Antibacterial hand sanitizer and preparation method thereof

A technology of hand sanitizer and composition, which can be used in pharmaceutical formulations, topical antibacterial agents, cosmetic preparations, etc., and can solve problems such as limiting surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

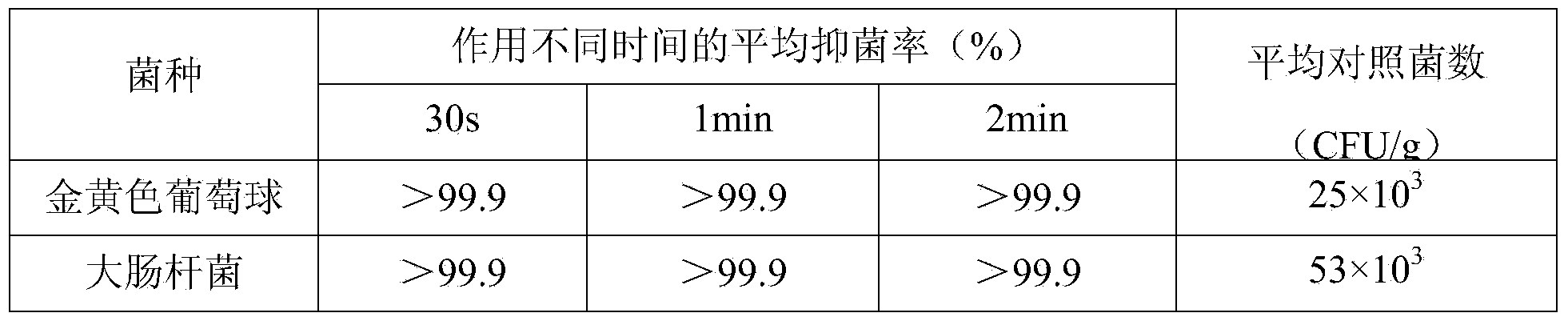

Image

Examples

Embodiment 1

[0024] A kind of antibacterial hand sanitizer, it comprises each raw material component of following percentage by weight:

[0025] Sodium Lauryl Sulfate 6%; Lactic Acid 0.1%;

[0026] Cocamidopropyl Betaine 4%; Preservatives 0.1%;

[0027] Propylene Glycol 3%; Sodium Chloride 0.5%;

[0028] Zinc Cocoth Sulfate 2%; Fragrance 0.2%;

[0029] Disodium EDTA 0.1%; Deionized water Add to 100%.

[0030] The preparation process of above-mentioned antibacterial hand sanitizer is:

[0031] Add an appropriate amount of water into the reaction tank, add sodium lauryl sulfate, cocamidopropyl betaine, propylene glycol, disodium edetate, stir well until completely dissolved, add lactic acid to adjust the pH to 3.5-4.5 ;Continue to add fungicide zinc cocoeth sulfate, preservatives, essence, and finally adjust to the required viscosity with sodium chloride, stir evenly and then fill.

Embodiment 2

[0033] A kind of antibacterial hand sanitizer, it comprises each raw material component of following percentage by weight:

[0034] Sodium Lauryl Sulfate 6%; Lactic Acid 0.05%;

[0035] Sodium Cocoamphoacetate 3%; Preservatives 0.1%;

[0036] Propylene Glycol 3%; Sodium Chloride 1.0%;

[0037] Zinc Cocoth Sulfate 5%; Fragrance 0.2%;

[0038] Disodium EDTA 0.1%; Deionized water Add to 100%.

[0039] The preparation process of above-mentioned antibacterial hand sanitizer is:

[0040] Add appropriate amount of water into the reaction tank, add sodium lauryl sulfate, sodium cocoamphoacetate, propylene glycol, ethyl alcohol diamine Disodium tetraacetate, stir well until completely dissolved, add lactic acid to adjust the pH to 3.5-4.5; continue to add fungicide zinc cocoeth sulfate, preservatives, flavors, and finally adjust to the required viscosity with sodium chloride, Stir well and then fill.

Embodiment 3

[0042] A kind of antibacterial hand sanitizer, it comprises each raw material component of following percentage by weight:

[0043] Fatty alcohol polyoxyethylene ether sodium sulfate 5%; Lactic acid 0.05%;

[0044] Cocamidopropyl Betaine 5%; Preservatives 0.1%;

[0045] Propylene Glycol 3%; Sodium Chloride 1.0%;

[0046] Zinc Cocoth Sulfate 5%; Fragrance 0.2%;

[0047] Disodium EDTA 0.1%; Deionized water Add to 100%.

[0048] The preparation process of above-mentioned antibacterial hand sanitizer is:

[0049] Add an appropriate amount of water into the reaction tank, add sodium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl betaine, propylene glycol, disodium edetate, stir well until completely dissolved, add lactic acid to adjust the pH to 3.5 ~4.5; continue to add fungicide zinc cocoeth sulfate, preservatives, flavors, and finally adjust to the required viscosity with sodium chloride, stir well and then fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com