Solar-assisted volatile fermentation products production processes

A fermentation product and production process technology, applied in the field of solar-assisted volatile fermentation product production process, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] Materials and methods

[0068] Fermentation medium (simulation): for embodiment 1~4, its fermentation medium is as follows: in ethanol solution experiment, the denatured ethanol ( Aalborg, Denmark) was diluted to 20L so that the final concentration of ethanol was approximately 12% v / v. In the n-butanol or sec-butanol solution experiment, dilute 400ml of n-butanol or sec-butanol (BDH Prolabo, GPR Rectapur, VWR Bie & Berntsen, Denmark) fermentation medium to 20L with tap water, so that n-butanol Or the final concentration of sec-butanol is about 2% v / v. For embodiment 5, its fermentation medium is as follows: use the denatured ethanol of 4L93%v / v ( Aalborg, Denmark) was diluted to 20L so that the final concentration of ethanol was approximately 19% v / v.

Embodiment 5

[0068] Fermentation medium (simulation): for embodiment 1~4, its fermentation medium is as follows: in ethanol solution experiment, the denatured ethanol ( Aalborg, Denmark) was diluted to 20L so that the final concentration of ethanol was approximately 12% v / v. In the n-butanol or sec-butanol solution experiment, dilute 400ml of n-butanol or sec-butanol (BDH Prolabo, GPR Rectapur, VWR Bie & Berntsen, Denmark) fermentation medium to 20L with tap water, so that n-butanol Or the final concentration of sec-butanol is about 2% v / v. For embodiment 5, its fermentation medium is as follows: use the denatured ethanol of 4L93%v / v ( Aalborg, Denmark) was diluted to 20L so that the final concentration of ethanol was approximately 19% v / v.

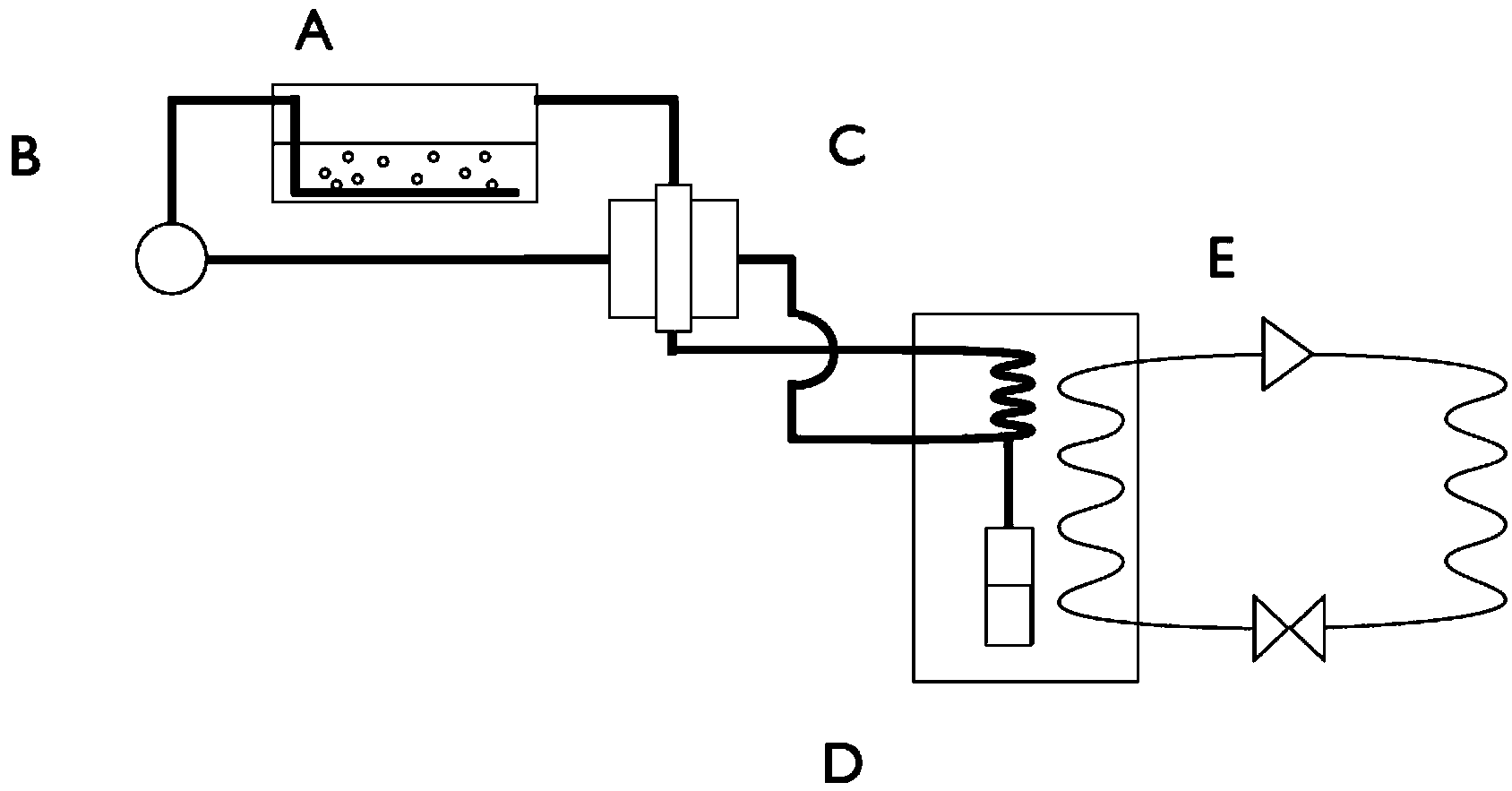

[0069] In all experiments, the depth of the fermentation medium in the fermentation chamber was approximately 20 cm. The dimensions of the fermentation chamber were 40 cm in height, 40 cm in length and 32 cm in width. The four sides and the bott...

Embodiment 1

[0079] Example 1: Day / night ethanol simulation without PHE+E

[0080] A 12% v / v ethanol solution was used to simulate the ethanol fermentation medium in the above-mentioned fermentation chamber. White spotlights were on for 10 hours and off for 14 hours to simulate the natural day / night cycle. During the 10-hour period with light, CO 2 The outer surface of the fermentation medium exposed per square meter is about 15m 3 The / hour rate cycles through the headspace and condensing unit. The area of the exposed outer surface of the fermentation medium is 0.128m 2 . Within two days, regularly record the temperature of the fermentation medium, the head space, the cooling water of the tubular condensing unit, and the air discharged from the tubular condensing unit, and the data results are as follows: figure 2 shown. Each time the ethanol condensate was measured, it was returned to the fermentation chamber again. Therefore, the fermentation medium contained a relatively cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com