BNC connector nut gripper/driver

A clamping structure, screw technology, applied in the direction of joint/disconnection of connection devices, screwdrivers, motor tools, etc., can solve problems such as difficult to use, wrong buckle, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Exemplary embodiments incorporating one or more aspects of the invention will be described and illustrated in the drawings. These illustrated examples are not intended to limit the invention. For example, one or more aspects of the invention may be used in other embodiments and even in other types of devices. In addition, the specific terms used in this specification are only for the convenience of description, and are not considered to limit the present invention. Also in the drawings, like reference numerals are used to designate like elements.

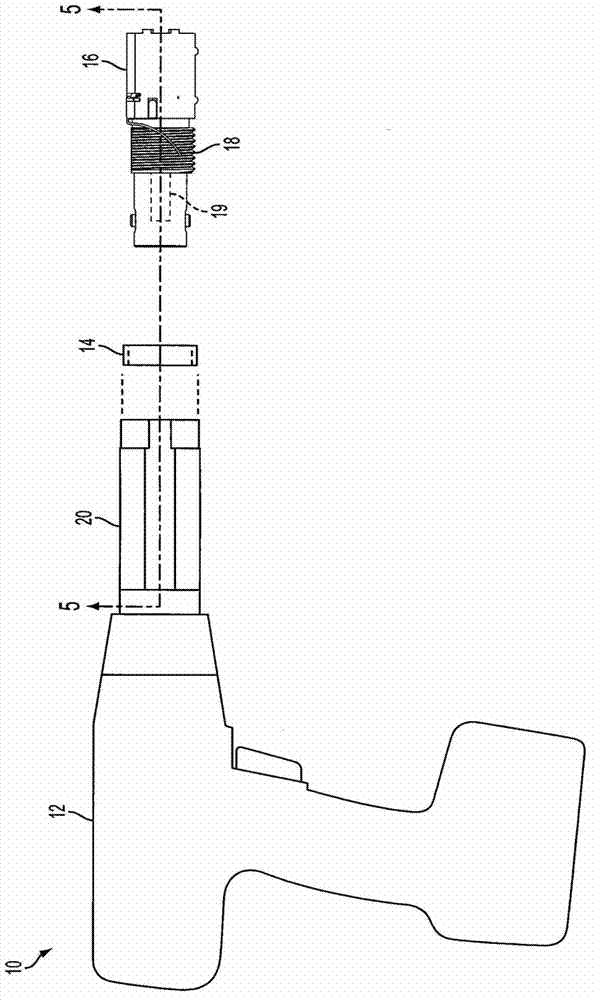

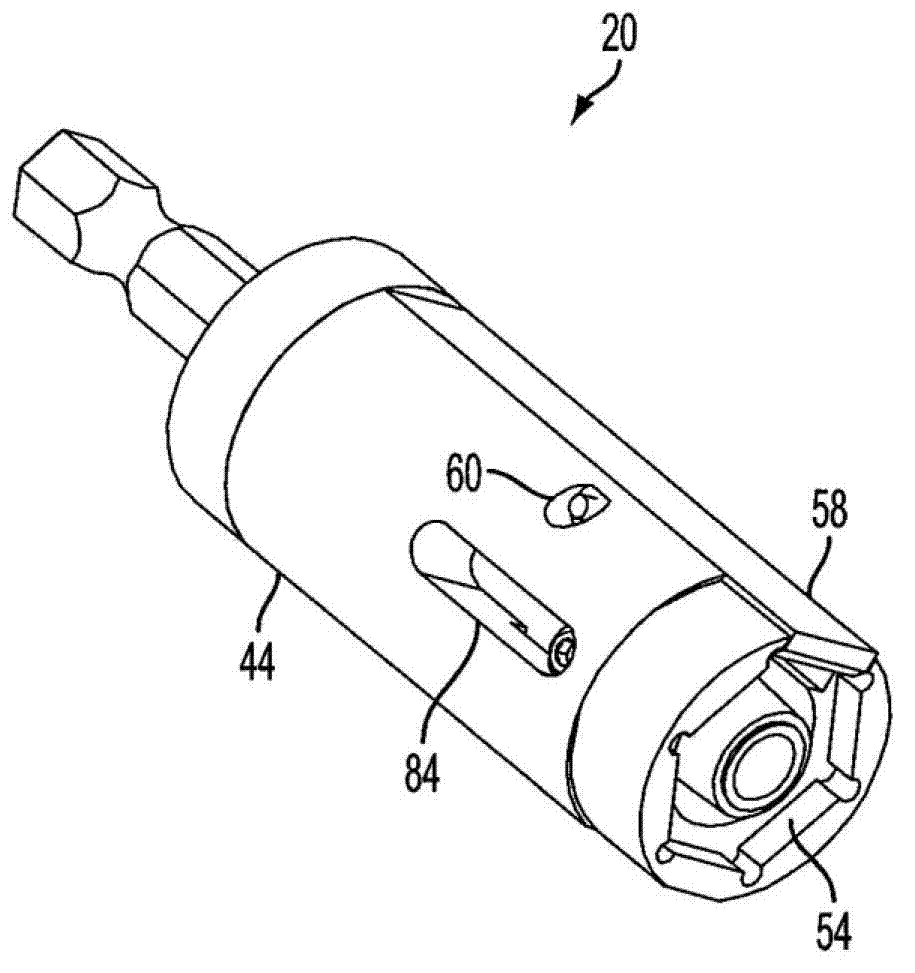

[0016] figure 1 An exemplary attachment apparatus 10 for attaching a fastener 14 to a receiving structure 16 such as a BNC connector or other similar connector is schematically shown. Briefly, socket assembly 20 is rotatably attachable to a power tool, such as drill 12 . The receptacle assembly 20 may be axially aligned with the receiving structure 16 when retaining the fastener 14 . The receptacle assembly 20 is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com