Continuous lifting roller bed

A technology of roller table and lifting bracket, which is applied in the field of conveying line, can solve the problems of heavy financial pressure, achieve the effect of ingenious design concept and meet the needs of material transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

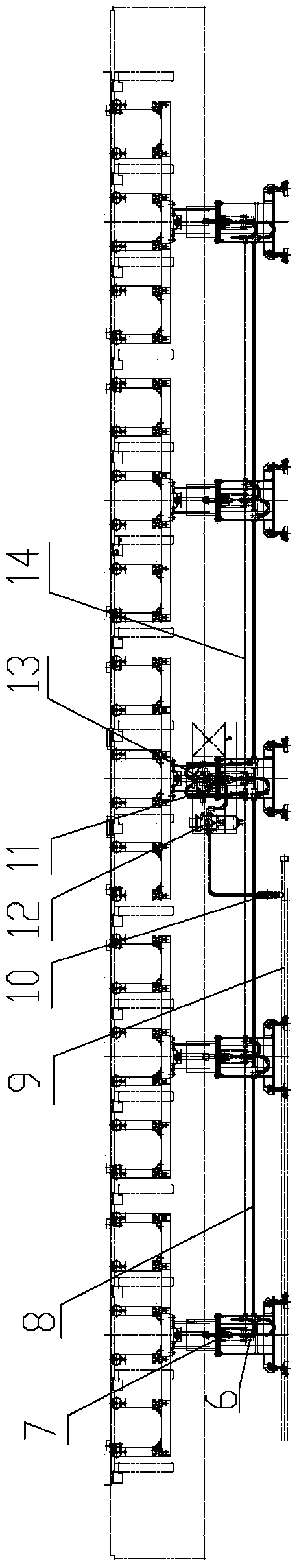

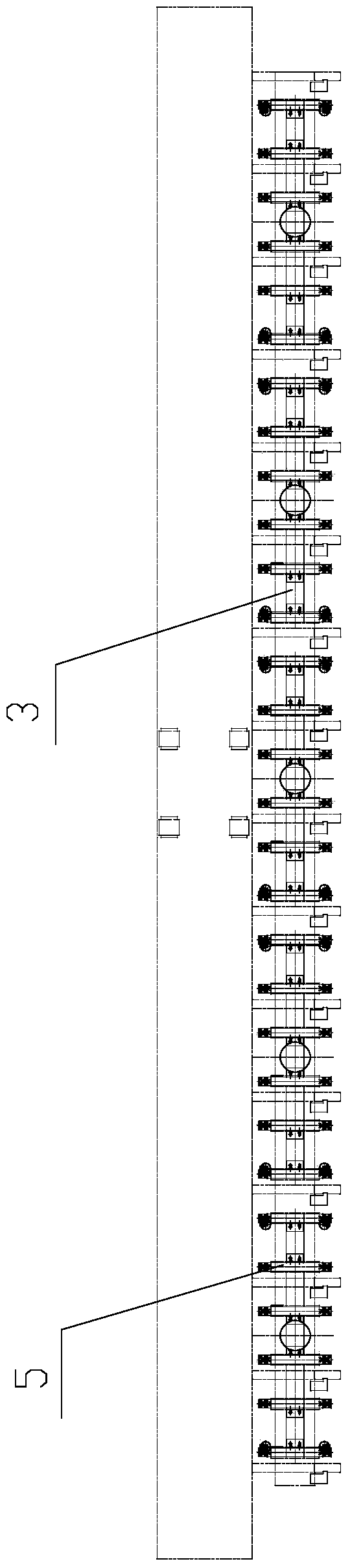

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Figure 1~3 Among them, including lifting bracket 1, smooth motion lifting cylinder 2, top frame 3, rotary guide wheel 4, unpowered roller 5, elbow 6, speed control valve 7, gas pipeline 8, main air pipe 9, ball valve 10, Quick change joint 11, filter pressure reducing valve 12, through solenoid valve 13, return air pipeline 14, etc.

[0013] like Figure 1~3 As shown, the present invention is a continuous lifting roller table, comprising several lifting brackets 1 equidistantly arranged in rows, each lifting bracket 1 is equipped with a smooth motion lifting cylinder 2, and each smooth motion lifting cylinder 2 The gas ports are all connected to the gas transmission pipeline 8, and the gas outlets are all connected to the return gas pipeline 14; the top of the lifting bracket 1 is fixed with a piston sleeve by bolts, and the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com