A Large-Scale Job Shop Scheduling Method Based on Bottleneck Equipment Decomposition

A job shop, scheduling method technology, applied in genetic models, data processing applications, forecasting, etc., can solve problems such as low efficiency, unsatisfactory quality, and poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

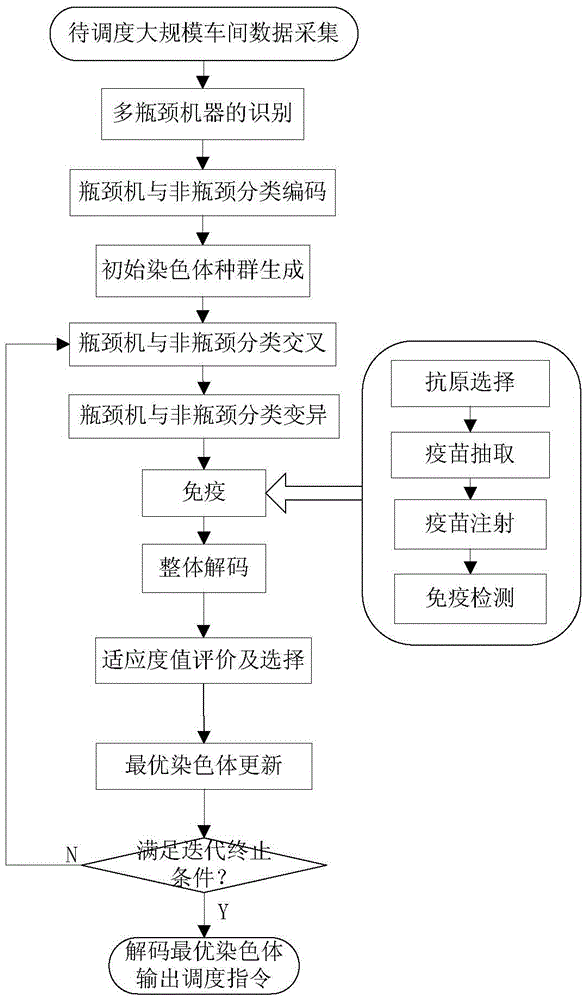

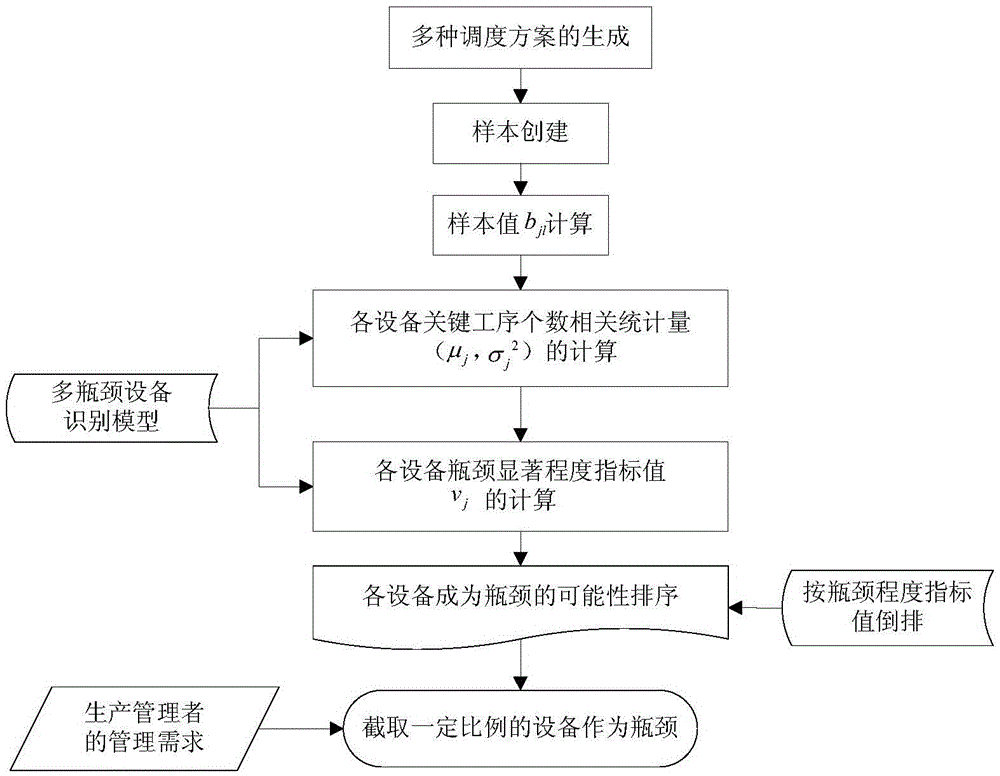

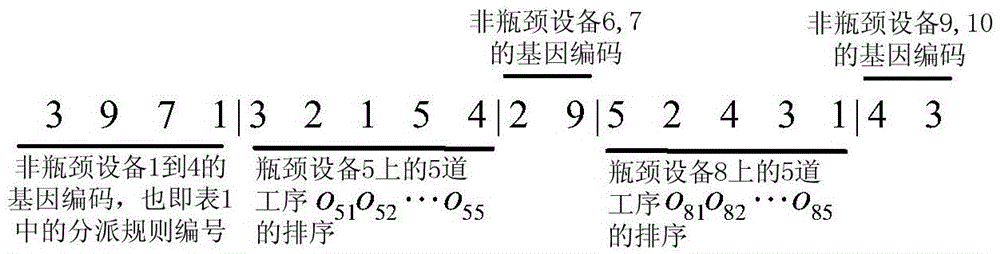

[0171] see Figure 1 to Figure 7 As shown, a large-scale job shop scheduling method based on bottleneck equipment decomposition of the present invention includes the following steps:

[0172] (1) Data collection; collect the number of equipment and workpieces to be dispatched in a large-scale operation workshop, the processing procedures of each workpiece, the processing time of each procedure, as well as the processing sequence between procedures, equipment processing capacity, and operation goals (minimize delay time and) constraint information. The large-scale operation workshop refers to a workshop with the number of machine tools ≥ 20 and the number of workpieces ≥ 50.

[0173] There are n workpieces in the job shop that need to be processed on m equipment, and workpiece i (i=1...n) contains N i (i=1...n) processes, each process has a sequence constraint between processes, and can be processed at most once on each equipment j (j=1...m) (N i ≤m). o i,j Indicates the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com