Internal leakage detection method of steam trap based on detection of pipe wall temperature in front of the valve

A technology of pipe wall temperature and steam traps, which is applied in measuring devices, testing of fluid tightness, testing of machine/structural components, etc., and can solve problems such as valve leakage, hidden dangers of equipment operation safety, and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

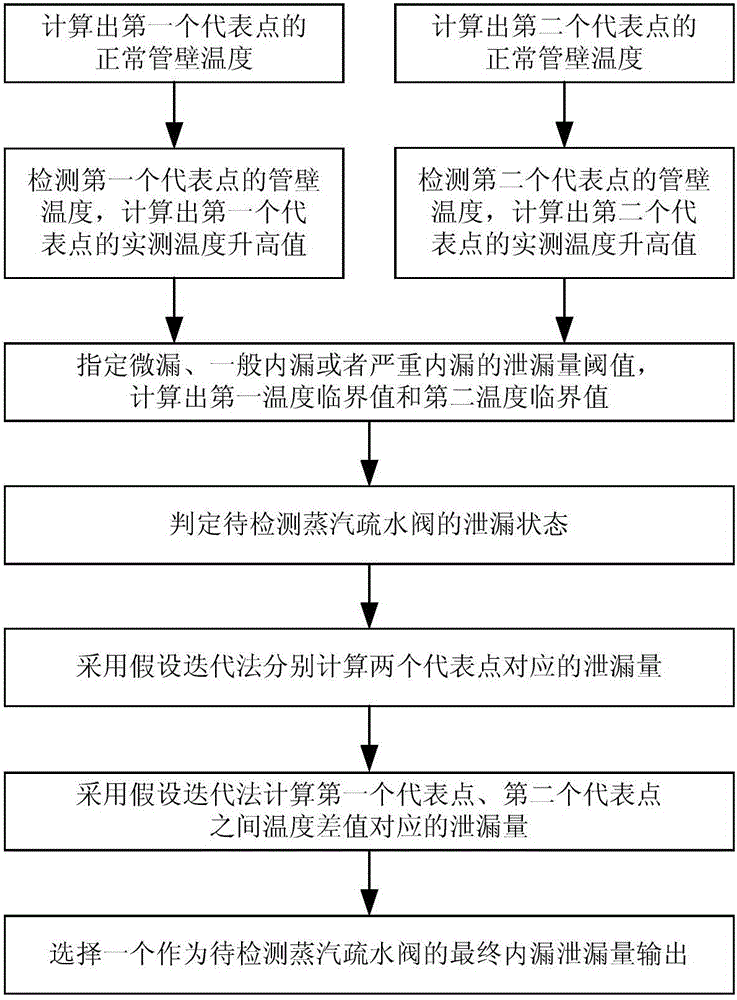

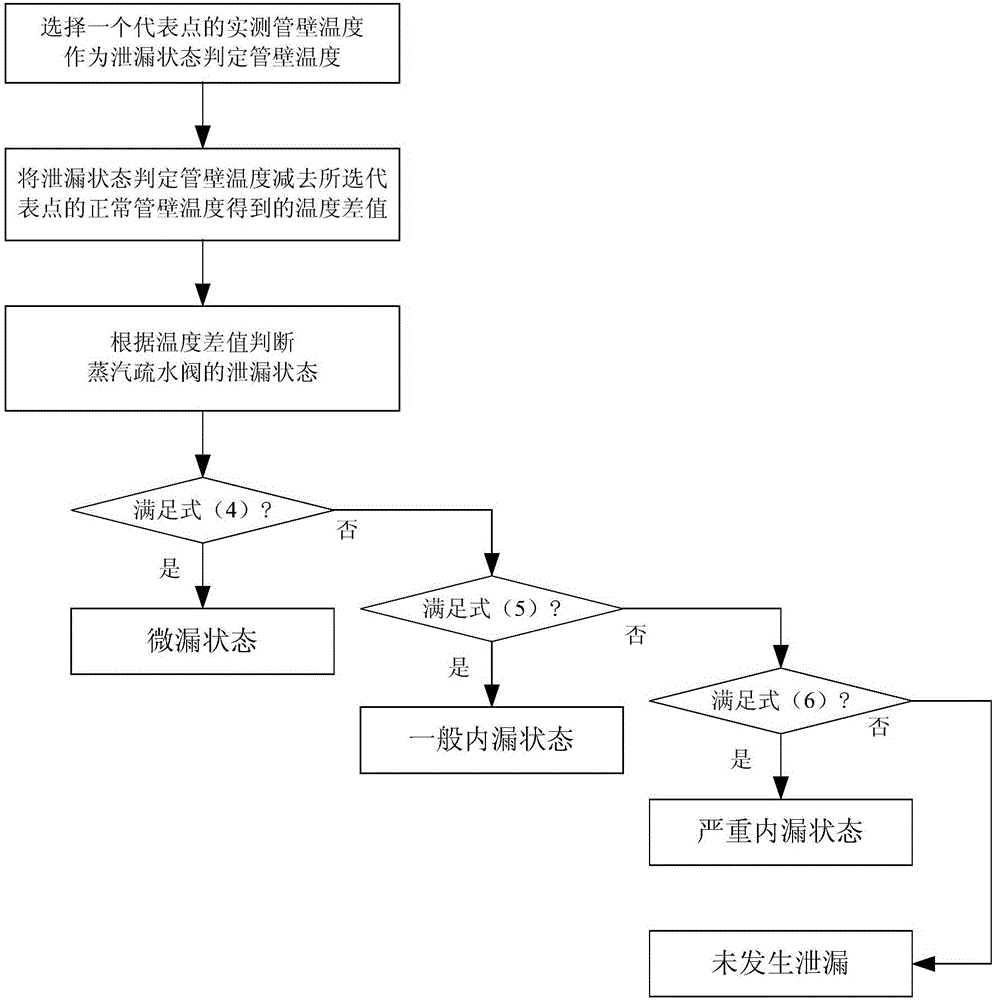

[0085] Such as figure 1 As shown, the steps of the steam trap internal leakage detection method based on the pipe wall temperature detection in front of the valve in this embodiment are as follows:

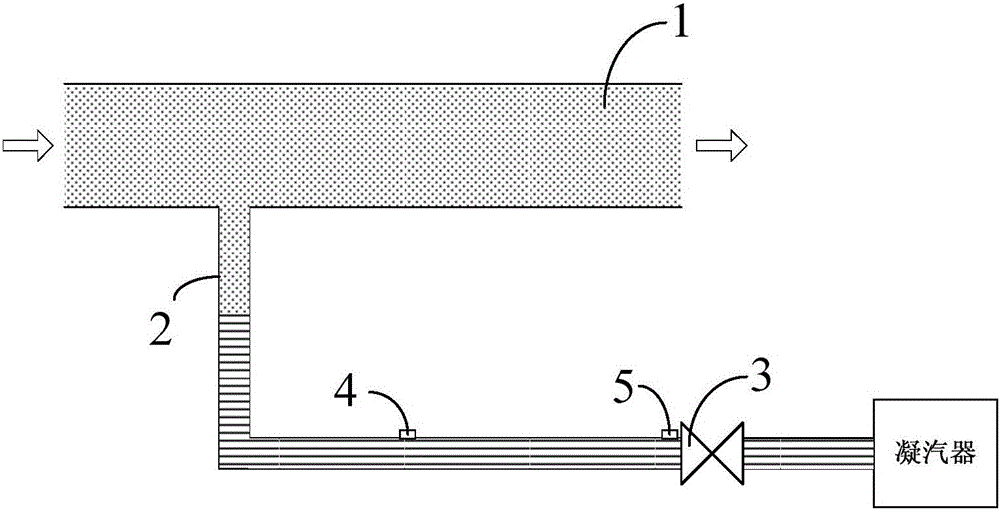

[0086] 1) Calculate the normal pipe wall temperature of the first representative point and the normal pipe wall temperature of the second representative point respectively according to formula (1). To detect the position of the steam trap, the second representative point is located on the drain pipe at the front end of the steam trap to be tested, and the second representative point is located on the drain pipe at the front end of the first representative point and is at a distance from the first representative point specified distance;

[0087] t gb1 =β' 0 +β' 11 (P / P cr )+β' 12 (P / P cr ) 2 +β' 21 (T / T cr )+β' 22 (T / T cr ) 2

[0088] +β' 31 (L / L max )+β' 32 (L / L max ) 2 +β' 41 (D / D max )+β' 42 (D / D max ) 2 (1)

[0089] +β' 51 (h gb / h gb-max )+β' 52 (h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com