Water-based drilling fluid waste solid-liquid separation equipment and method

A technology of water-based drilling fluid and solid-liquid separation, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficulties and increased final treatment, and achieve treatment costs The effect of low cost, saving floor space and mild treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

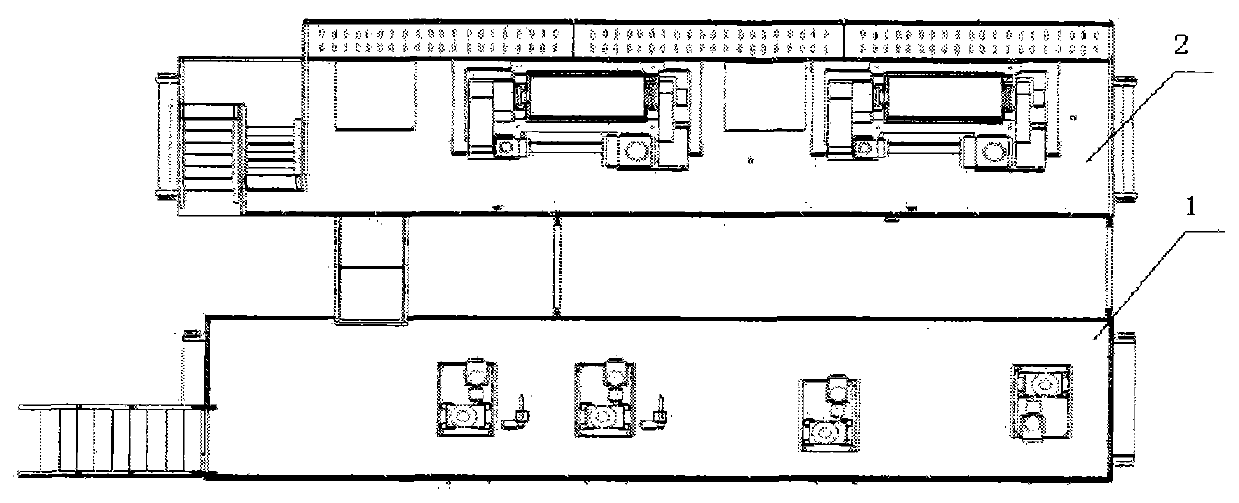

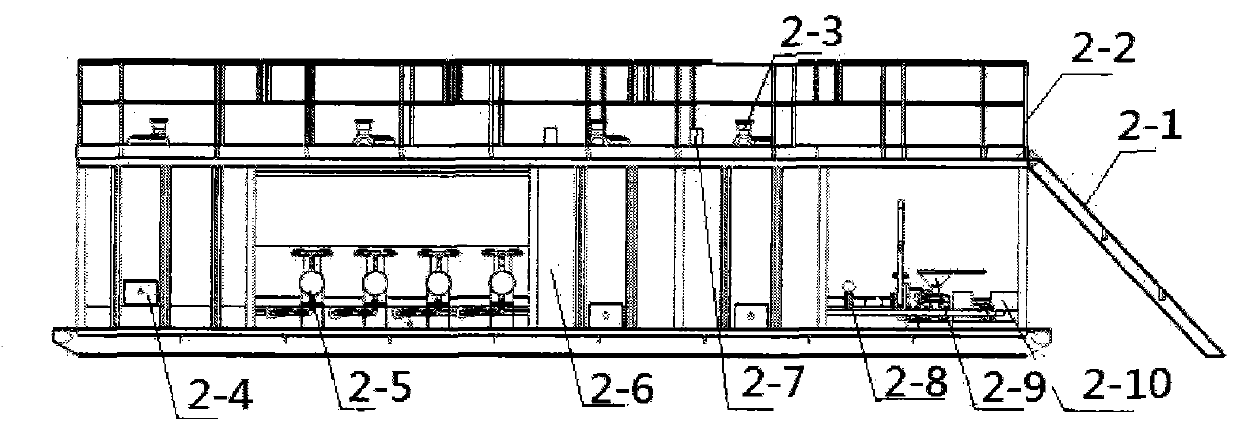

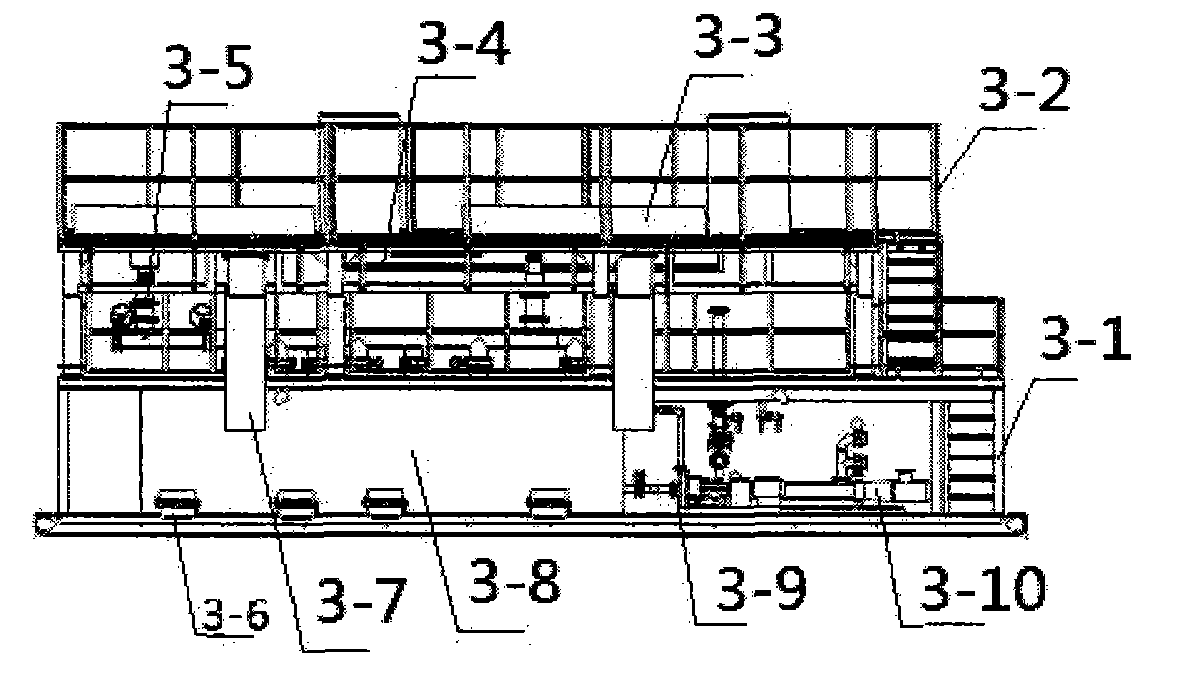

[0029] Such as figure 2 and image 3 As shown, a water-based drilling fluid waste solid-liquid separation equipment is built at the well site. The dispensing skid 1 is a two-layer steel frame structure. A ladder 2-1 is provided at the end of the dispensing skid for workers to enter the upper layer. The upper layer is also equipped with Guardrail 2-2, medicine tank 2-6 is installed on the lower floor, there are multiple medicine chambers in the medicine tank for containing different medicines, organic flocculants and inorganic flocculants are placed in different medicine chambers, and medicine tanks pass through The pipeline is connected with a dispensing funnel 2-9 and a centrifugal pump 2-10, and a plurality of agitators 2-4 and automatic feeders for dosing are installed on the medicine tank, all of which are used to complete the dispensing and adding of medicines. The other side is connected with diaphragm metering pump 2-5 by pipeline, and diaphragm metering pump has mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com