Workpiece conveying device for aluminum plate spraying room

A transmission device and spraying room technology, which is applied in the field of workpiece transmission device in the aluminum plate spraying room, can solve the problems of affecting the processing process and processing effect, flexibly changing the way of placing workpieces, and low processing efficiency, so as to facilitate the placement of workpieces and improve spraying Efficiency, convenient spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

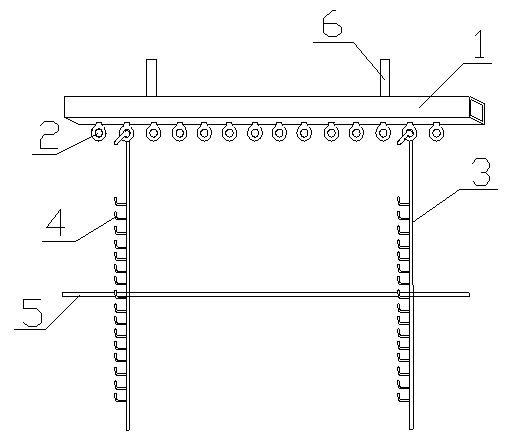

[0011] Such as figure 1 As shown, the aluminum plate spraying room workpiece transmission device provided by the present invention includes a transmission frame 1, the lower surface of the transmission frame 1 is uniformly welded with a hanging ring 2, and two hanging rings 2 are hung on the two ends of the transmission frame 1. The same hanger 3, the hanger 3 is evenly welded with a hook 4, a horizontal bar 5 is placed on the two hooks 4 of the same height, and two identical bars are welded on the upper surface of the transmission rack 1. The chain 6, the transmission frame 1 is a hollow cuboid structure.

[0012] The working principle of the present invention is that at first the transmission frame 1 is fixed on the assembly line device by two chains 6, and when the workpiece size is larger, it is directly hung on the hanging ring 2 for transmission and spraying; when the workpiece size is smaller, the Two identical hanging racks 3 are hung at both ends of the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com