Intelligent lifting carrier of stereo garage

A technology of three-dimensional garages and carriers, which is applied to buildings, building types, and buildings where cars are parked. It can solve the problems of difficult processing, increased cost, and high installation requirements, so as to reduce processing difficulty and installation accuracy, and save processing costs. , The effect of simplifying the running track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Describe the present invention in detail below in conjunction with accompanying drawing:

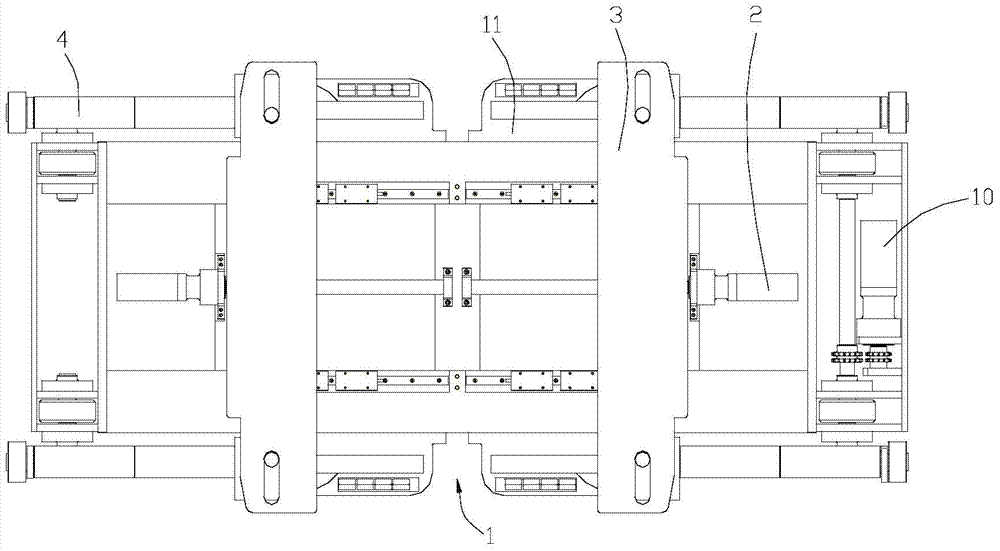

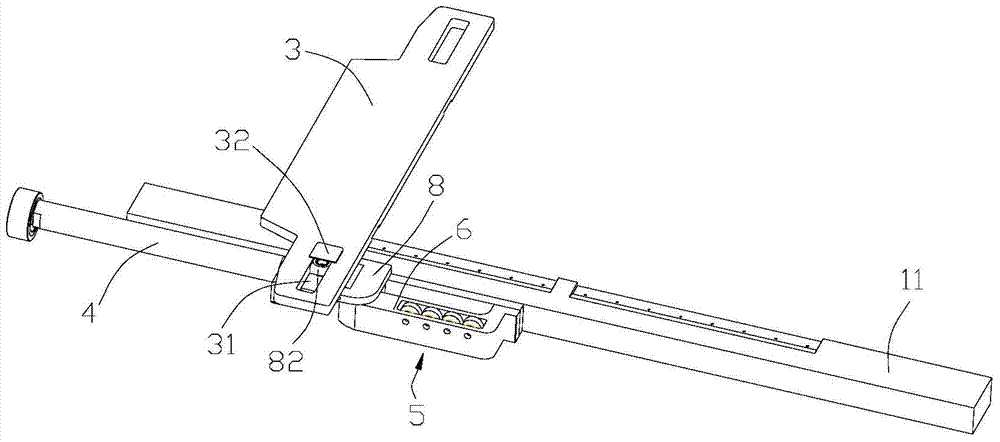

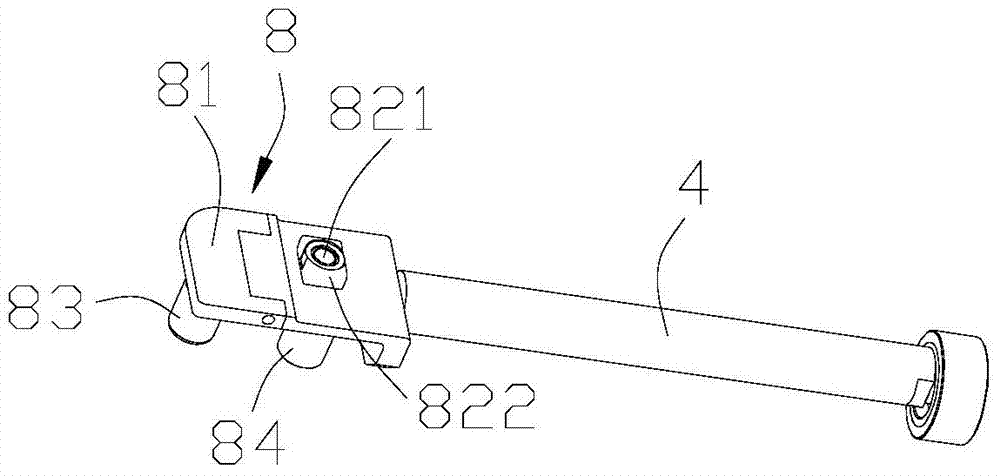

[0023] Such as figure 1 The three-dimensional garage intelligent lifting carrier of the present invention includes a transport frame 1 containing two longitudinal beams 11 and at least one transition plate 3 driven by a power unit 2 to move longitudinally along the two longitudinal beams. Generally, two transition plates are used to drive four arms. Holding rods, every two holding rods hold a tire; the driving device adopts a threaded rod and nut transmission mechanism arranged longitudinally in the middle of the transition plate, and the transition plate is driven to move through the transmission of the threaded rod and nut; each transition plate 3 ends A guide seat 8 is respectively installed on the lower side, and a holding rod 4 for holding the vehicle tire is fixedly installed at the outer end of each guide seat on the side away from the longitudinal beam. The transition plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com