System calibration method for grating projection three-dimensional measurement

A technology of three-dimensional measurement and system calibration, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low precision, poor operability, and inability to accurately locate the three-dimensional measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The present invention establishes a calibration model of the system when the projector and the camera satisfy certain positional relationship constraints, and further obtains the calibration parameters by using the standard block and its absolute phase distribution. In the example, a trapezoid containing four squares with known heights is used as the calibration block, such as Figure 4 The trapezoidal object shown in .

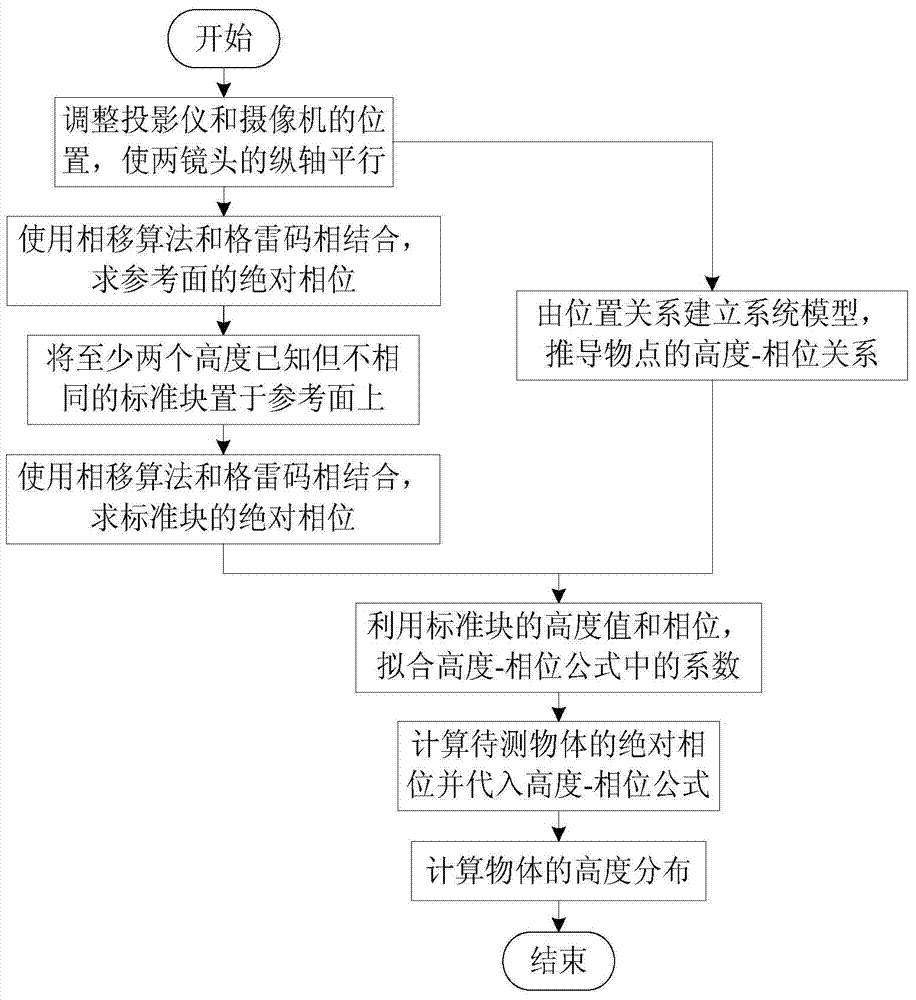

[0052] figure 1 It is a flowchart of the whole process of the present invention.

[0053] Calibration is a crucial step in the three-dimensional measurement of grating projection. The existing calibration methods have strict requirements on the positional relationship between the projector and the camera, but these positional constraints are difficult to achieve, which restricts the accuracy of the three-dimensional measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com