Lifting roller way machine

A roller table machine and roller table technology, applied in the direction of roller table, conveyor objects, transportation and packaging, can solve the problems of complex chain lifting or lowering mechanism, complex electrical control, inaccurate positioning, etc. Simple electrical control and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

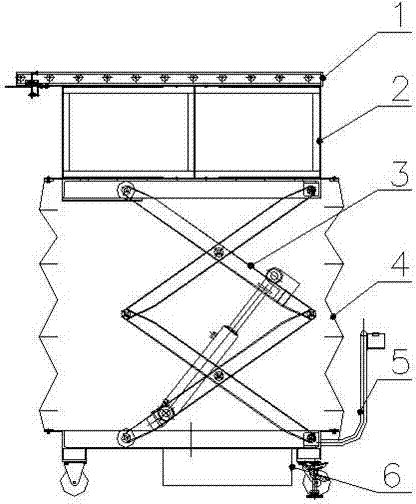

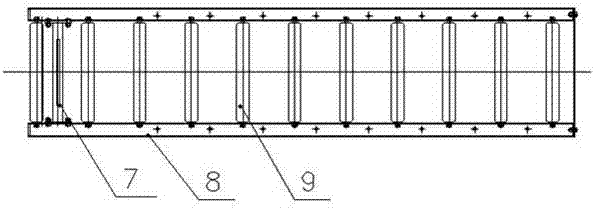

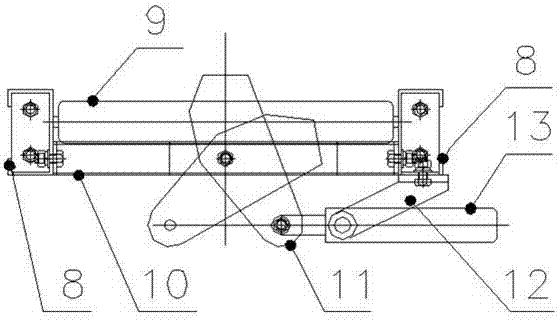

[0022] Such as Figure 1-Figure 7 As shown, the lifting roller table machine includes a roller table 1, a frame body 2, a four-bar connection mechanism 3, a protective cover 4, a trolley 5 and a power unit 6, and the above-mentioned roller table 1 can be an unpowered roller according to the requirements of use. The road can also be a powered roller table. The present invention is a non-powered roller table. The roller table 1 is connected with the four-bar connection mechanism 3 through the frame body 2, and the four-bar connection mechanism 3 is installed on the trolley 5, thereby achieving The lifting roller machine can move, the lower part of the trolley 5 is equipped with a power unit 6, in order to prevent the four-bar connection mechanism 3 and the power unit 6 from being eroded by water, a protective device is provided between the frame body 2 and the trolley 5. Cover 4, to achieve the purpose of not being eroded by water when cleaning the lifting roller table machine w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com