Cotton bale conveying vehicle

A technology for transporting vehicles and cotton bales, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc. It can solve the problems of injury to transporters, falling, labor, etc., so as to increase safety, prolong service life, and reduce the occurrence of injuries rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

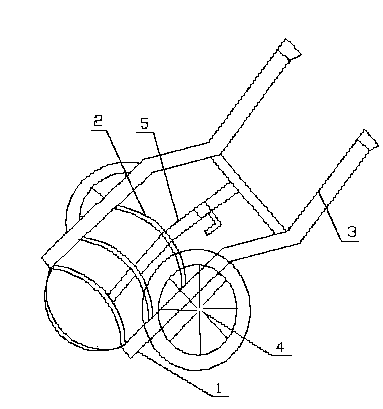

[0009] Such as figure 1 As shown, it includes two parallel longitudinal beams 1 and a frame body formed by connecting multiple beams 2, and handlebars 3 and wheels 4 installed on the frame body, and reinforcing ribs are also provided between the beams 2. 5. The shape of the plurality of beams 2 is a concave arc matching the shape of the cotton bag.

[0010] continue as figure 1 As shown, the reinforcing rib 5 provided between the beams 2 is used to prevent the transport vehicle from being damaged due to the excessive weight of the cotton bale and affect the service life of the transport vehicle.

[0011] The shape of the crossbeam 2 is a concave arc that matches the shape of the cotton bale body. The purpose is to hold up the handlebar 3 of the frame during use, and the cotton bale will be firmly fixed between the two crossbeams under its own gravity. , so that the safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com