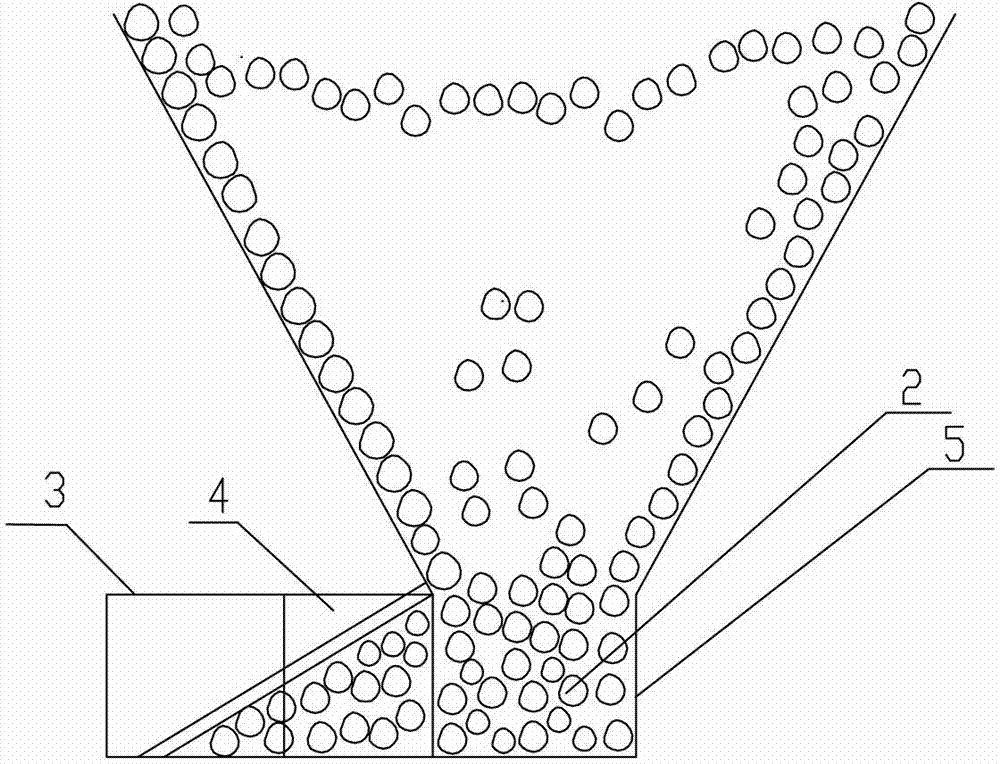

Non-pillar sublevel caving mining method for discharging ores from side part of electric rake roadway

A technology of electric raking roadway and sub-caving, which is applied in surface mining, underground mining, special mining, etc., can solve the problem of high one-time investment, and achieve the effect of reducing mining cost and high rock drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Taking a certain mine as an example, the segmental connection roadway described in the present invention has a height × width of 3 m × 3m; the mining approach height × width is 3 m × 2m; The height × width of the mine chute is 2 × 2m; the height × width of the upper wall exhaust roadway is 0.8 m × 1.5m or 1 m × 1.5m. The size of the approach can be reduced, but considering that if the size of the mining approach is small, it is very unfavorable to release the ore that collapses in the approach, so the mining approach still chooses a large section. With this method of mining, the amount of mining and cutting work will increase relatively, but the increased electric rake roadway and the ore-sliding horizontal roadway connected in the middle will bring a considerable amount of ore, which offsets the cost of mining and cutting. At the same time, the self-propelled rubber-tyred front-end loader, which is expensive in price, operation and maintenance, is replaced by a cheap a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com