A range hood control system with constant air volume output and its control method

A control method and range hood technology, applied in the direction of oil fume removal, heating method, household heating, etc., can solve problems such as failure, grease contamination, etc., and achieve the effect of small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

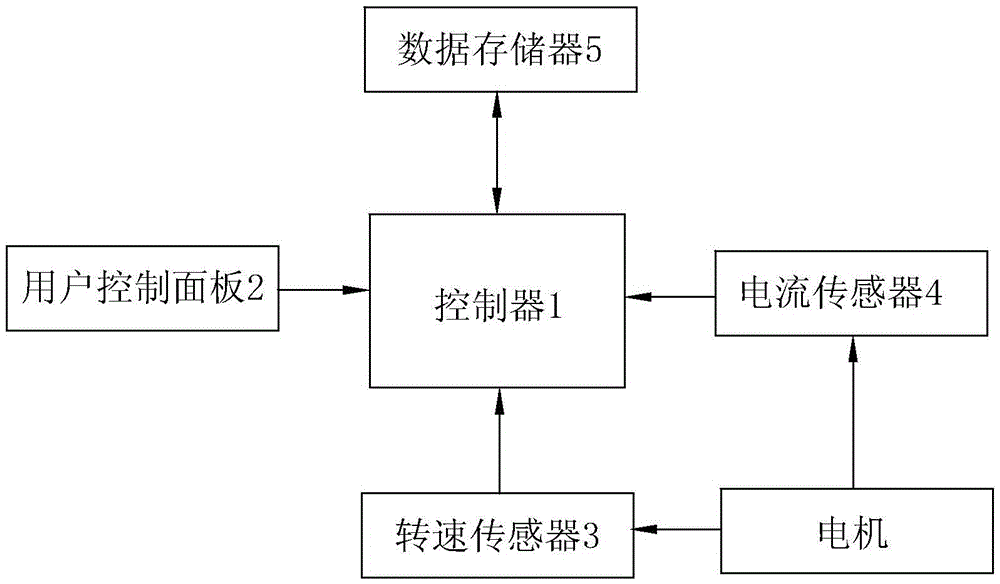

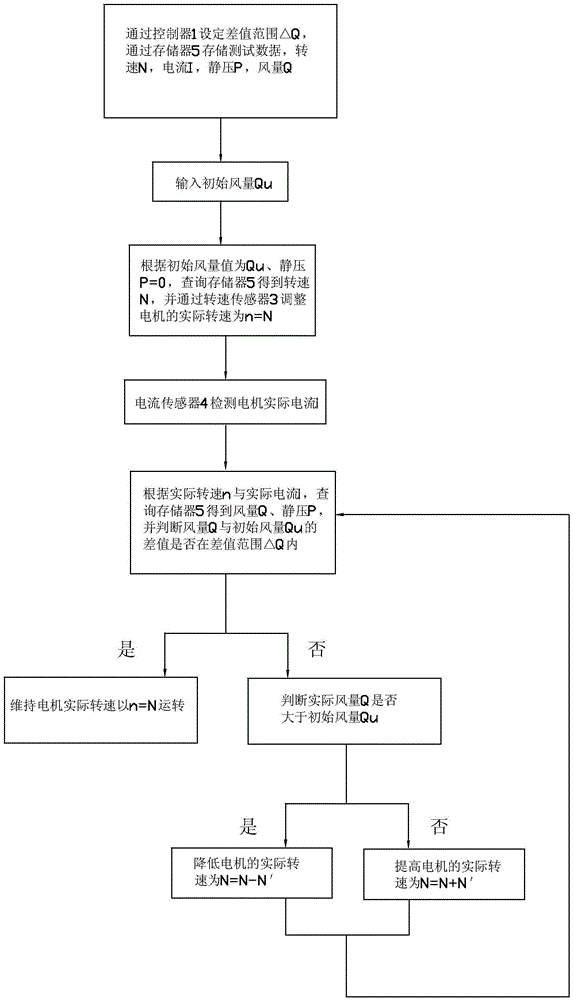

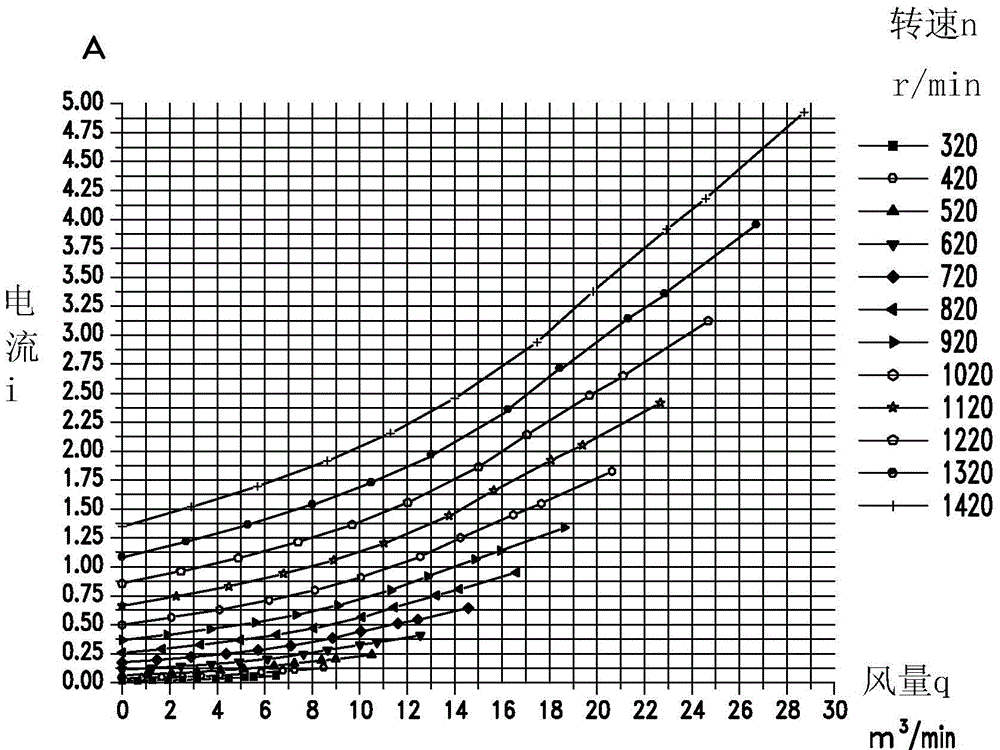

[0028] Such as figure 1 As shown, a range hood control system outputting a constant air volume includes a controller 1 connected to a user control panel 2 for the user to input the initial air volume Qu, and a speed sensor 3 for detecting the actual speed n of the motor , a current sensor 4 for detecting the actual current i of the motor, a memory 5 for storing data such as speed N, current I, static pressure P, and air volume Q, wherein the air volume is proportional to the rotational speed, and the static pressure is proportional to the square of the rotational speed , the current is proportional to the cube of the rotational speed, the difference range △Q is set by the controller 1, according to the initial air volume Qu, when the static pressure is 0, the rotational speed N is obtained by querying the memory 5, and the actual ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com