Insulation inspection tooling for polyimide film on the bracket of solar sail panel driving device of spacecraft

A polyimide film and insulation inspection technology, applied in the direction of testing the dielectric strength, etc., can solve the problems that the measurement angle and measurement force cannot be quantitatively controlled, the installation surface cannot be inspected, and the risk of operation is increased, so as to check the insulation film The work of the resistance value is simple and easy to operate, avoiding the effect that the floating resistance value does not meet the requirements, and reducing the risk of repeated disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

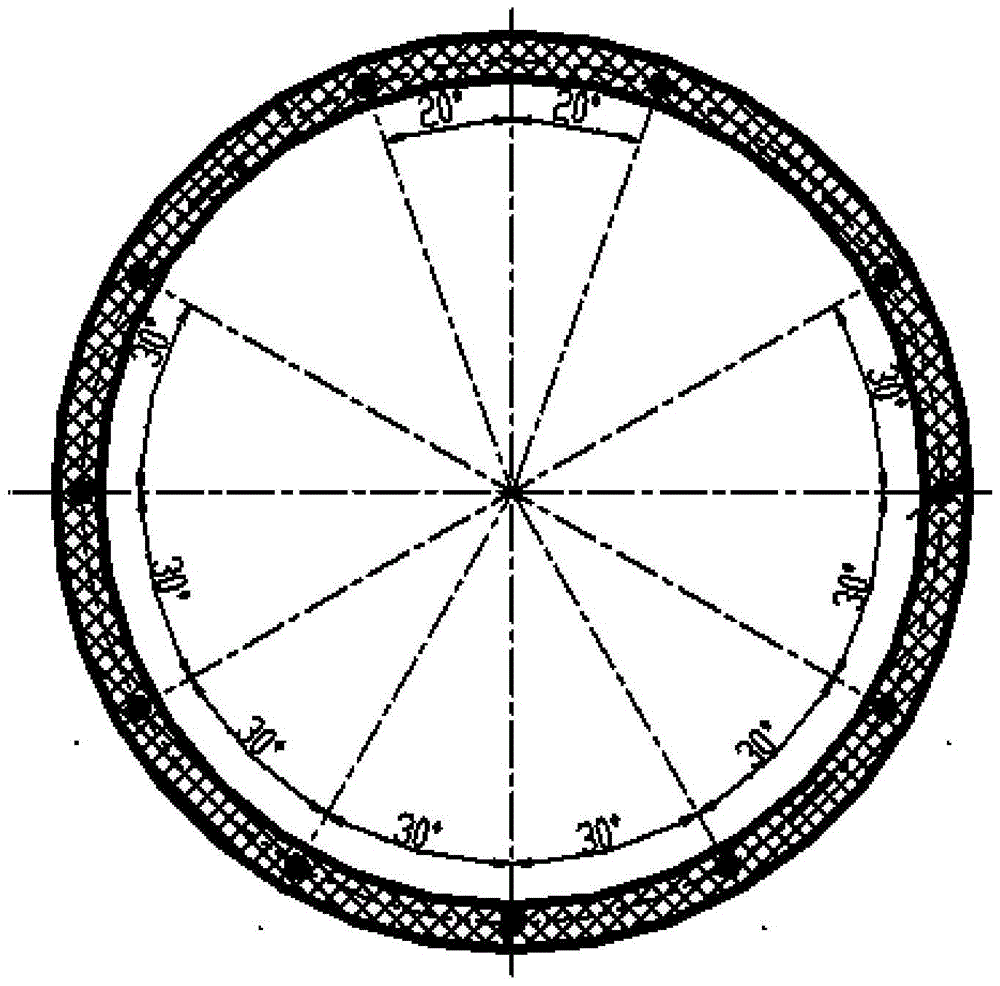

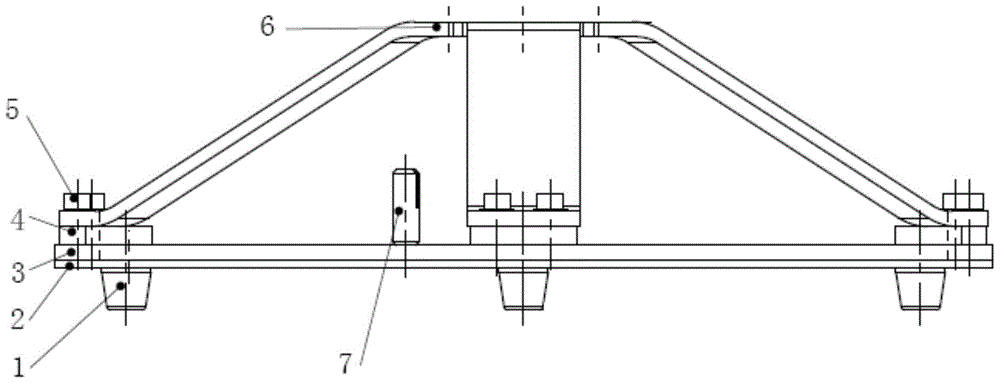

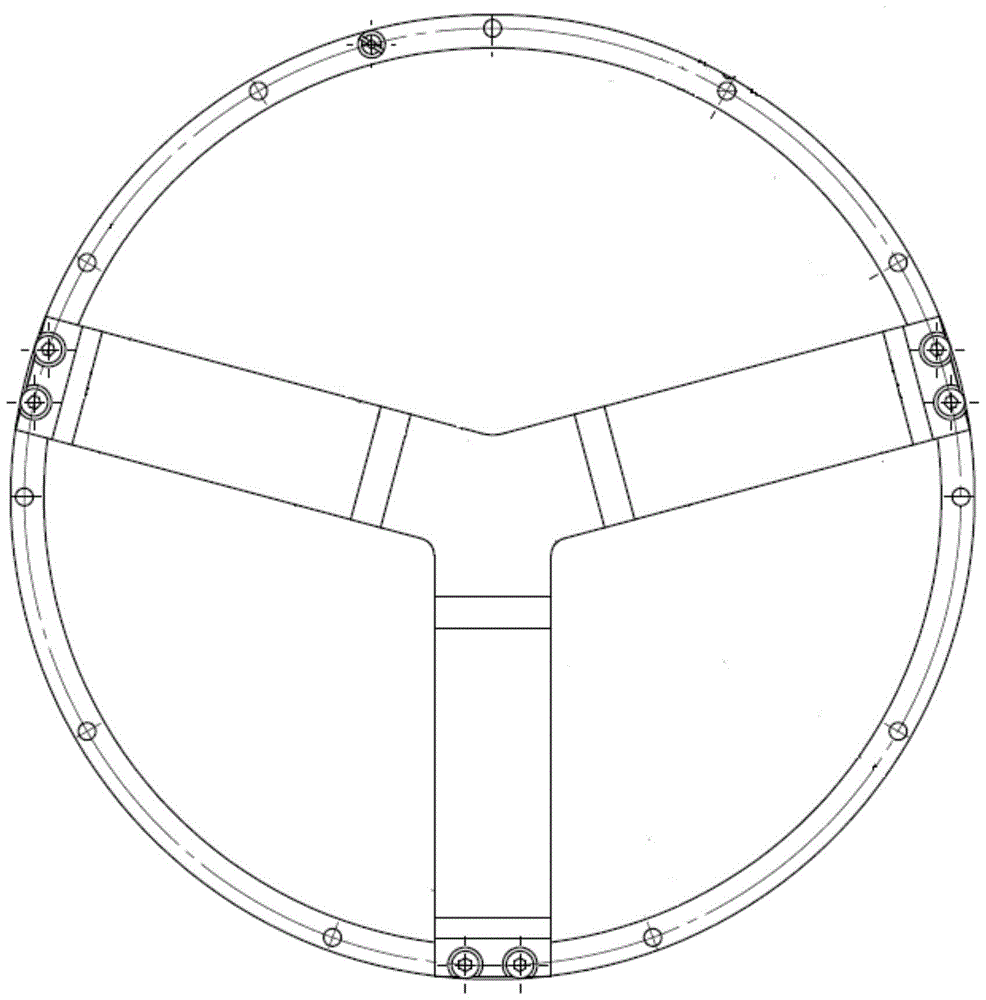

[0029] figure 2 It shows a schematic front view of the polyimide film insulation inspection tooling structure on the SADA bracket of the present invention; image 3 It shows a schematic top view of the polyimide film insulation inspection tooling structure on the SADA bracket of the present invention. The polyimide film insulation inspection tooling on the bracket of the spacecraft solar sail panel driving device of the present invention includes a measuring ring 3, an electric rubber ring, a handle 6, and a limit post for pressing on the polyimide film 1 and test lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com