Benzene-free stable laser anodized aluminum color layer coating composition and preparation method thereof

A stable, composition technology, applied in coatings and other directions, can solve problems such as the inability to meet the stability of benzene-containing coatings, and achieve the effects of eliminating the risk of heavy metals exceeding the standard, excellent stability, and wide adaptability to temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

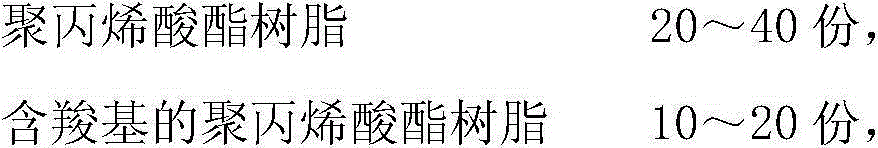

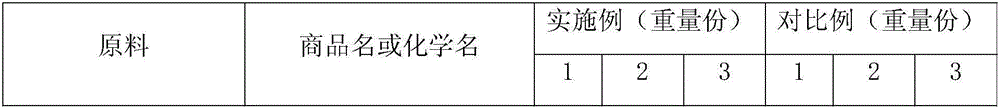

[0026] This embodiment relates to a benzene-free stable laser anodized aluminum color layer coating composition, including the components and dosage shown in Table 1.

[0027] The preparation method of the benzene-free stable type laser anodized aluminum color layer coating composition of the present embodiment comprises the following process steps:

[0028] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0029] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0030] (3) Put the resin component into the reaction kettle, control the stirring rate to be 500rpm, and stir for 4h to fully dissolve the resin component;

[0031] (4) When the resin component is completely dissolved, put the additives into the reaction kettle, control the stirring rate to 500rpm, and stir for 15 minutes until the additives are fully dispersed and evenly distributed;

[0032] (5) Put the re...

Embodiment 2

[0034] This embodiment relates to a benzene-free stable laser anodized aluminum color layer coating composition, including the components and dosage shown in Table 1.

[0035] The preparation method of the benzene-free stable type laser anodized aluminum color layer coating composition of the present embodiment comprises the following process steps:

[0036] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0037] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0038] (3) Put the resin component into the reactor, control the stirring rate to be 600rpm, and stir for 2h to fully dissolve the resin component;

[0039] (4) When the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring rate to 400rpm, and stir for 20min until the additives are fully dispersed and evenly distributed;

[0040] (5) Put the required pigm...

Embodiment 3

[0042] This embodiment relates to a benzene-free stable laser anodized aluminum color layer coating composition, including the components and dosage shown in Table 1.

[0043] The preparation method of the benzene-free stable type laser anodized aluminum color layer coating composition of the present embodiment comprises the following process steps:

[0044] (1) Prepare raw materials according to the components and parts by weight shown in Table 1:

[0045] (2) Put the solvent in the reaction kettle according to the formula, turn on the stirring device, and mix evenly;

[0046] (3) Put the resin component into the reaction kettle, control the stirring rate to be 550rpm, and stir for 3h to fully dissolve the resin component;

[0047] (4) When the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring rate to 450rpm, and stir for 30 minutes until the additives are fully dispersed and evenly distributed;

[0048] (5) Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com