A kind of precured glass fiber cloth impregnation material and preparation method thereof

A technology of glass fiber cloth and impregnating material, which is applied in the field of pre-cured glass fiber cloth impregnating material and its preparation, which can solve the problems of short storage time, high brittleness and low toughness of composite material products of pre-impregnated materials, and achieve good commercial effect and performance Good, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

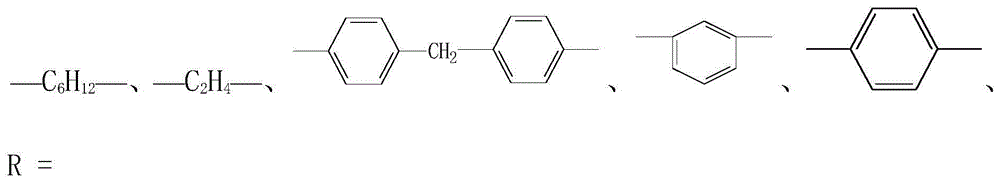

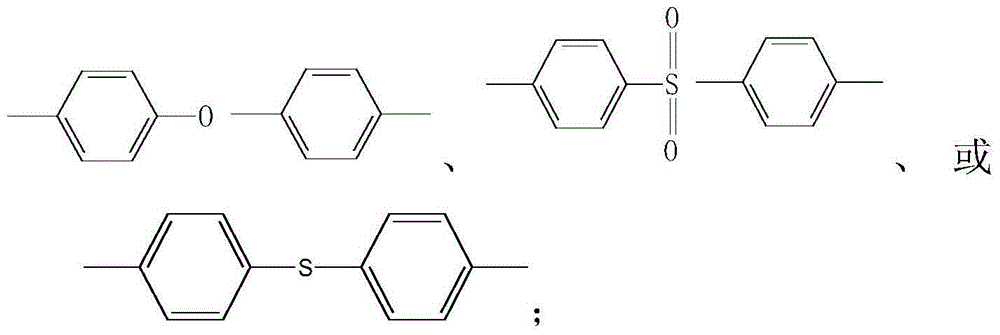

Method used

Image

Examples

Embodiment 1

[0059] Put 160kg of amine compounds (aniline: m-phenylenediamine: 1,6 hexamethylenediamine = 4:3:1), 100kg of maleic anhydride and 375kg of toluene into the reactor, and heat up rapidly under stirring React at 80°C for 1 hour, cool down to 5°C-9°C, then add 250kg of formaldehyde solution (40%), control the temperature not to exceed 30°C and react for 0.5-1 hour, adjust pH = 6-8, then add 165kg Phenolic compounds (phenol:cardanol=4:1) and 125kg toluene, stirred and reacted at 85°C for 2 hours, separated into organic phase and water phase after standing, removed the water in the lower part of the reactor, and added 375kg of acetone , and stirred for 0.5 hours to obtain a benzene-horse resin solution.

Embodiment 2

[0061] Put 160kg of amine compounds (aniline: m-phenylenediamine = 4:3), 100kg of maleic anhydride and 375kg of toluene into the reactor together. Under stirring, rapidly raise the temperature to 80°C for 1 hour, then cool down to After 22°C~25°C, add 250kg of formaldehyde aqueous solution (40%), control the temperature not to exceed 30°C for 0.5~1 hour, adjust the pH=6~8, and then add 160kg of phenolic compounds (phenol: cresol = 1:2) and 125kg of toluene, stirred and reacted at a temperature of 85°C for 2 hours, separated into an organic phase and an aqueous phase after standing still, removed the water in the lower part of the reactor, added 375kg of acetone, stirred for 0.5 hours, and obtained benzene-matrix resin solution.

Embodiment 3

[0063] Put 190kg of amine compounds (aniline: 1,6 hexamethylenediamine = 2:3), 100kg of maleic anhydride and 420kg of toluene into the reactor together, and rapidly raise the temperature to 70°C for 1.5 hours under stirring. After cooling down to 15°C-18°C, add 280kg of formaldehyde aqueous solution (40%), control the temperature not to exceed 30°C and react for 1 hour, adjust pH = 6-8, then add 190kg of phenolic compounds (phenol: cardanol = 5:1) and 140kg of toluene, stirred and reacted at a temperature of 95°C for 5 hours, separated into an organic phase and an aqueous phase after standing still, removed the water in the lower part of the reactor, added 420kg of acetone, stirred for 0.5 hours, and obtained benzene-matrix resin solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com