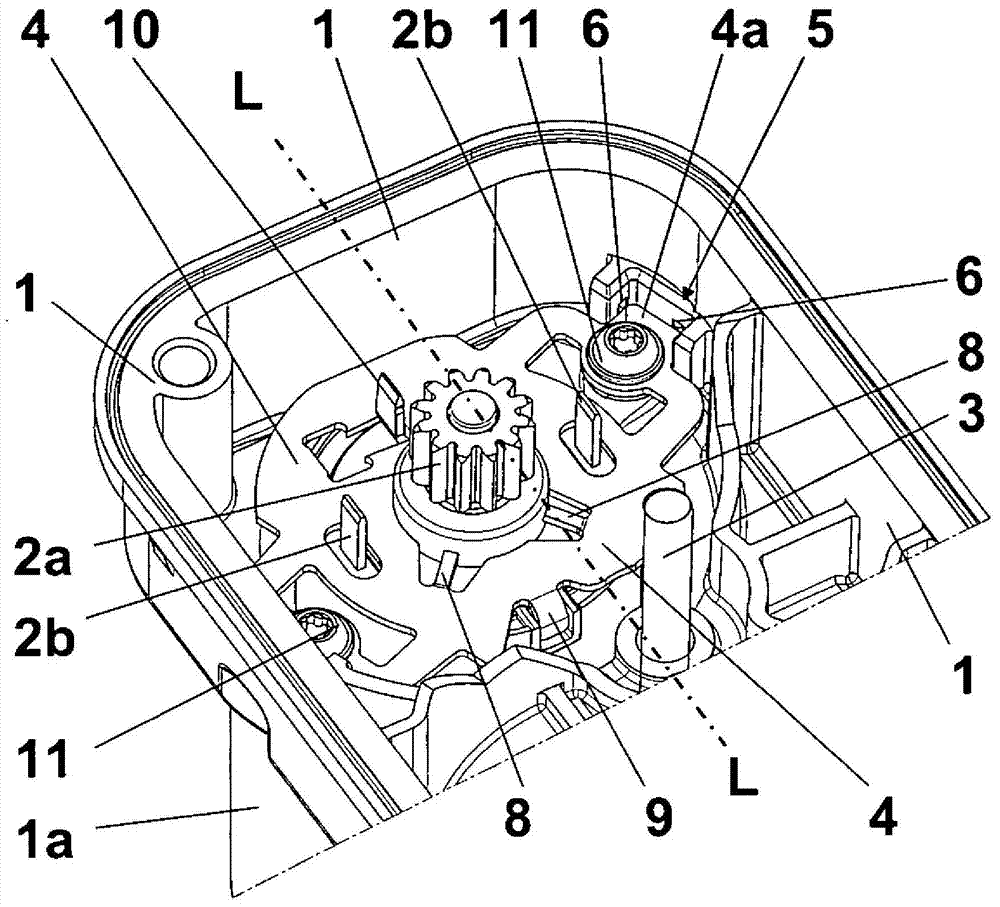

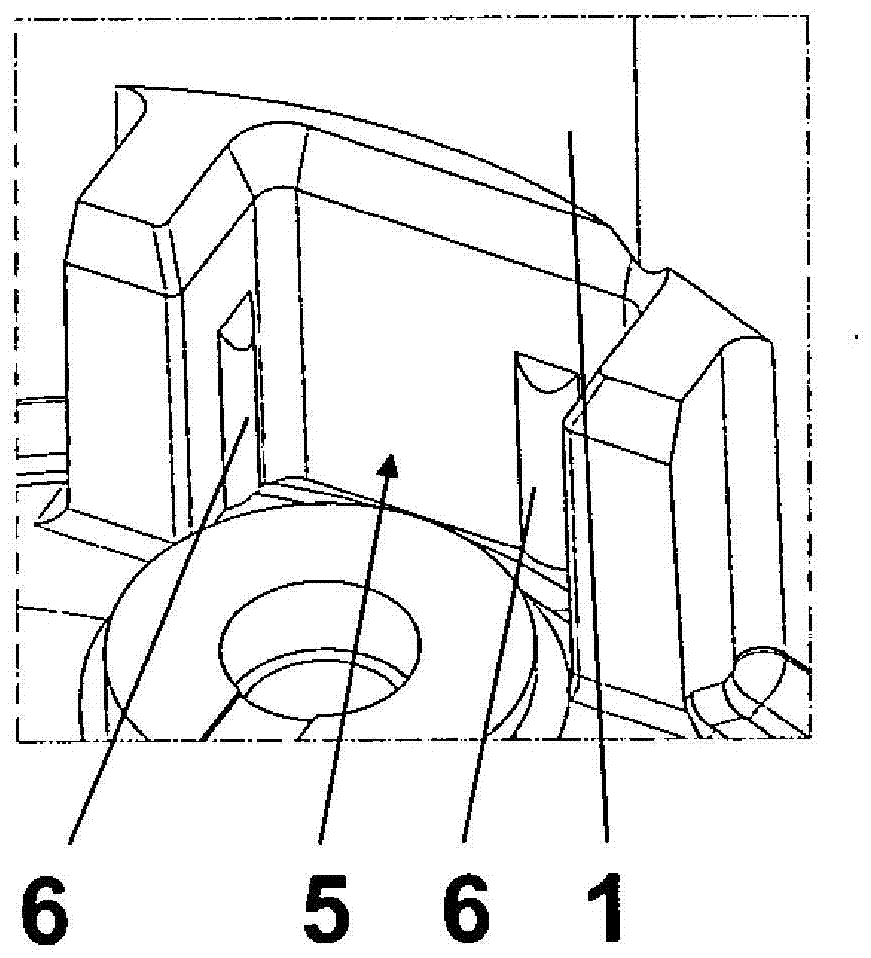

[0019] as from Figures 1 to 4 As can be seen in FIG. 1 , an adjusting drive comprises a housing 1 and (not shown) a cover and an output device, which is guided through the cover. The housing 1 and the cover are produced from plastic.

[0020] The housing 1 is substantially rectangular parallelepiped including a convex body 1a protruding from a bottom and having a pair of open sides disposed on the bottom. The convex body 1a is bottomed and thus part of the housing 1 and has a substantially circular cross-section on the inside. The convex body 1 a is arranged in an end region of the housing 1 with respect to the longitudinal axis L of the cuboid-shaped part and is dimensioned to accommodate a radially symmetrical electric motor 2 . The electric motor is fixed in the male body 1a and has an output shaft at its upper end protruding into the cuboid part of the housing 1 with a pinion 2a as part of a reduction gear. The upper end is formed, for example, as a motor shoulder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com