Preparation method of pine needle flavone

A technology of pine needles and flavonoids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

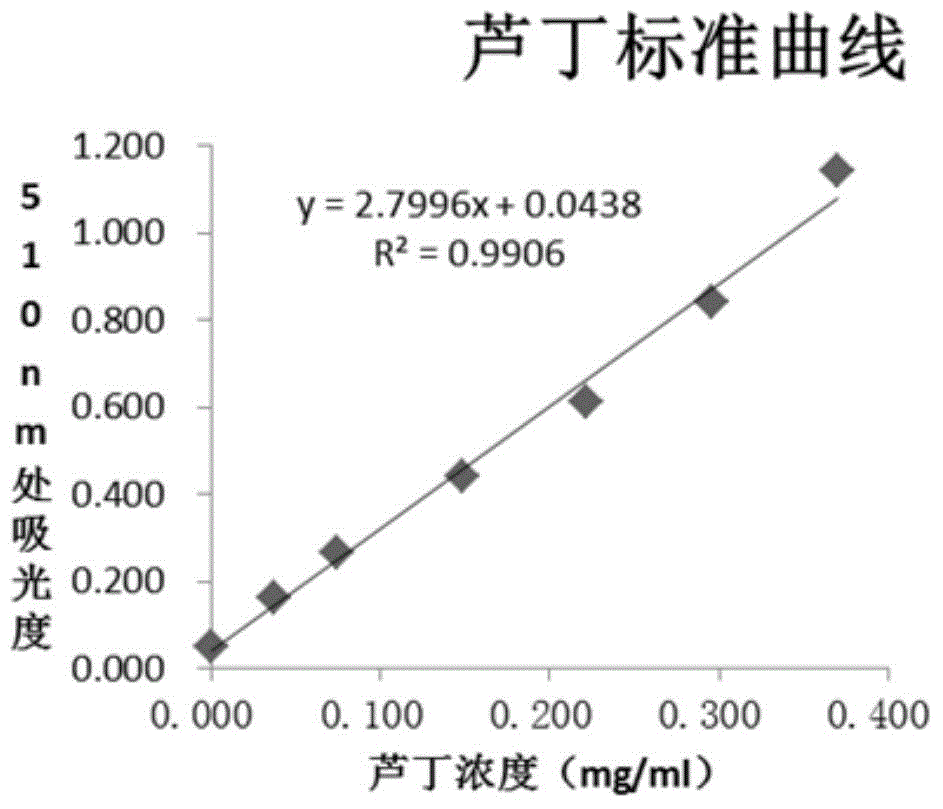

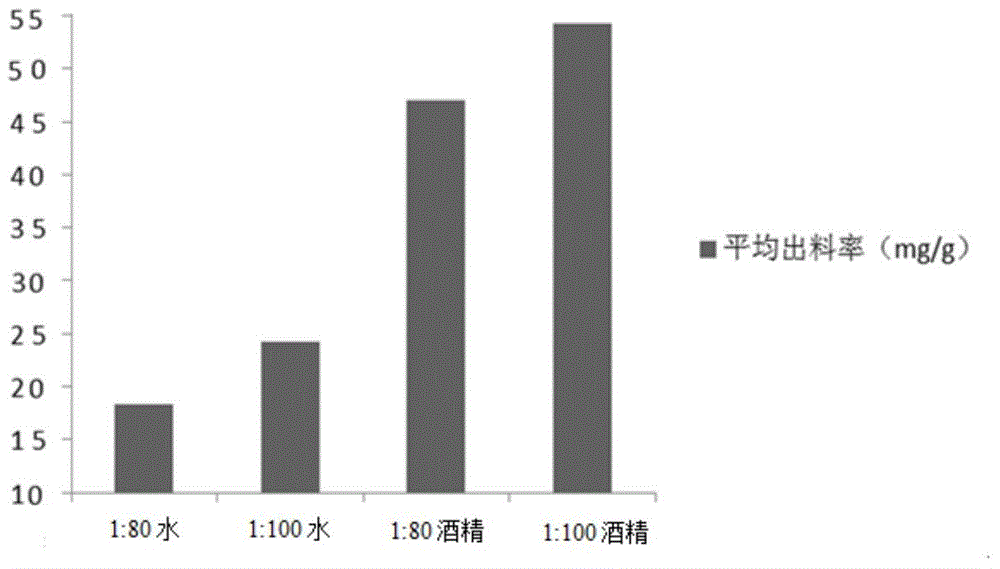

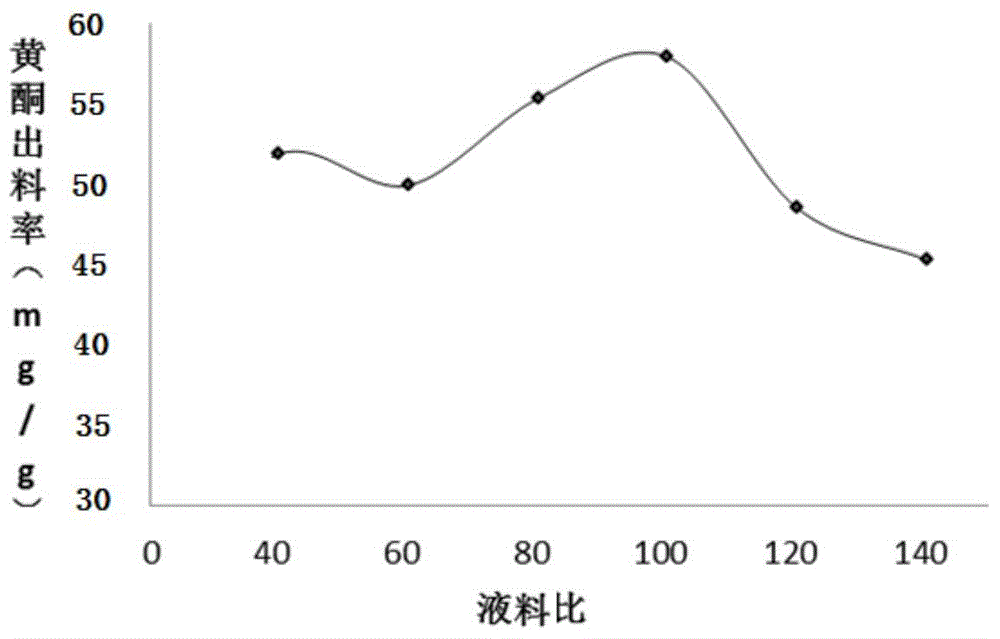

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of raw materials: select the larch needles of Masson pine produced in Zhejiang Province, remove the impurities, wash and dry at 60°C, and turn it from time to time. After the pine needles become brittle, take them out and crush them, sieve them, and take 20- 40 mesh, 40-100 mesh, 100-150 mesh, 150-200 mesh, 200-300 mesh, more than 300 mesh powder, refrigerated and ready for use.

[0043] 2. Reagents: ethanol, standard rutin, sodium nitrite, aluminum nitrate, sodium hydroxide, hemicellulase (3000u / g), cellulase (40000u / g).

[0044] 3. Instruments: HMB-701C pulverizer, H1650 high-speed centrifuge, DZF-6050 vacuum drying oven, DK-8D electric heating constant temperature water tank (temperature fluctuation: ±0.5°C), RE-52A rotary evaporator, AL-104 electronic balance ( Graduation value: 0.0001g), UV-2100 ultraviolet-visible spectrophotometer, HH-2 digital display constant temperature water bath, ZXE-Z rotary vane vacuum pump, vortex oscillator, etc.

[0045]...

Embodiment 2

[0136] Processing of raw materials: Take 10g of dry pine needle powder (with a particle size of 150-200 mesh), add citric acid-sodium citrate buffer solution (0.1mol / L) 40 times the mass of pine needle dry powder (400g), mix well to obtain a mixture , add 0.1% cellulase (enzyme activity: 40000u / g) in the mass of the mixture, and ultrasonically hydrolyze for 120 minutes at 45°C and pH 5.0, then add 5% hemicellulase (enzyme activity) in the mass of the mixture 3000u / g), raise the temperature to 50°C, and then ultrasonically hydrolyze for 90 minutes, raise the temperature to 90°C and keep it for 5 minutes, then lower it to 80°C, add 700g of 79% ethanol aqueous solution for extraction, ethanol aqueous solution and lemon The mass ratio of the total mass of the acid-sodium citrate buffer solution to the dry powder of pine needles is 110:1, extracted at a temperature of 78°C for 128min, then centrifuged, and the flavonoid content in the supernatant was detected to be 72.24mg / g, filter...

Embodiment 3

[0138] Processing of raw materials: Take 10g of dry pine needle powder (with a particle size of 150-200 mesh), add citric acid-sodium citrate buffer solution (0.1mol / L) 40 times the mass of pine needle dry powder (400g), mix well to obtain a mixture , add 0.5% cellulase (enzyme activity: 40000u / g) in the mass of the mixture, and ultrasonically hydrolyze for 90 minutes at 45°C and pH 5.0, then add 1% hemicellulase in the mass of the mixture (enzyme activity 3000u / g), raise the temperature to 55°C, and then ultrasonically hydrolyze for 150min, then raise the temperature to 90°C and keep it for 5min, then lower it to 80°C, add 700g of 79% ethanol aqueous solution for extraction, ethanol aqueous solution and lemon The mass ratio of the total mass of the acid-sodium citrate buffer solution to the dry powder of pine needles is 110:1, extracted at a temperature of 78°C for 128min, and then centrifuged to detect that the flavonoid content in the supernatant is 69.17mg / g, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com