Sample injection needle with automatic detection function

An automatic detection and injection needle technology, applied in the field of medical equipment, can solve the problems of inaccurate sample volume and low sample injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

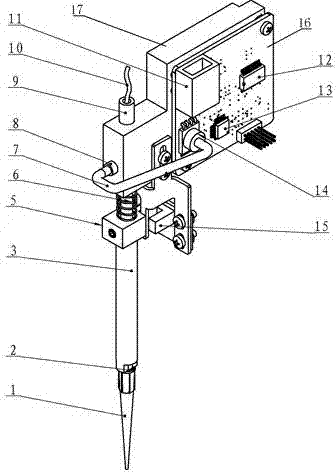

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, a sampling needle with automatic detection function includes a sample suction device for sucking samples, a pressure measuring device for detecting pressure changes inside the sampling needle, and a fall-off detection device for detecting whether the TIP head 1 is installed and falling off. The control circuit board 16 for pressure measurement and TIP head 1 shedding measurement.

[0024] The sampling device includes: a sampling needle 2, a hose 10 connected to the upper end of the sampling needle 2, the lower end of the sampling needle 2 is inserted into the TIP head 1, and the hose 10 is externally covered with a hose joint sleeve 9 and an external The micropump is connected to draw the sample.

[0025] The pressure measuring device includes: a connecting hose 7 and an air pressure sensor 14 for detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com