Waste alkaline water recycling system in mercerizing machine weak alkali pool

A technology of waste alkaline water and light alkali pool, which is applied in the field of waste alkaline water recycling system in the light alkali pool of mercerizing machine, can solve the problems of restricting enterprise development, large water volume, increasing sewage treatment cost, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples facilitate a better understanding of the present invention, but do not limit the present invention.

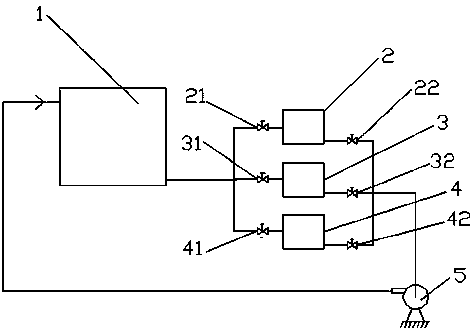

[0020] Such as figure 1 As shown, the waste alkaline water recycling system in the light alkali pool of the mercerizing machine of the present invention comprises a light alkali pool 1, a first sedimentation tank 2, a second sedimentation tank 3, a third sedimentation tank 4 and a pump 5, the first sedimentation tank 2, The second sedimentation tank 3 and the third sedimentation tank 4 are placed side by side. The outlet of the light alkali tank 1 is connected with the inlets of the first sedimentation tank 2, the second sedimentation tank 3 and the third sedimentation tank 4 respectively, wherein a second A sedimentation tank upstream switch 21, a second sedimentation tank upstream switch 31 is arranged between the outlet of the light alkali tank 1 and the inlet of the second sedimentation tank 3, and a second sedimentation tank upstream swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com