Arm tip pulley mechanism, self-disassembly method of arm tip pulley mechanism and crane

A crane and self-disassembly technology, applied in the direction of cranes, etc., can solve the problems of increasing the weight and complexity of the structure, and cannot meet the fast self-disassembly and folding transportation of the arm tip pulley.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

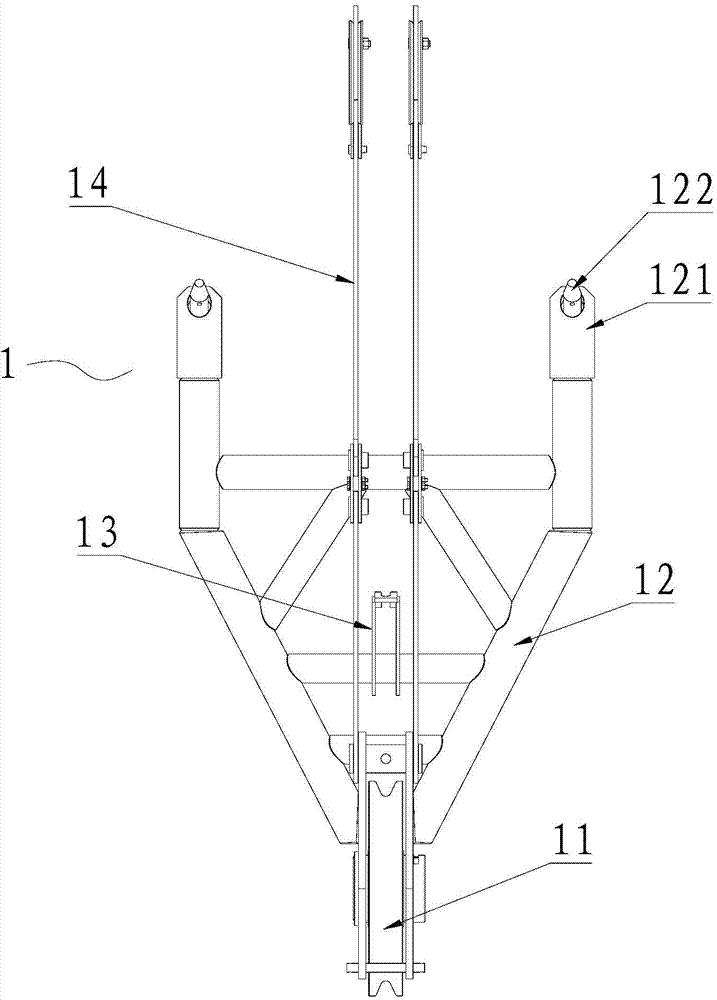

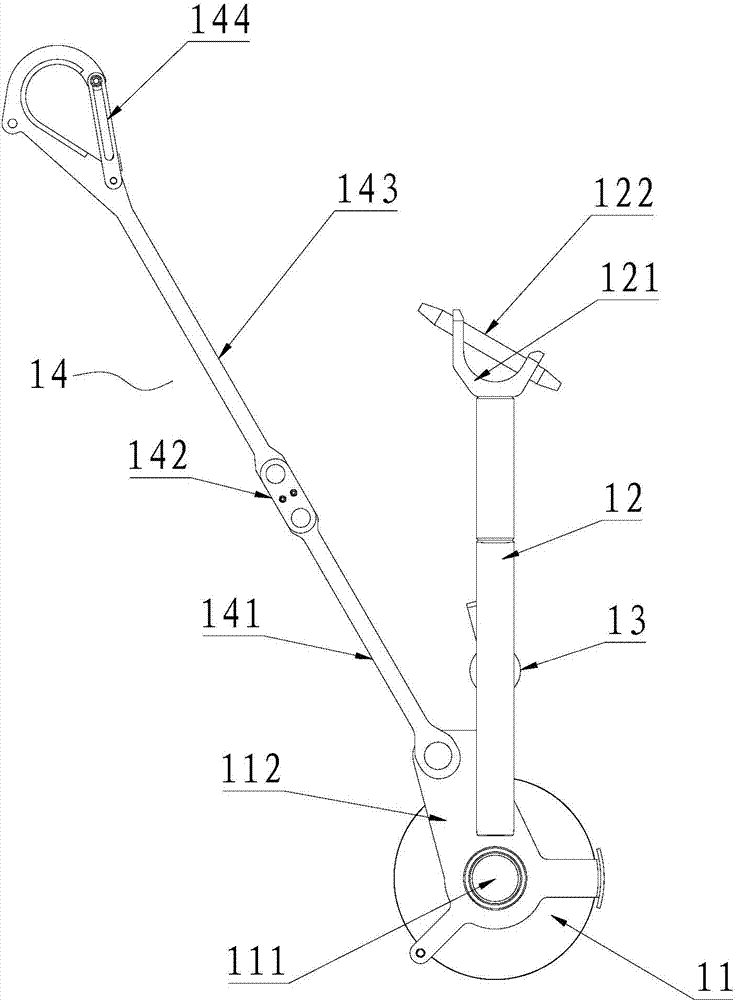

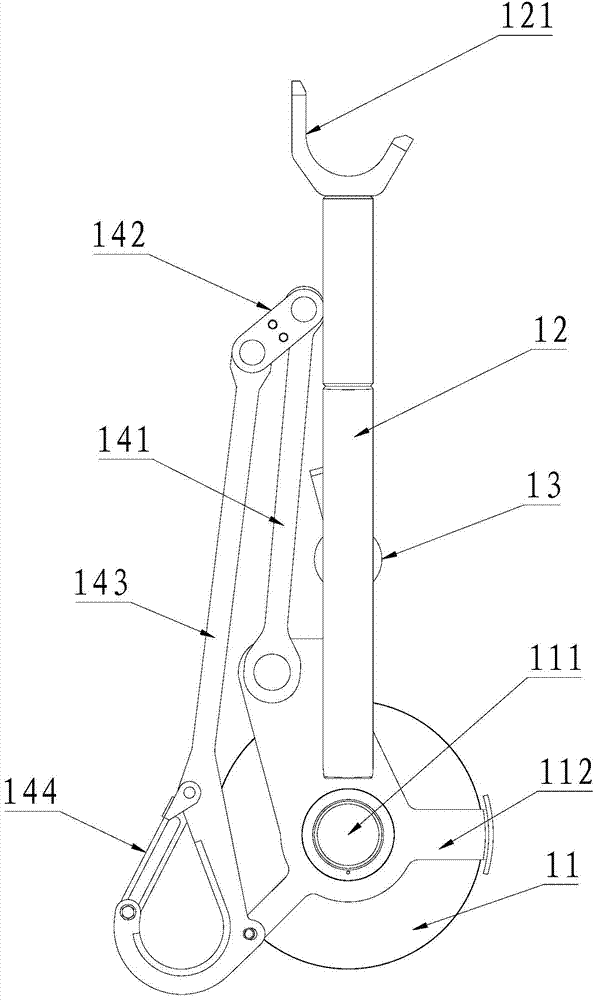

[0055] see Figure 1 to Figure 11 It can be seen from the relevant drawings that the arm tip pulley mechanism 1 described in this embodiment is a device used in conjunction with the arm head 3 of the main arm 2 of the crane. Usually, the arm head 3 of the main arm 2 is provided with a pulley 31 on the arm head, Arm head lower pulley 32, upper pulley shaft 34 and lower pulley shaft 33, the two ends of lower pulley shaft 33 are provided with the auxiliary arm installation hole 331 that is used to connect auxiliary arm.

[0056]The arm tip pulley mechanism 1 described in this embodiment includes a pulley frame 12 , an arm tip pulley 11 , lifting lugs 13 and a pull plate 14 . Specifically, the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com