Adapting piece of assembling door

A door connector and connecting edge technology, applied in the direction of door leaf, etc., can solve the problems of easy corrosion of solder joints, time-consuming and laborious, and easy deformation of soldered parts when heated, and achieve the effects of good quality, accurate overall structure and size, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

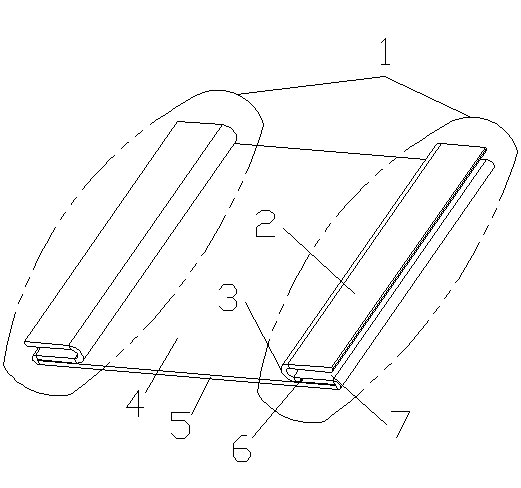

[0010] Depend on figure 1 The assembled door connector shown includes a board body 5, the two board surfaces of the board body 5 are the front side 4 and the back side respectively, and a bending part 1 is respectively set on the left and right sides of the front side 4 of the board body 5, and the folding part 1 is arranged on the front side of the board body 5. The bending part 1 is provided with a clamping mouth 7, and the bending part 1 includes a laminated bending edge 6 that fits on the board surface - the front surface 4, and a clamping edge 2 arranged parallel to the laminated bending edge 6 at intervals. And the connection edge 3 that is connected between the lamination bending edge 6 and the clamping edge 2, the described jaw 7 that is formed by the lamination bending edge 6, the connection edge 3 and the clamping edge 2 is a U-shaped mouth, and the lamination The end of the bending edge 6 located at the jaw 7 is flush with the end of the clamping edge 2 located at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com