Urea finished product packaging conveyor line that can prevent missing codes

A technology of conveying line and spraying leakage, which is applied in the field of finished packaging bag conveying line, can solve the problems of code spraying leakage and spraying, achieve the effect of solving the phenomenon of code leakage and improving the quality of printing code

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

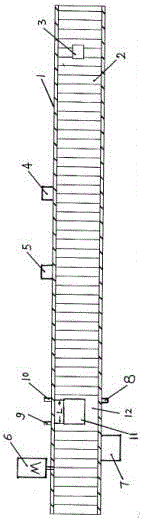

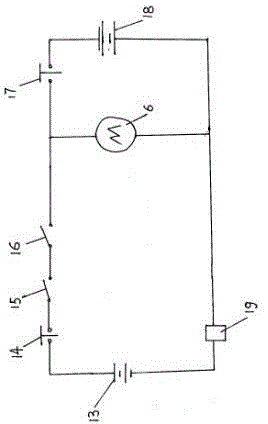

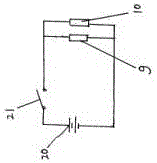

[0019] A urea finished product packaging conveying line capable of preventing code leakage, comprising a conveyor belt frame body 1, on which a conveyor belt 2 and a conveyor belt DC drive motor 6 are respectively arranged, and the conveyor belt DC drive motor 6 drives the conveyor belt The belt 2 runs, thereby driving the finished urea package on it to be transported from right to left. A urea discharge port 3 is arranged above the right end of the conveyor belt frame body 1. On the conveyor belt frame body 1 on the left side of the urea discharge port 3 A packaging bag sewing machine 4 is provided, a packaging bag inkjet printer 7 and an inkjet printer induction switch 8 are respectively provided at the left end of the conveyor belt frame body 1, and a coding area 12 is provided at the left end of the conveyor belt frame body 1. The belt 2 is provided with a finished urea pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com