Catalyst dosing method for start-up of olefin conversion unit

A conversion device and catalyst technology, applied in the fields of organic chemistry, chemical recovery, ethylene production, etc., can solve the problems of small regenerator, difficulty in catalyst heat storage, and difficulty in establishing a bed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

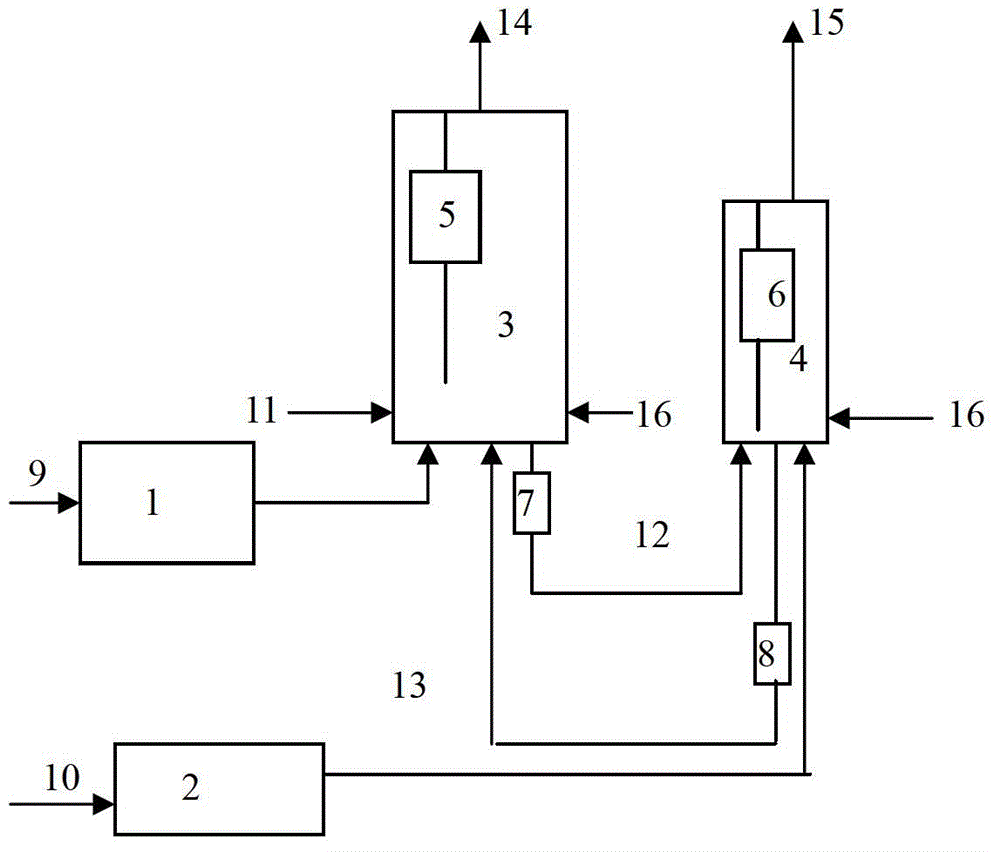

[0076] When starting up, the nitrogen gas 9 is overheated to 450°C by the start-up heating furnace 1 and then enters the reactor 3 to heat the reactor 3 to 540°C; at the same time, the hot air 10 with a temperature of 150°C coming from the regenerator 4 through the auxiliary combustion chamber 2 is heated up in advance to 540°C. The regenerator 4 is added first, and the dosing is added quickly at the beginning of the dosing to prevent the material leg from the regeneration cyclone separator 6 from being lost. The temperature of the catalyst added to the regenerator 4 is increased by adjusting the amount and temperature of the hot air 10 entering the regenerator 4. Requirements: During the heat storage stage of the regenerator 4, the reactor 3 starts to add dosing, and the dosing is rapid at the beginning stage, while ensuring that the temperature of the reactor does not drop sharply; After the legs, slow down the dosing speed and maintain the temperature of reactor 3. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com