A plunger pump anti-gasification liquid medium gasification device

A liquid medium and gasification device technology, applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, pressure vessels, etc., can solve the problems of failing to meet the requirements of liquid carbon dioxide injection, unstable technology, and plunger pumps that cannot operate and other problems to achieve the effect of overcoming the difficulties in the gasification process, eliminating heat, and ensuring reliable equipment support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

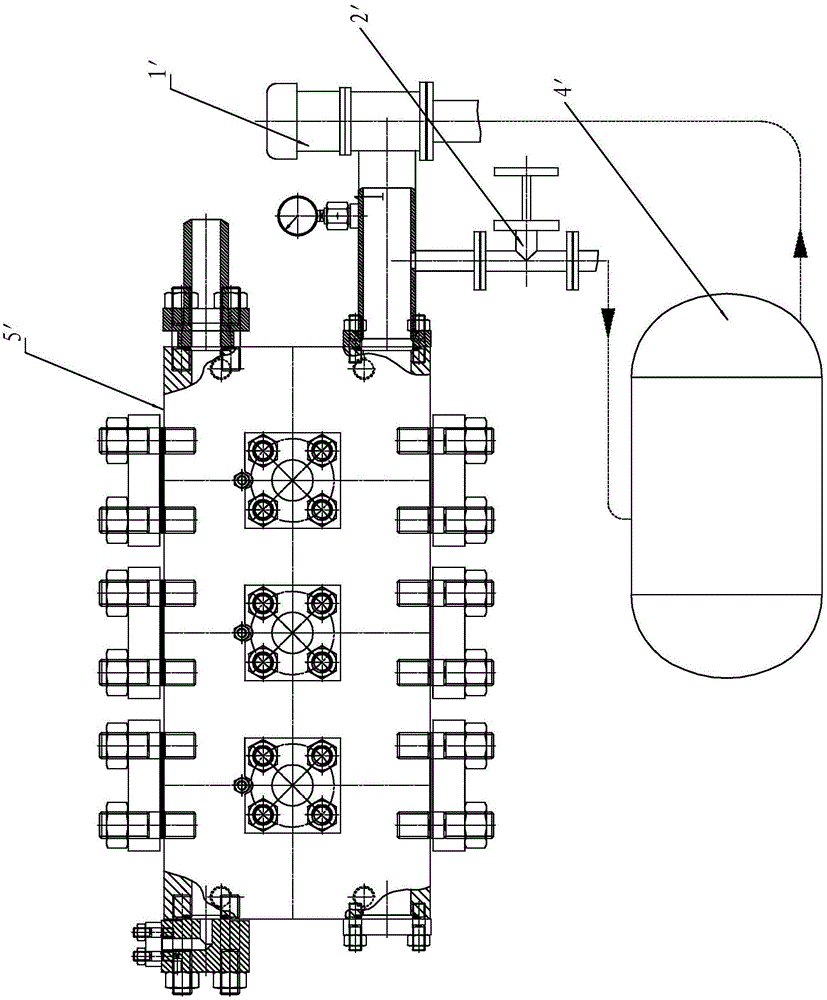

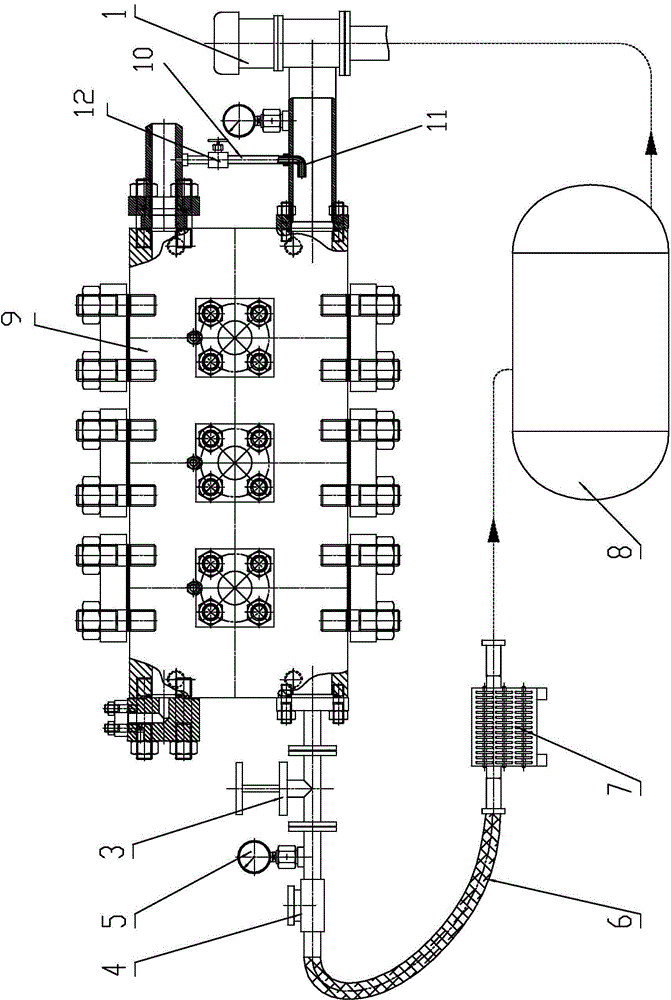

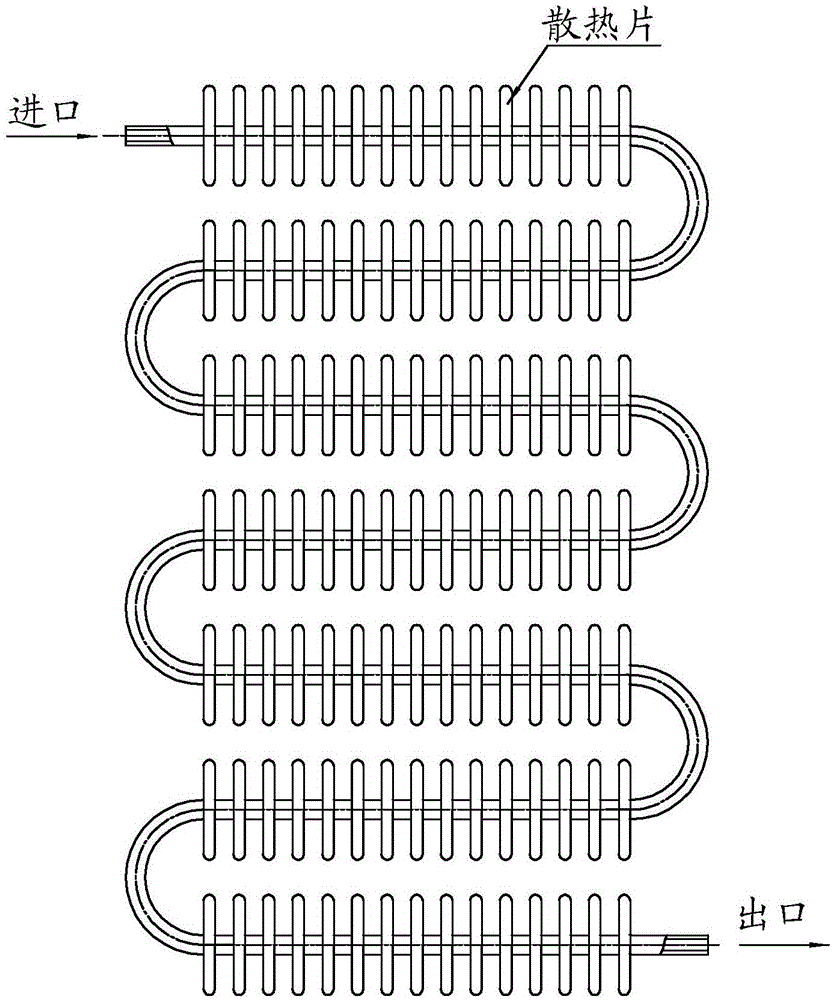

[0016] In this embodiment, the device of the present invention is described in detail by taking the transportation of liquid carbon dioxide as an example, as figure 1 The plunger pump anti-gasification liquid medium vaporization device shown includes an adjustment manifold for adjusting the return flow rate and constant pressure and temperature in the inlet chamber of the plunger pump. The adjustment manifold includes a throttle valve 3, a stop Return valve 4, pressure gauge 5, return line 6 and heat exchange supercharger 7, wherein the inlet of throttle valve 3 is set at the channel of the plunger pump 9 liquid inlet, and can also be set to be connected with the plunger pump 9 liquid inlet The outlet of the throttle valve 3 communicates with the inlet of the check valve 4, the outlet of the check valve 4 communicates with the liquid inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com