Mining expansion type anti-shock single hydraulic support

A hydraulic support and single-piece technology, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of insufficient dynamic response time of the overflow valve and too late to open the overflow valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

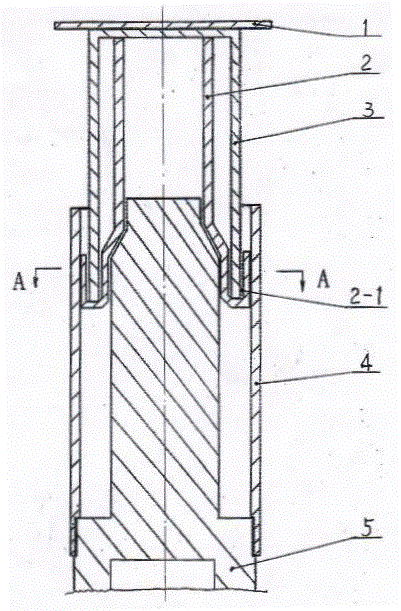

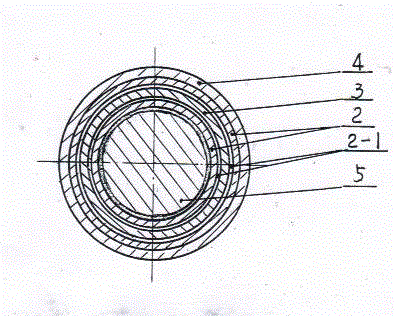

[0010] Examples, see attached figure 1 , 2 , the expansion-diameter anti-shock single hydraulic support for mining is to make the upper body of the single hydraulic support 5 into the shape of a variable-diameter boss, and install an insert with an expanding sleeve on the variable-diameter upper boss of the single hydraulic support 5 The expansion tube 2 of groove 2-1 coincides with the single hydraulic support 5 in the same shape, and the expansion sleeve insertion groove 2-1 is formed by turning over the trumpet-shaped opening at the lower end of the expansion tube 2, and the lower end of the single hydraulic support 5 The outer diameter and the outer diameter of the upper end form a shoulder, the single hydraulic support 5 is fixedly connected with the anti-tilt sleeve 4 by threads, the anti-tilt sleeve 4 is set on the periphery of the expansion sleeve insertion groove 2-1, 2-1 inserts a diameter-expanding sleeve 3 with a closed upper end, the inner closed end of the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com