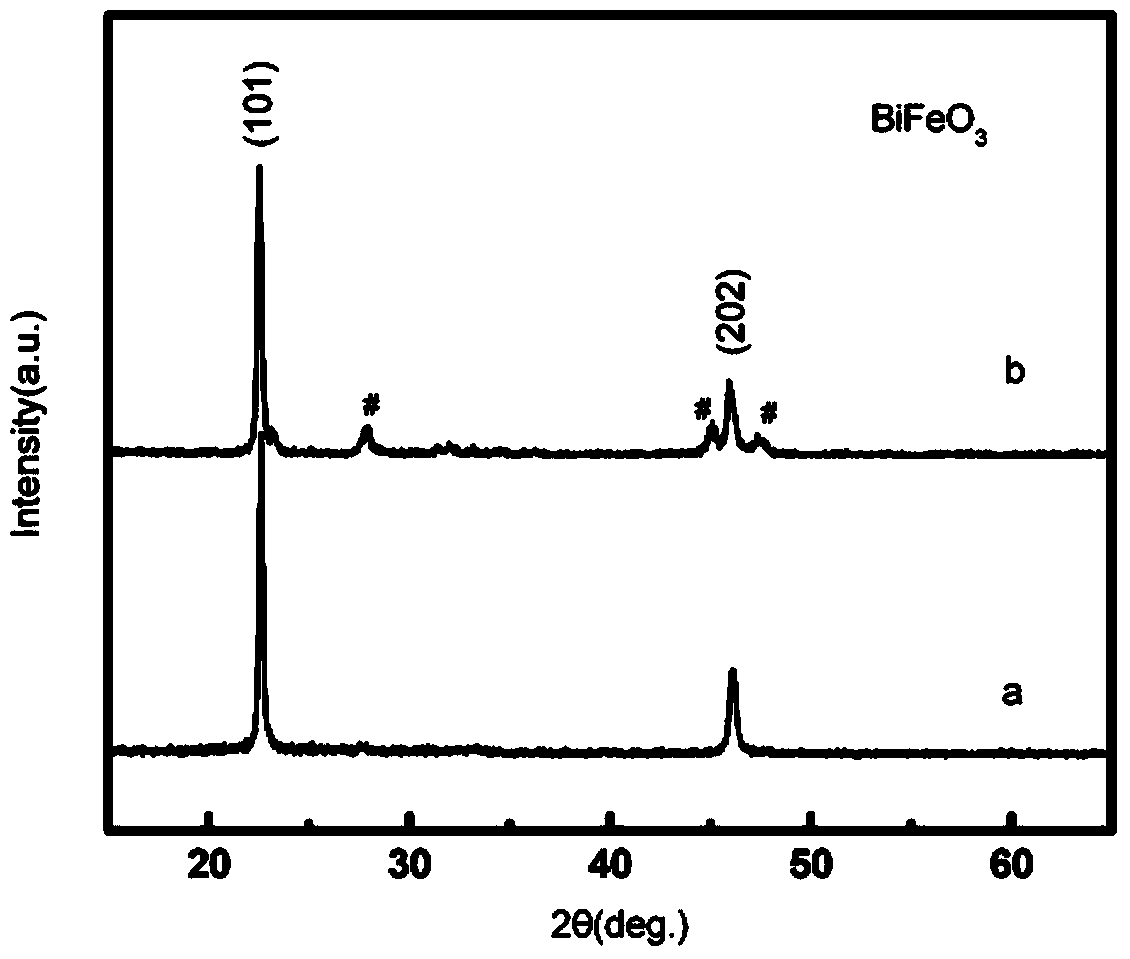

Multilayer homogeneous growth bismuth ferrite thin-film material and preparation method thereof

A thin film material, bismuth ferrite technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems of low structural density, reduced ferroelectric performance, limited application prospects, etc. And the effect of surface property optimization, surface property improvement, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] In this embodiment, the specific preparation steps of the multilayer homogeneously grown bismuth ferrite film material are as follows:

[0035] a. The lanthanum nickelate thin film was first prepared at room temperature by magnetron sputtering;

[0036] b, then annealing is carried out in a rapid thermal annealing furnace, the annealing temperature is 650°C, the sputtering chamber pressure is 2.4pa, the sputtering power is 80W, the sputtering time is 40 minutes, and the ratio of argon and oxygen is 20:0 to obtain nickel acid Lanthanum thin film electrode material, the resistance meets the electrode requirements;

[0037] c. 99% Bi 2 o 3 and 99% Fe 2 o 3 Weigh and pour it into a ball mill jar with a molar ratio of 1.05:1, pour in an appropriate amount of deionized water, and mill it in a ball mill for 20 hours, take it out and dry it, pour it into a mortar, and grind it for 15-20 minutes.

[0038] d, and then mix the Bi 2 o 3 and Fe 2 o 3 The powder was pre-fired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com