All hydraulic caterpillar cranes

A crawler crane, full hydraulic technology, applied in cranes and other directions, can solve the problems of high disassembly and assembly costs of electric rail tower cranes, inability to meet hoisting requirements, and backward hydraulic drive systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

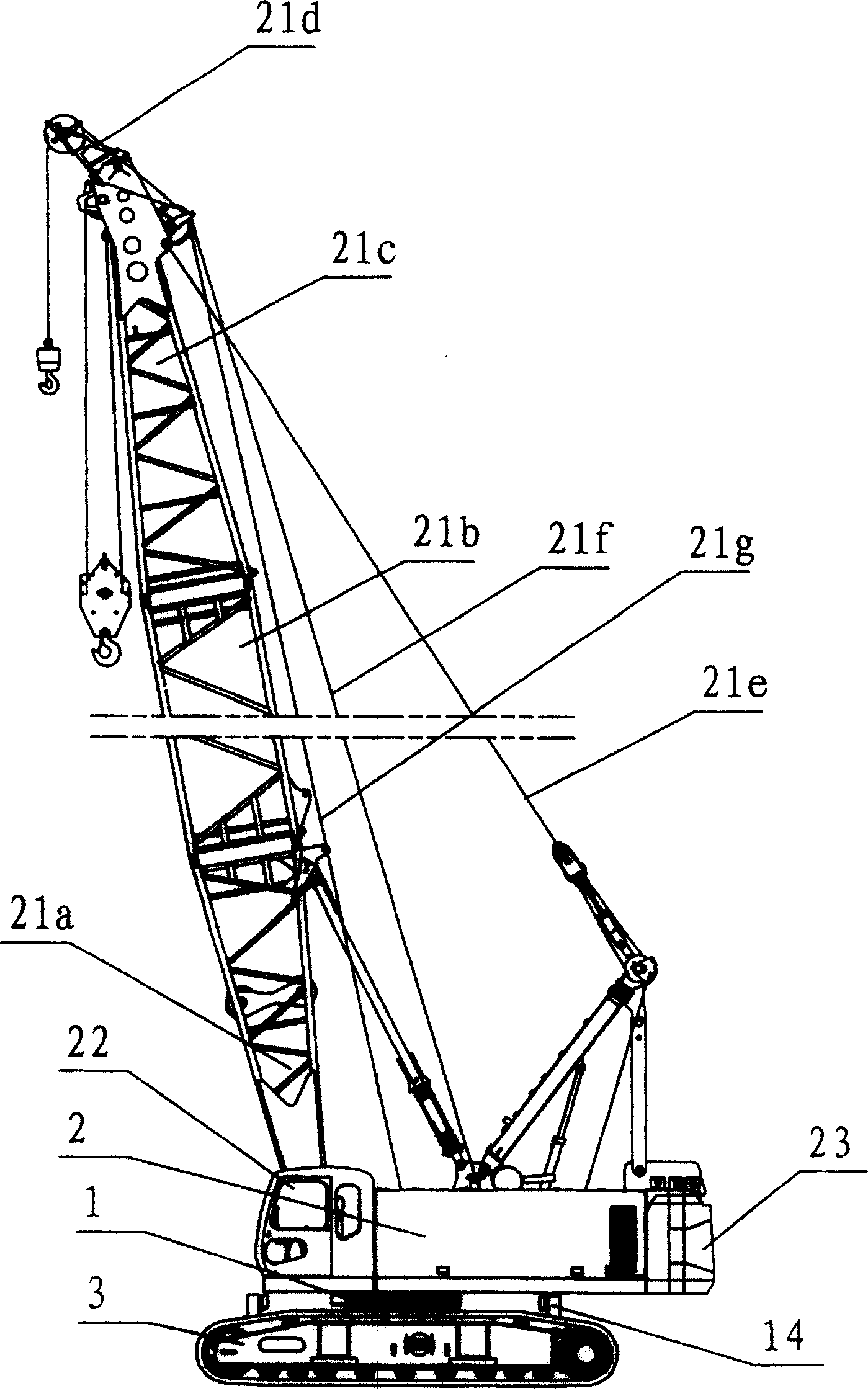

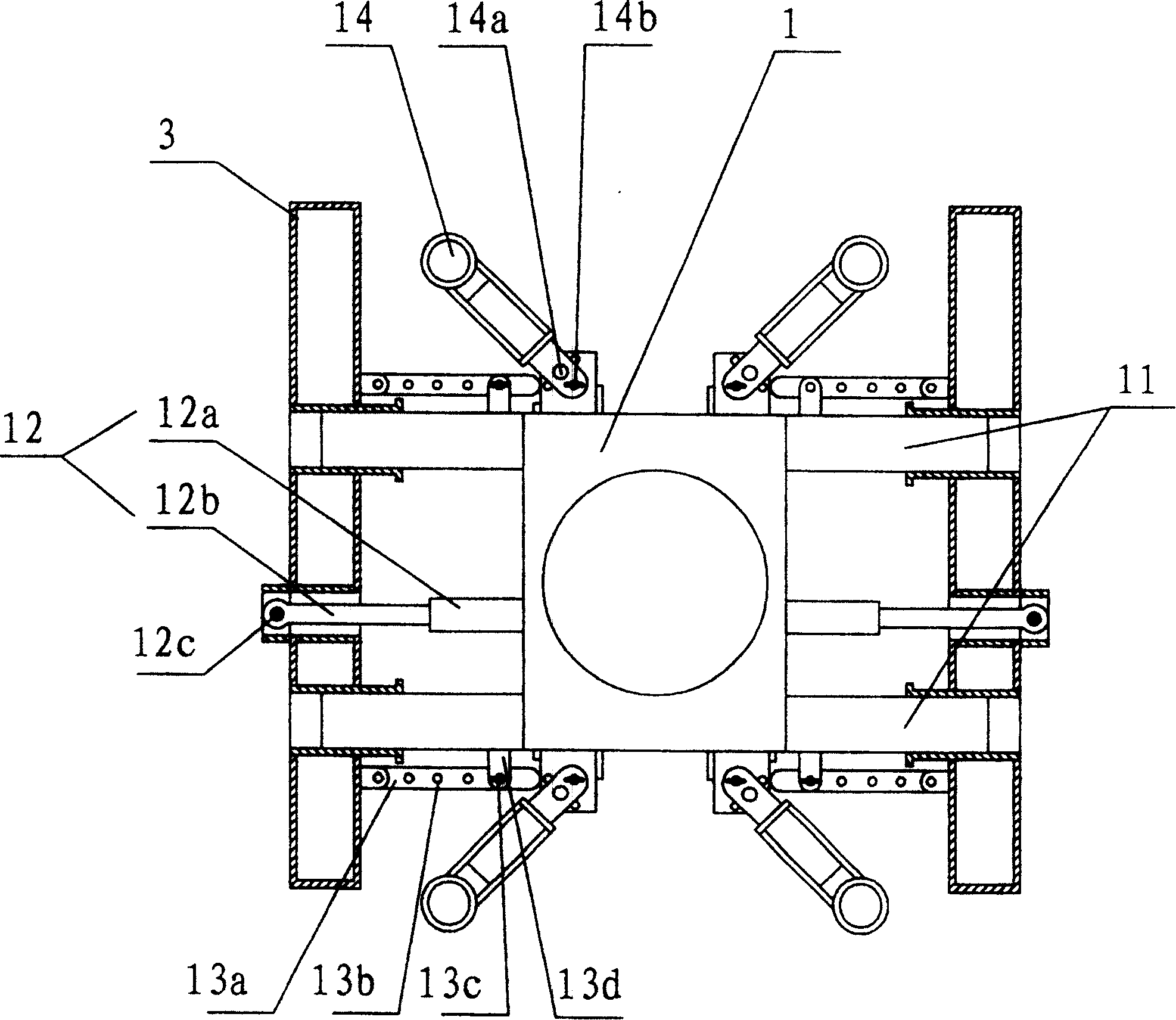

[0014] Embodiment one: if figure 1 , figure 2 As shown, the fully hydraulic crawler crane includes an intermediate body 1, crawler belt assemblies 3 are installed on both sides of the intermediate body 1, a revolving body 2 is installed on the intermediate body, and a boom assembly, an operating room 22, and a boom assembly are installed on the revolving body 2. power and hydraulic system and counterweight 23, the vehicle body 1 is equipped with hydraulic support legs 14 that can support the crane off the ground, the crawler belt assembly 3 can slide along the mounting arm 11 of the intermediate body 1, and the A push-pull device 12 that can push and pull the crawler belt assembly 3 along the mounting arm 11 is provided between the intermediate body 1 and the crawler belt assembly 3 , and a locking device 13 is also provided between the crawler belt assembly 3 and the intermediate body 1 .

[0015] The hydraulic support leg 14 is hinged on the vehicle body 1 through a pin sh...

Embodiment 2

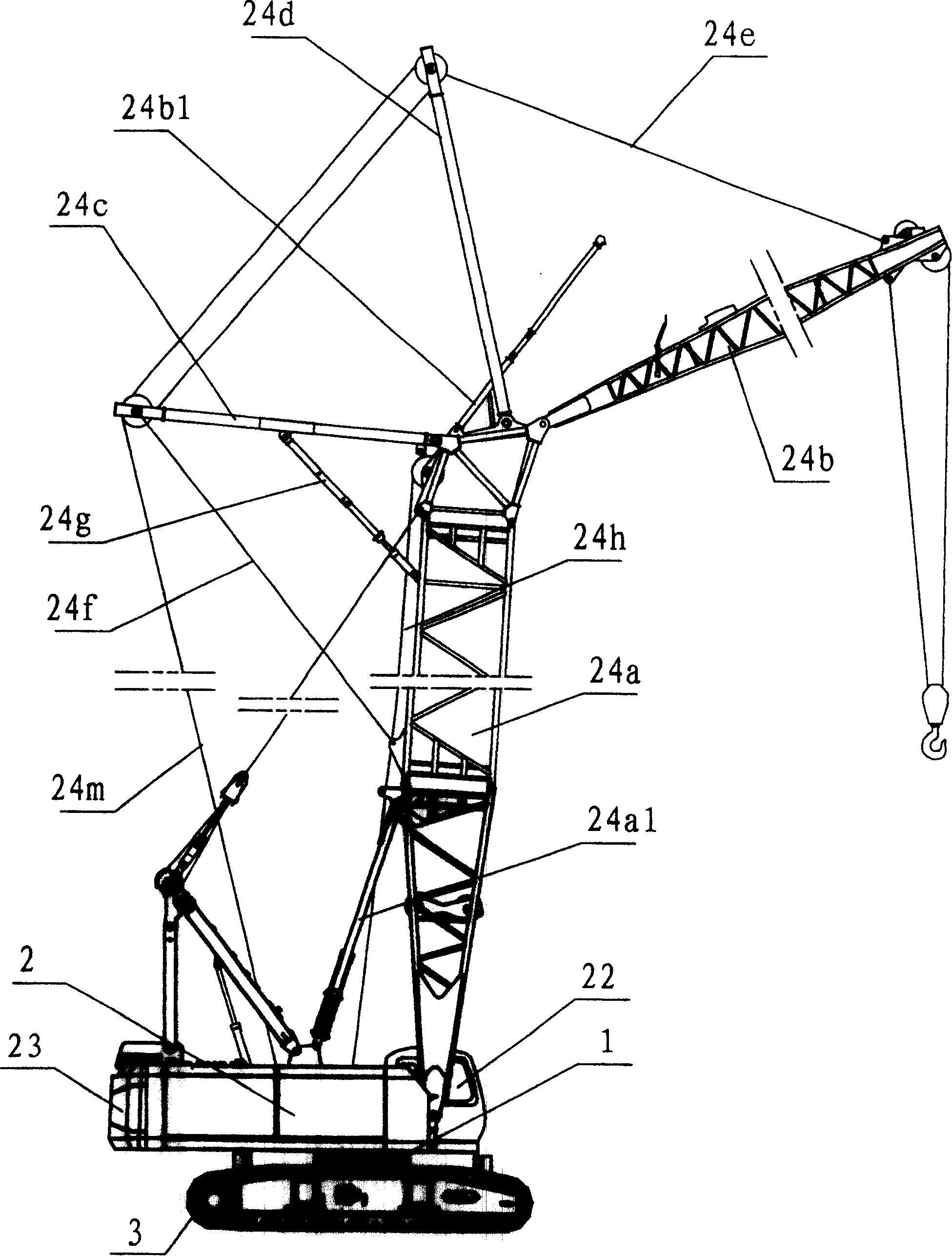

[0028] Embodiment two: if image 3 , Figure 4 , Figure 5 As shown, its structure is basically the same as that of Embodiment 1, and the difference lies in the structural form of the boom assembly, which is in the form of a tower lifting structure, including the main arm 24a, which is in a fixed state during work, The root of the main arm 24a is provided with a main arm anti-tilt device 24a1, an auxiliary arm 24b that is hinged with the main arm 24a and can realize amplitude change, a main support 24c, an auxiliary support 24d, an auxiliary Arm front cable 24e, secondary arm rear cable 24f, rear cable tensioning device 24g; main hook steel wire rope 24h for lifting and lowering heavy objects on the main hook by retracting and retracting; main luffing rope for realizing the amplitude of the auxiliary arm 24b by retracting and retracting .

[0029] The back cable tensioning device 24g includes a hydraulic cylinder 24g1 hinged to one of the main support 24c and the main arm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com