Coal sample preparing system

A sample preparation system and coal technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve problems such as high labor intensity, system bias, and the impact on the health of operators, so as to reduce labor intensity and reduce intervention degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The core of the invention is to disclose a coal sample preparation system to achieve the purpose of improving and reducing the labor intensity of workers.

[0034] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

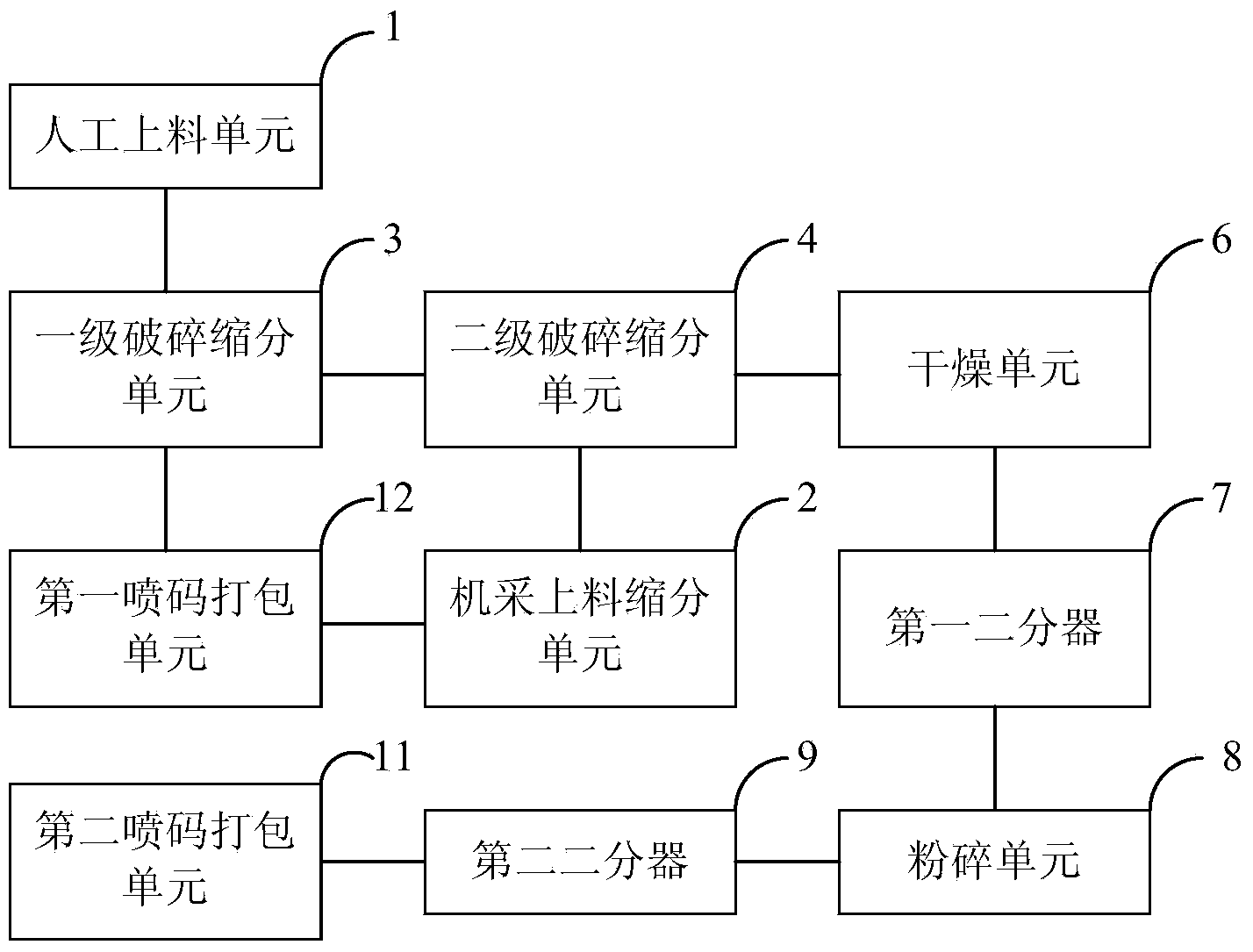

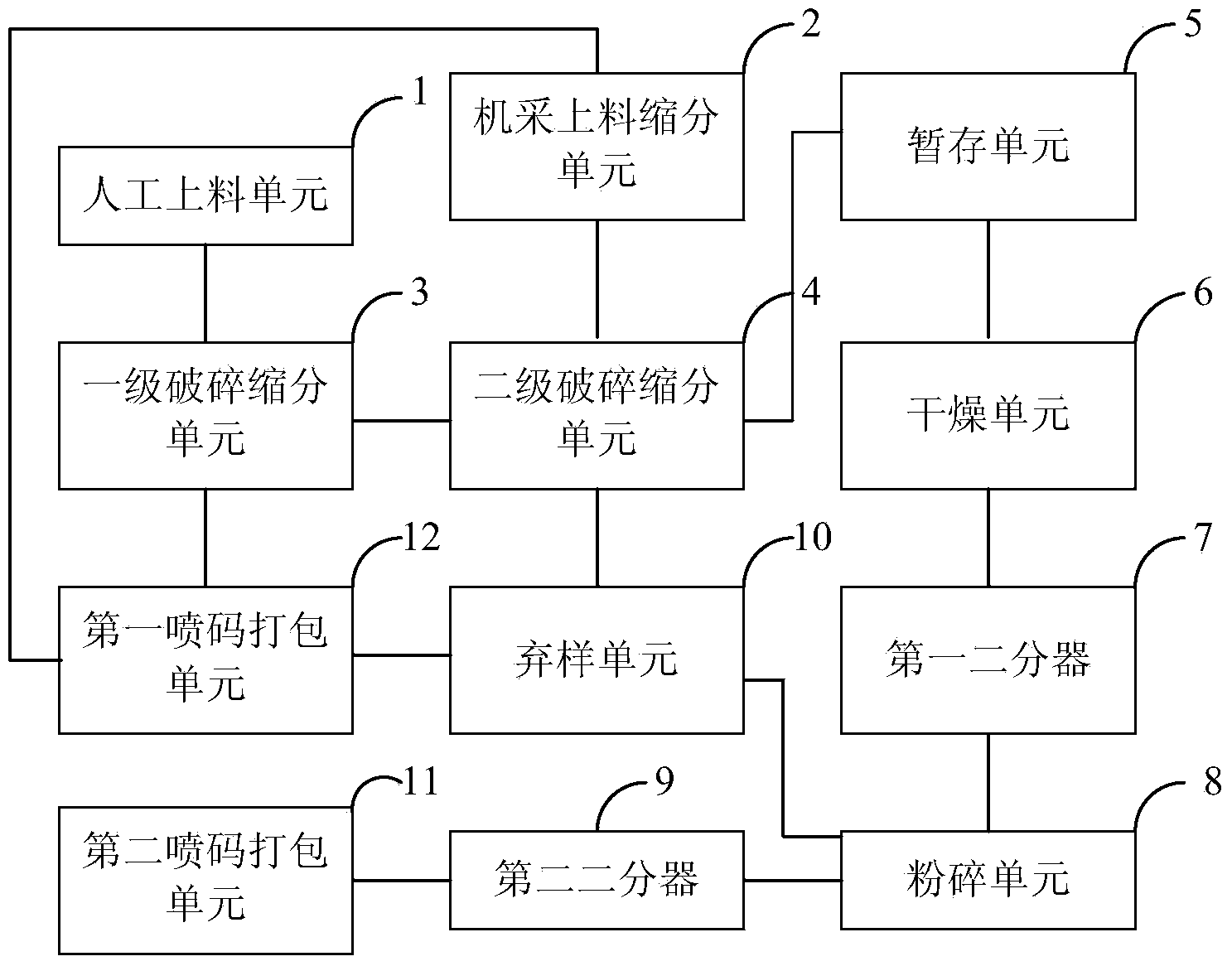

[0035] The coal sample preparation system includes a control unit, a manual feeding unit 1, a primary crushing and dividing unit 3, a machine mining feeding and dividing unit 2, a secondary crushing and dividing unit 4, a drying unit 6, and a first splitter 7, crushing unit 8, the second splitter 9, the first packaging inkjet unit 12 and the second packaging inkjet unit 11, wherein:

[0036] The control unit is used to determine the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com