Strong self-sucking double-suction pump

A self-priming pump and self-priming technology, which is applied in the direction of non-variable pumps, pumps, drive pumps, etc., can solve the problems of no advanced electronic automatic control, heavy mechanical auxiliary equipment, and no self-priming function of a single pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiment of accompanying drawing:

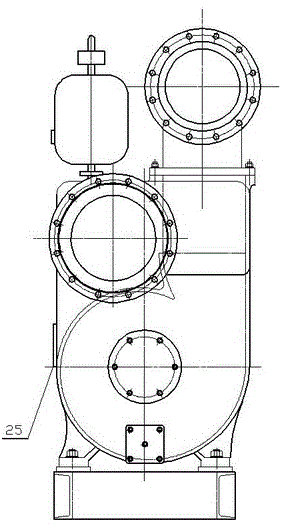

[0015] Such as figure 1 , 2 A strong self-priming double-priming self-priming pump is shown, which includes: motor 1, control cabinet 2, vacuum pump bracket 3, vacuum pump 4, pump cover 5, oil-water separator 6, connecting pipeline 7, water diversion tank 8, Solenoid valve 9, monitoring probe 10, inner cover 11, vacuum gauge 12, pump body 13, outlet check disc 14, outlet check valve 15, outlet connection flange 16, water filling and exhaust valve 17, inlet connection flange 18 , Impeller housing 19, impeller 20, skeleton oil seal 21, machine seal oil chamber cover 22, mechanical seal 23, base 24 and side contamination cover 25. The pump body 13 and the impeller casing 19 are integrally cast, and one end of the inner cover 11 is installed on the impeller casing 9, and the other end is installed on the pump body 13 and the pump cover 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com