Longitudinal sliding type shell crushing mechanism

A sliding and vertical technology, applied in the field of food processing, can solve the problems of low processing efficiency and cumbersome operation, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

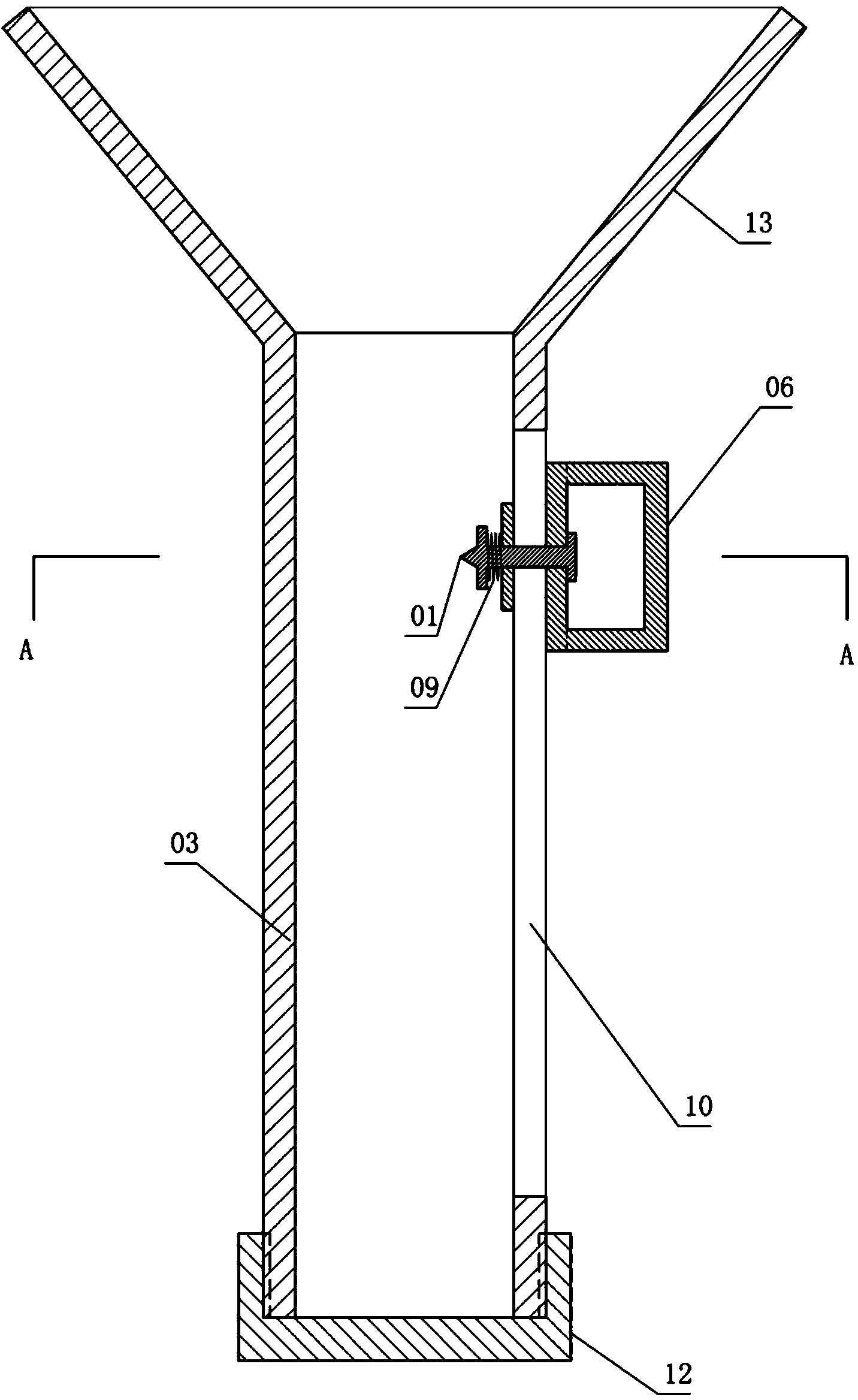

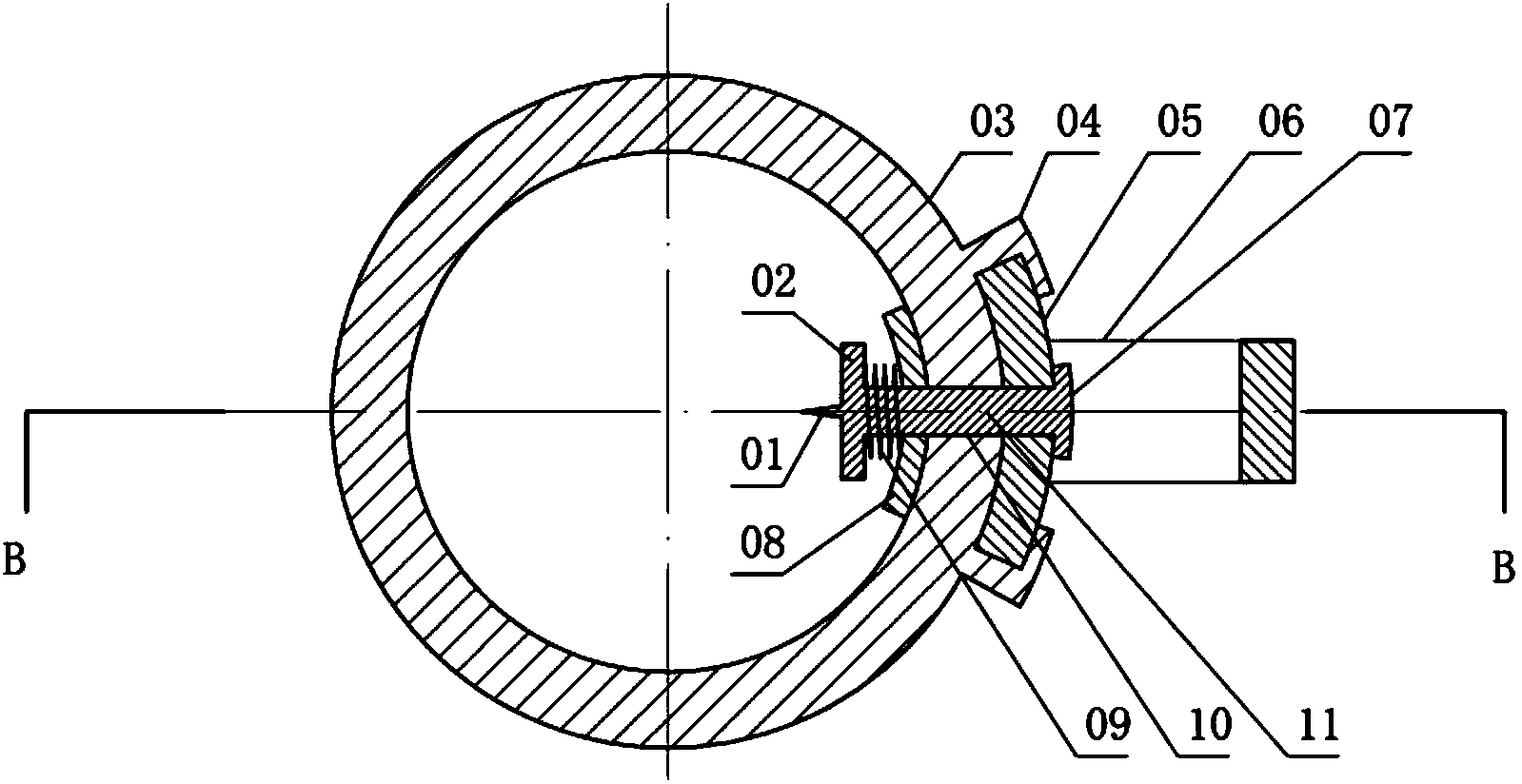

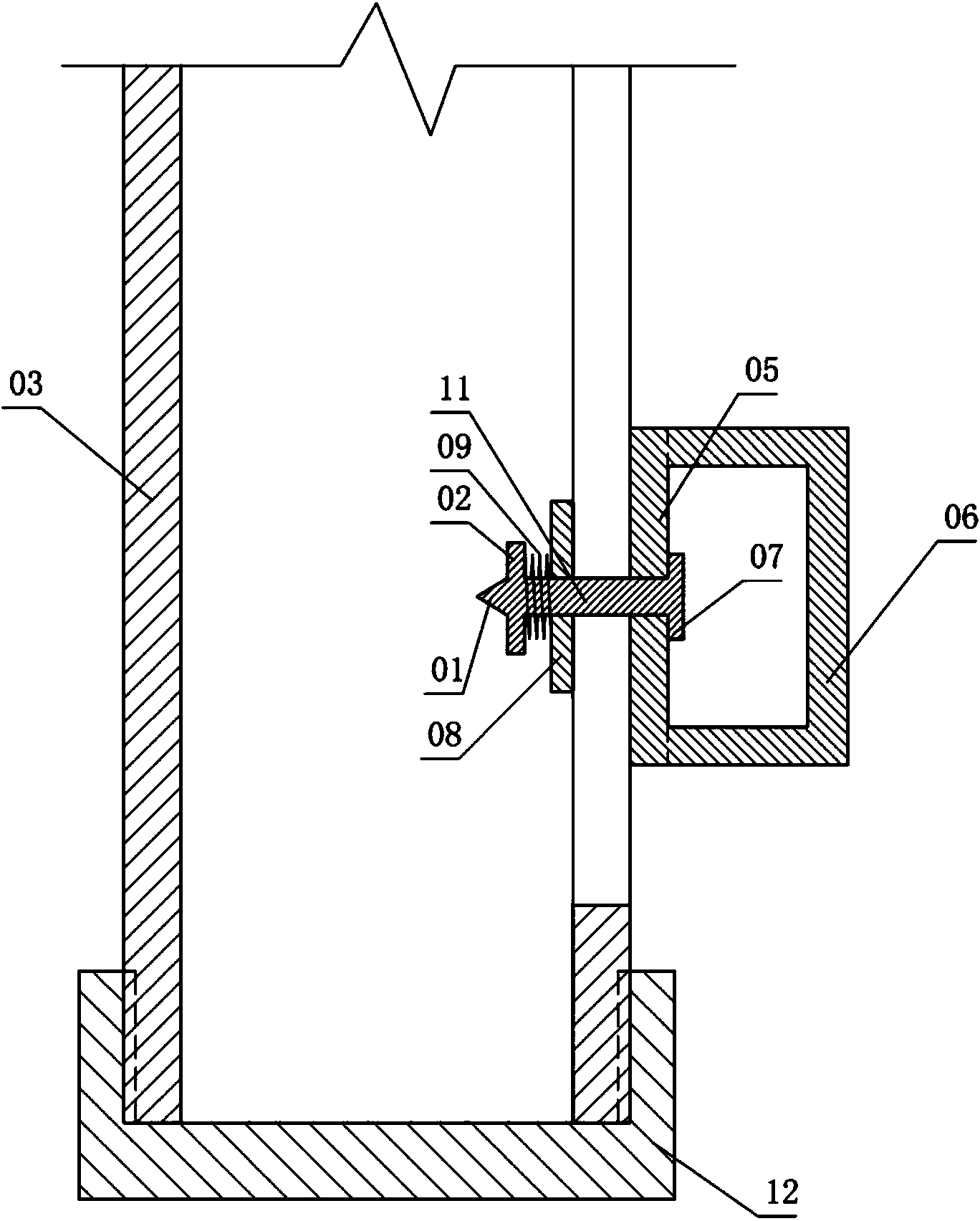

[0016] Longitudinal sliding shell crushing mechanism consists of cutting edge 01, limit piece 02, cylinder body 03, limit strip 04, outer slide piece 05, handle 06, non-return piece 07, inner slide piece 08, spring 09, sliding piece Groove 10, knife handle 11, bottom cover 12 and hopper 13 constitute.

[0017] The cylinder 03 is a cylinder with a longitudinal chute 10 on the side wall. The upper end of the cylinder 03 is a funnel-shaped hopper 13 integrated with the cylinder 03. The lower end of the chute 10 is screwed to the cylinder 03. The disc-shaped bottom cover 12.

[0018] On the outer wall of the cylinder 03, located on the left and right sides of the chute 10, there are respectively a longitudinal limit strip 04 integral with the cylinder 03. The planar shape of each limit strip 04 is L-shaped. The inner wall of the bit strip 04 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com