Generator rotor strength calculation method capable of achieving parametric modeling

A generator rotor, parametric modeling technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of inability to calculate the concentrated stress at the fillet, prone to operation errors, deviation of calculation results, etc. Achieve the effect of shortening the calculation cycle, reducing the design cost, and avoiding the deviation of the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the present invention more obvious and understandable, the present invention will be further described with preferred embodiments.

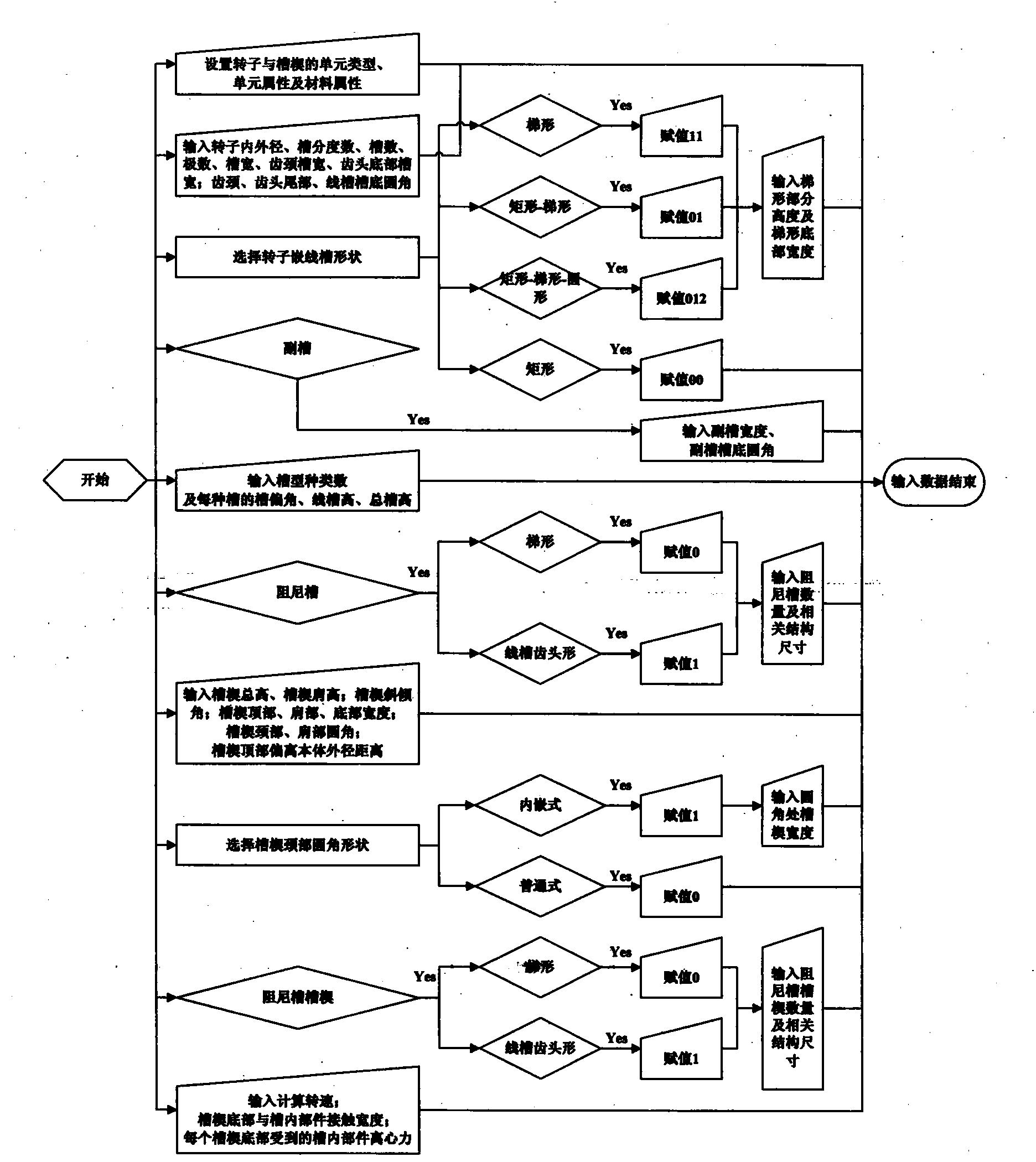

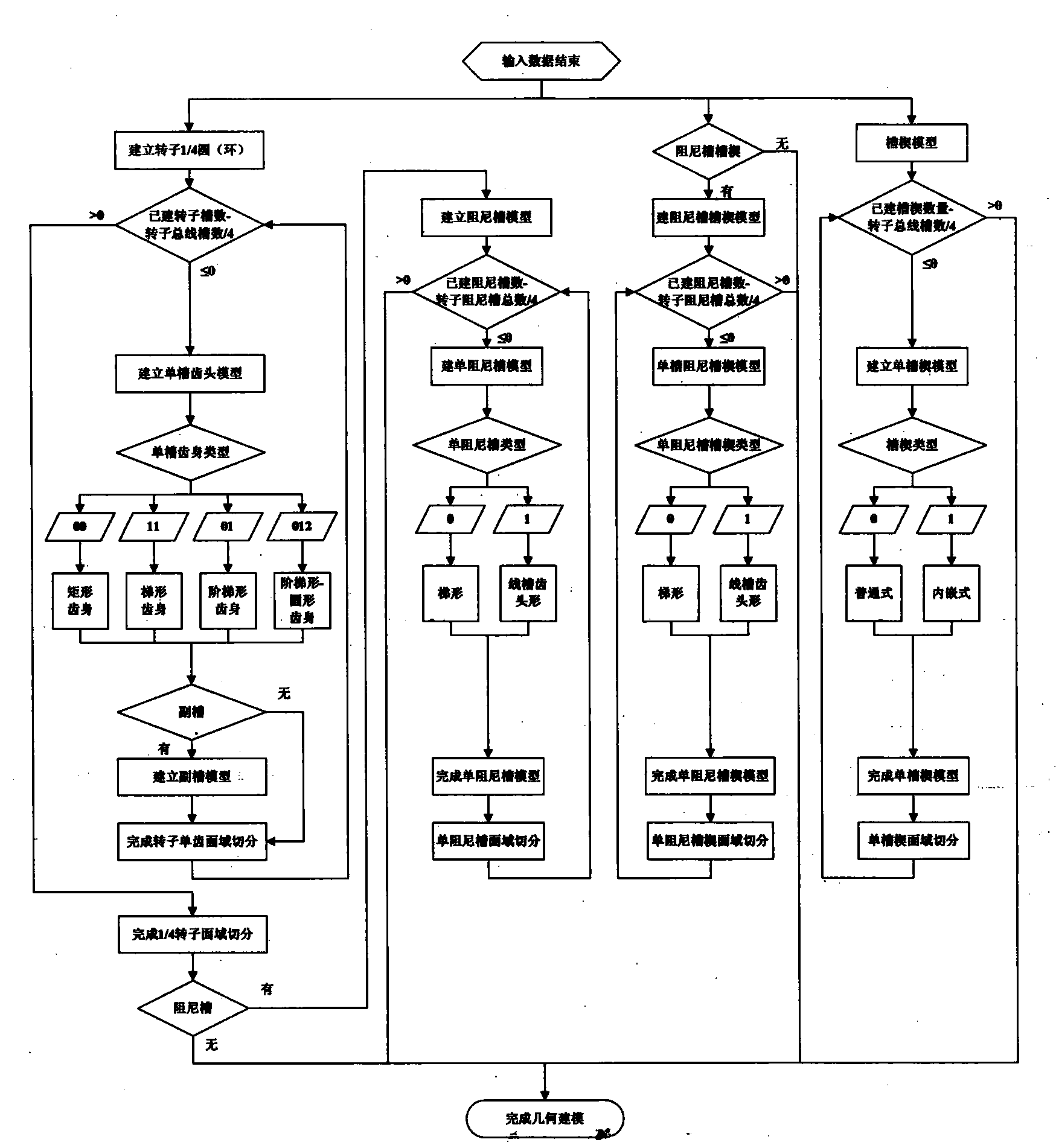

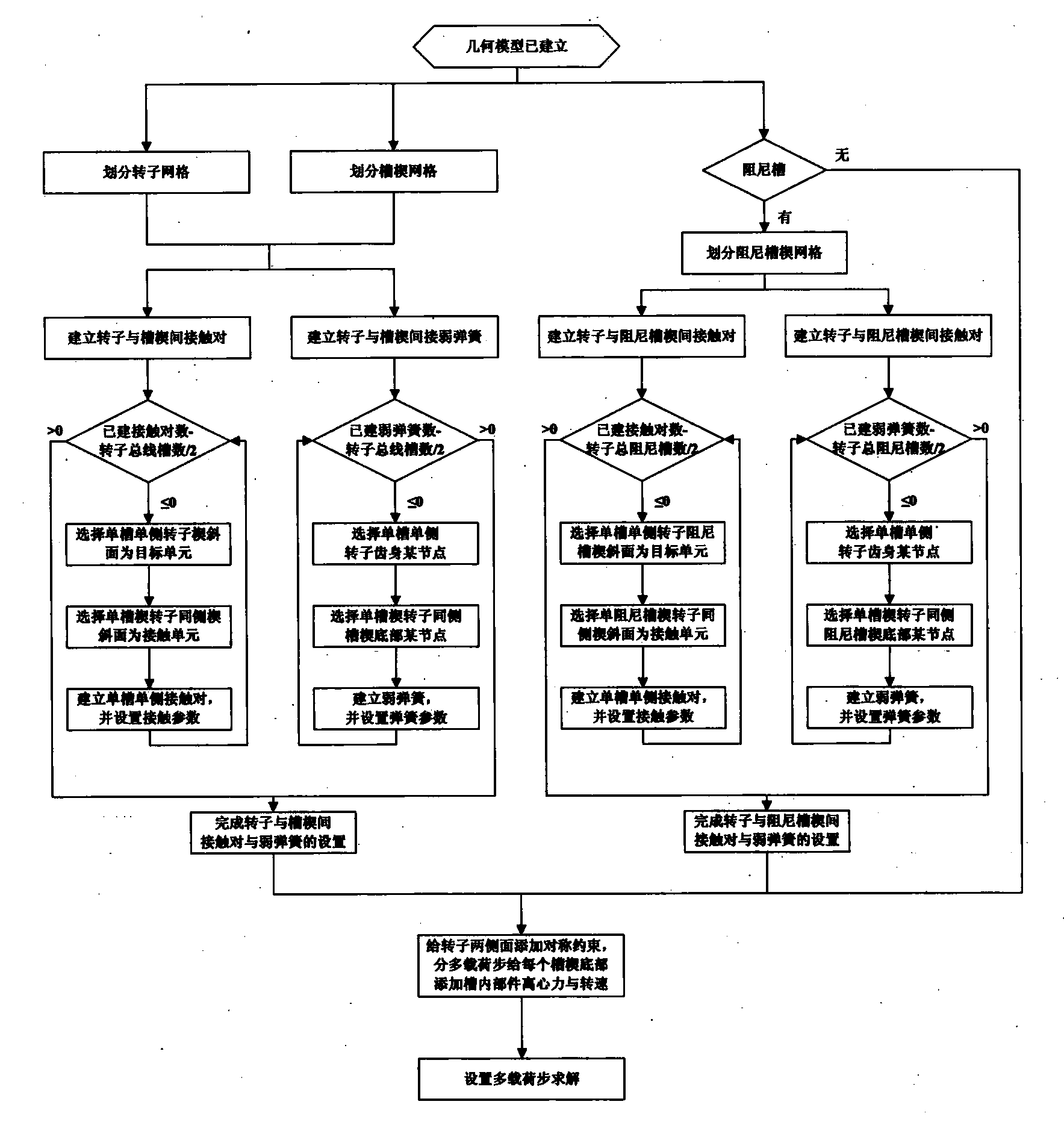

[0053] The invention provides a parameterizable modeling method for calculating the strength of a generator rotor, the steps of which are as follows:

[0054] Step 1. Use the classic formula to calculate the pressure exerted on the bottom surface of the slot wedge by the parts inside the slot under the action of centrifugal force. The formula is generally: F=mrω 2 , where m is the mass of the parts in the tank, r is the radius of the center of mass of the parts in the tank, and ω is the calculated rotational speed.

[0055] Step 2. Open this parameterized rotor strength calculation program in the text editor, set the element and material properties of the rotor and slot wedge, contact element, weak spring element and other element types and properties; input the structure type and structure of the rotor and slot wedge Dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com