Multi-shaft synchronous tightening equipment for wheel bolts

A multi-axis synchronization and bolt technology, which is applied to power tools, manufacturing tools, etc., can solve the problems of inability to control bolt stress interaction, low assembly accuracy, and troublesome operation, so as to achieve high-efficiency maintenance and assembly services and improve combat effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

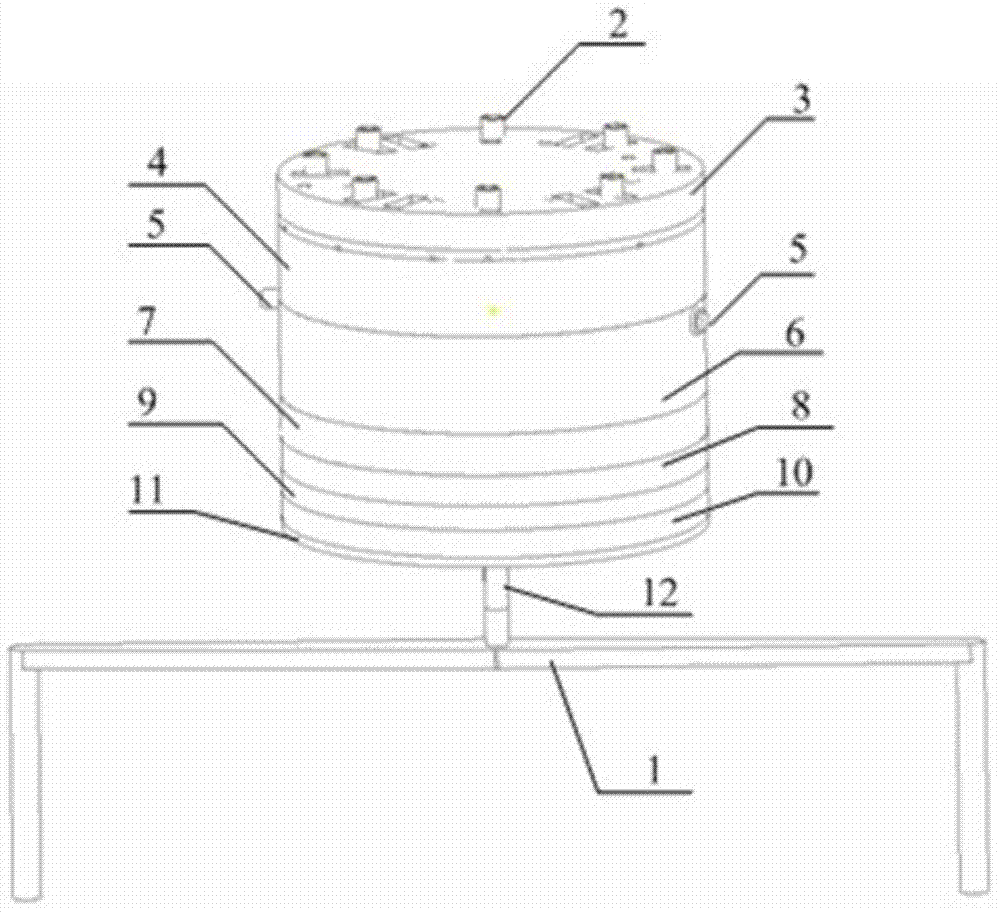

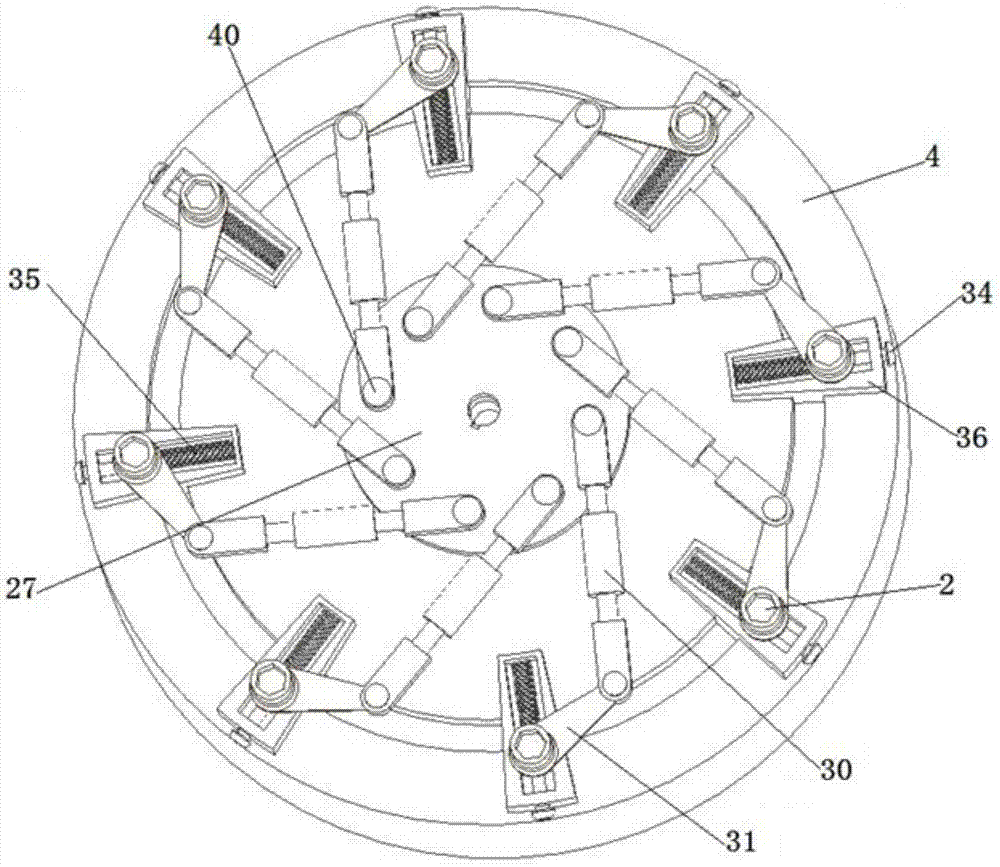

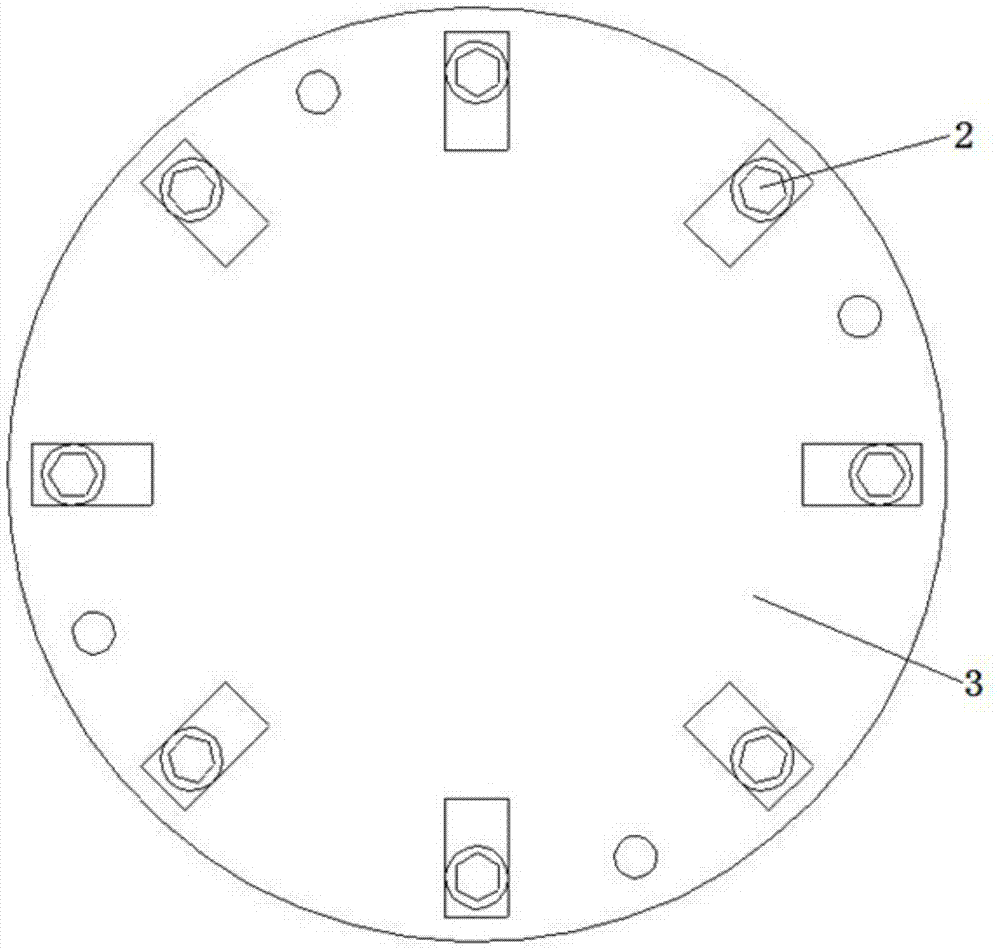

[0025] refer to figure 1 with figure 2 as well as image 3 , a multi-axis synchronous tightening device for wheel bolts, which consists of the following parts: a reduction mechanism (37) whose input end is connected to a motor or a shaking handle (1), and a reciprocating rotation mechanism (38) connected to an output end of the reduction mechanism (37) , a tightening mechanism (39) connected to the output end of the reciprocating mechanism (38). Among them, the tightening mechanism (39) includes the following main components: the chute disc (4), the circumferential adjustment slider (36) installed on the chute disc, and the surface of a plurality of hinge shafts (40) evenly distributed. The removable disc (27), the top cover (3) covered on the chute disc (4) and the removable disc (27), the tightening link (30) with one end sleeved on the hinge shaft (40), The tightening crank (31) hinged with the tightening connecting rod (30), the ratchet mechanism (32) arranged on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com