Gas-water-slag separating buffer type gas spraying orifice preventive device

An anti-gas and gas water slag technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of no gas water slag, gas exceeding the limit, and release in the roadway, so as to reduce labor intensity, improve safety, Guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

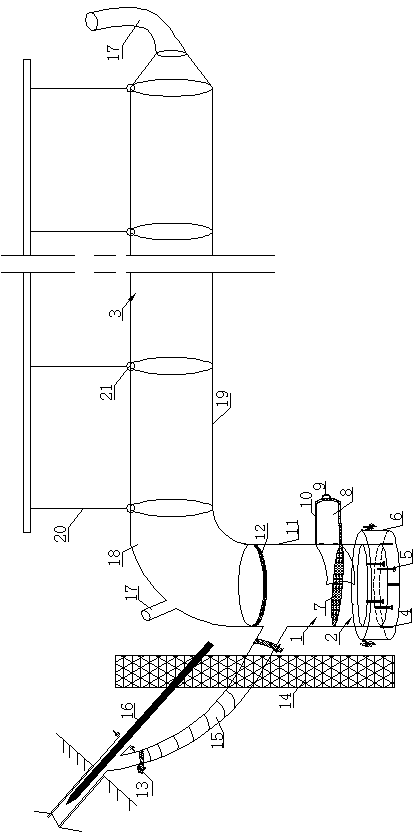

[0013] As shown in the figure, a gas-water slag separation buffer type anti-gas nozzle device of the present invention is mainly composed of a gas coal dust collector 1, a gas extraction water gas separator 2 and a buffer type gas drainage device 3. Select the drilling position according to the design, and install two-way at the drill hole, one through the drill pipe 16, and the other through the connection hose 15 to connect the gas coal dust collector 11. Put the gas and coal dust collector 11 into the automatic overflow tank 6, and use the device fixing bolt 5 to block the gas and coal dust collector 11, so that the gas and coal dust collector 11 is tightly fixed in the automatic overflow tank 6. The slag-water separation net 7 is installed in the collector 11 body, and the slag-water separation net 7 has a certain inclination angle, and the inclined slag removal hinge door 8 is conducive to the cleaning of coal dust. The support bolt 4 of the box supports the gas and coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com